DISTRIBUTED ENERGY RESOURCES KEY to a low carbon future

WATER SEWER ELECTRICITY GAS Engineering, Construction & Maintenance www.utilitymagazine.com.au Issue #33, February 2022

Highlights from SYDNEY WATER’S INNOVATION FESTIVAL How cybersecurity regulatory changes will impact you

The world’s first and only CAT III 1500 V clamp meter

Whether it’s solar/wind farms, electric railways or battery banks – the Fluke 393 FC is designed for uninterruptable, high voltage DC environments.

• Measure safely with CAT III 1500 V rated clamp meter

• Thin jaw for access to cables in crowded combiner boxes

• Rugged construction & sturdy IP54 rated for outdoor use

• Work efficiently with DC power measurement, audio polarity & visual continuity

• Record, analyse & share results with Fluke Connect™ software

Learn more fluke.co/393FCU

FROM THE EDITOR

It’s strange to be writing this editor’s letter in 2022 – it feels like it was 2020 only yesterday. As this is the first issue of the magazine for this year, all of our contributors have naturally taken a future planning angle; looking ahead to what new innovations, projects and industry developments are in store for utilities. The big focus across water and energy is implementing digital technologies to increase efficiency, as well as the move to more sustainable and resilient systems.

All of these new technological innovations come back to data – what are we collecting, who has access to it, and how are we analysing it to actually give us valuable insights into operational decision making? Both the Centre for New Energy Technologies and Intelligent Water Networks explore this in our Big Data feature.

These questions tie in heavily with current energy transitions happening across the country. This edition takes a deep dive into these topics, looking at how we can maximise distributed energy resources (DER) using state estimation, flexible connection arrangements in solar, Horizon Power’s journey to net zero in regional WA, as well as comprehensive coverage of the major DER projects around Australia.

Over in the water sector, Sydney Water held its inaugural Innovation Festival recently which brought together water utilities and stakeholders to generate new ideas to solve key challenges. It

focused on six themes: the circular economy, liveability, water security, smart cities, customer experience and amplifying the voices of Aboriginal Peoples, and we have all of the highlights and outcomes from the event on page 56.

All of these digital technologies and new processes are a great step forward in increasing the productivity of the utility industry, but they all come back to one main purpose – customers. We are also featuring the latest processes the energy and water sectors are undertaking when it comes to elevating customer service and engagement.

One thing the Utility team and I are the most excited about this year is the prospect of in-person industry events coming back. A significant number of events that have been canceled or postponed over the last two years are set to run again in the first half of 2022, including WIOA, Energy Networks and Locate22, in addition to other planned events including Ozwater'22. I look forward to meeting some of you in person at these industry conferences.

I’m also excited to announce that Utility magazine will be running Digital Utilities again this year as a virtual event in June. Keep your eye on the Utility website and weekly newsletter for more announcements on the event soon, or reach out if you are interested in being involved.

Jessica Dickers Editor

Drop me a line at jessica.dickers@monkeymedia.net.au or feel free to call me on 03 9988 4950 to let me know what you think.

Don't forget to follow Utility magazine on social media - find us on LinkedIn, Twitter and YouTube.

UTILITY • FEBRUARY 2022 Editor Jessica Dickers Assistant Editor April Shepherd Journalists Annabelle Powell Lauren DeLorenzo Christopher Allan Design Manager Alejandro Molano Designers Danielle Harris Luke Martin Business Development Managers Rima Munafo Brett Thompson Marketing Manager Radhika Sud Publisher Chris Bland Managing Editor Laura Harvey Published by Cover image highlights our features on distributed generation, solar and customer experience. DISTRIBUTED ENERGY RESOURCES KEY to a low carbon future Highlights from SYDNEY WATER’S INNOVATION FESTIVAL How cybersecurity regulatory changes will impact you UTILITY MAGAZINE FEBRUARY 2022 WATER SEWER ELECTRICITY GAS Engineering, Construction & Maintenance www.utilitymagazine.com.au Issue #33, February 2022 Monkey Media Enterprises ABN: 36 426 734 954 C/- The Commons 36–38 Gipps St, Collingwood VIC 3066

(03)

welcome February 2022 ISSUE 33 1

P:

9988 4950 monkeymedia.com.au info@monkeymedia.com.au utilitymagazine.com.au info@utilitymagazine.com.au ISSN: 2203-2797

What pipe is most appropriate for different microtunnelling projects?

Pipe selection can make or break a project so to speak; the wrong pipe can make a project more difficult to complete, increase time and costs, or at worst, fail, while the right pipe will help reduce risk, enhance accuracy, reduce cost and improve the overall success of installation. But with a number of pipe materials available, how do you know which one is right for your application? This will come down to a number of factors – some of which have a greater impact than others – including ground conditions along the route of the pipeline, method of installation, budget, application type, deadline and specifications such as diameter.

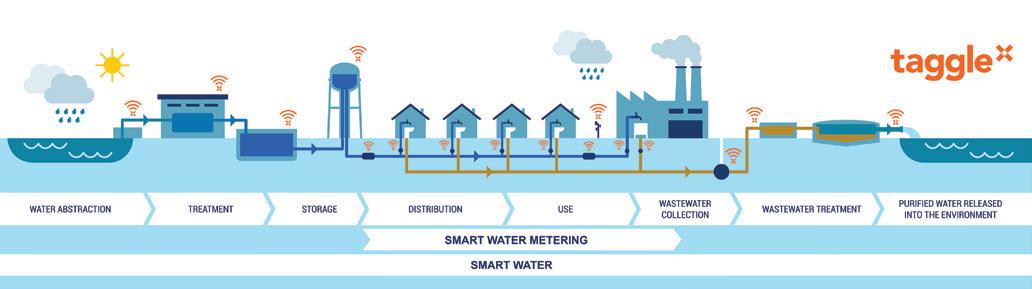

2 CONTENTS Big data supporting the new energy paradigm 32 Combating network leaks with digital technology 34 Data innovations for the water industry 36 Charting a path for utility digital transformation 38 Identifying critical differences between Smart Water Metering and Smart Water ......................... 40 How amendments to the Security of Critical Infrastructure Act will impact your utility 42 Every year, organisations are spending more and more money on their security defences. But every year, we see the frequency and severity of cyber attacks against Australia continue to increase. SOLAR Flexible energy resources key to a low carbon energy future........ 44 The world’s only CAT III 1500 V current clamp 48 Transitioning to a water resilient Harbour City 50 Creating the future of water for councils and communities 54 Highlights from Sydney Water’s Innovation Festival 56 Fully automated iron measurements for cost-effective water analysis ............................. 58 The role of desalination in Australia’s changing climate ..... 60 Managing pressure in water networks using polymer valves 62

EnergyConnect: meeting the challenges of a remote environment ................................ 88 50 years of substation civil and cable works 90 Using ACB retrofit solutions to ensure stable power supply 92 CUSTOMER EXPERIENCE Yarra Valley Water elevating customer service with new technology .......................... 94 Customers at the centre of the energy sector 96 DRONES Eye in the sky helping Powercor manage network inspections 100 94 88 50 42 32 102 UTILITY • FEBRUARY 2022 WWW.UTILITYMAGAZINE.COM.AU SYDNEY WATER BIG DATA CYBER SECURITY

SWITCHGEAR

February 2022 ISSUE 33 3 80 In each issue Welcome from the Editor ������������������������������������������������������������������������������������������������������������� 1 A word from Energy Networks Australia ���������������������������������������������������������������������������������� 4 A word from WSAA ����������������������������������������������������������������������������������������������������������������������� 6 News briefs ������������������������������������������������������������������������������������������������������������������������������������ 8 Advertisers’ index �������������������������������������������������������������������������������������������������������������������� 104 Editorial schedule �������������������������������������������������������������������������������������������������������������������� 104 Implementing Victoria’s embedded networks ban 64 DISTRIBUTED GENERATION Maximising Distributed Energy Resources using State Estimation 66 Journey to net zero well underway in regional WA 68 Mapping the future of distributed energy resources ......................... 70 Satellites providing unparalleled accuracy in dam surveillance 74 Dams play a critical role in securing our water supply, so it’s vital that issues such as seepage – which threaten their integrity – are detected as early as possible. Here, Utility explores how Hunter Water has employed innovative satellite technology to increase the accuracy of its dam monitoring. Cadastre modernisation energises GIS ............................... 76 Managing utilities with aerial imagery .............................. 78 The importance of sewer rehabilitation 80 Sewer rehabilitation – the repair or renewal of an existing sewerage asset –has both short and long-term advantages for sound management of Australia’s wastewater networks. As asset operators continue to leverage the many benefits of sewer rehabilitation, here we consider some of the different projects occurring around the country, revealing how each project draws on a unique technical approach. Temporary solution for a wastewater plant 84 Weld-free repair offerings making waves in the industry 86 64 74 UTILITY • FEBRUARY 2022 WWW.UTILITYMAGAZINE.COM.AU EMBEDDED NETWORKS MAPPING, GIS AND SURVEYING SEWER REHABILITATION

STACKING UP – HOW DO WE COMPARE?

by Chris Gilbert, Senior Economic Advisor, Energy Networks Australia

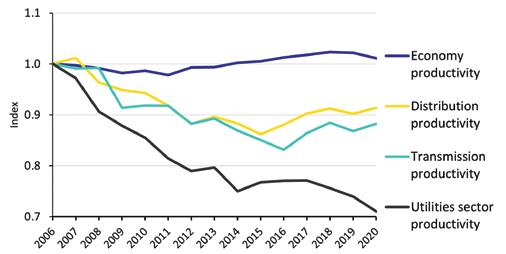

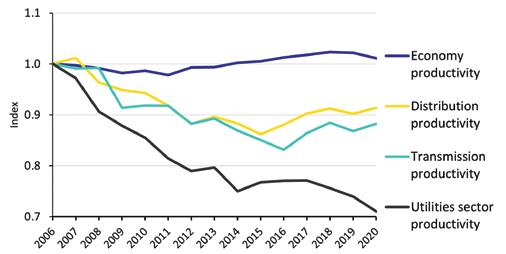

Electricity networks in the National Electricity Market (NEM) are continuing to deliver more for less as demonstrated in the recently released Australian Energy Regulator (AER) 2021 Benchmarking reports.

But is benchmarking working to deliver the best transparency and outcomes for customers, and what can be done to improve the reliability and applicability of its results?

The reports detail each network business’ productivity using several inputs and outputs, including the amount of assets, operating expenditure (opex), reliability, number of customers, maximum demand, total energy delivered and how far electricity is transported. They include information up to 2020 for Victorian distribution networks, and 2019-20 for non-Victorian distribution and transmission networks, referred to collectively as 2020.

An increase in productivity from a customer perspective means either lower bills, improved services, or both. Productivity is an important metric for regulators that is used during revenue determinations to ensure that network businesses’ revenues reflect the efficient cost of service provision.

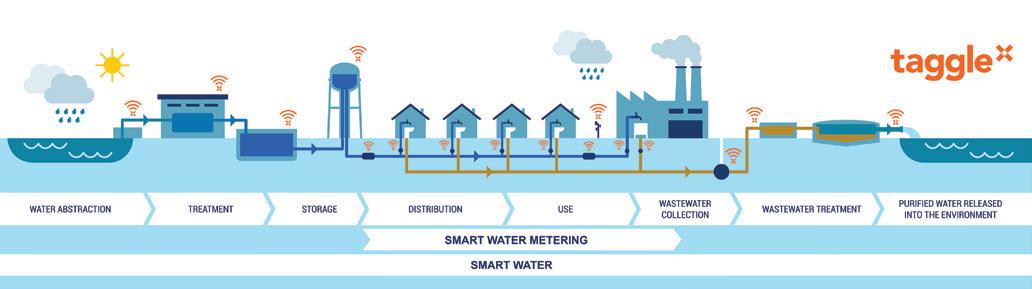

DELIVERING MORE FOR LESS

Overall, distribution and transmission network productivity increased by 1.2 per cent and 1.7 per cent in 2020 respectively, continuing the trend of steady improvements made since 2015 and 2016. Notably for both distribution and transmission networks, overall inputs reduced, and overall outputs increased in 2020 compared with 2019.

Interestingly, this is contrasted with a trending decline in productivity across the wider utility sector since 2017, where productivity has fallen by eight per cent. Economywide productivity also fell marginally over 2019 and 2020, presumably due to the pandemic. Electricity network companies seem to have navigated the period well in relative terms and have managed to avoid similar reductions.

PRODUCTIVITY OF NETWORKS, ECONOMY AND UTILITIES, INDEXED

The long-term productivity trend for all distribution networks appears to be converging, meaning the gap between higher and lower performers is narrowing. The shorter-term trend across distribution and transmission networks is that networks with lower productivity are improving, pushing closer towards ‘middle of the road’ performers.

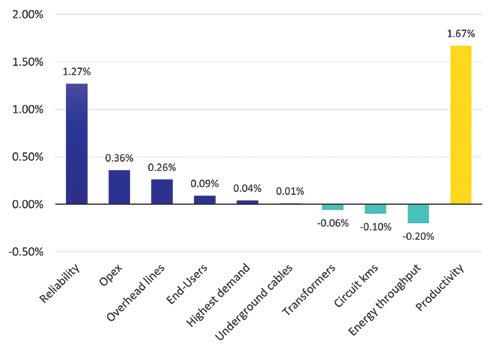

OPEX SAVINGS AND RELIABILITY IMPROVEMENTS LEADING OUTCOMES

Most distribution productivity increases in 2020 resulted from reductions in opex, contributing positively to productivity by 1.8 per cent. Opex savings have been the predominant driver of distribution productivity improvements since 2015, with 3.1 per cent contributions to productivity a year. Opex productivity has been increasing by 3.1 per cent each year, which all else being equal will lead to lower revenue allowances in the future.

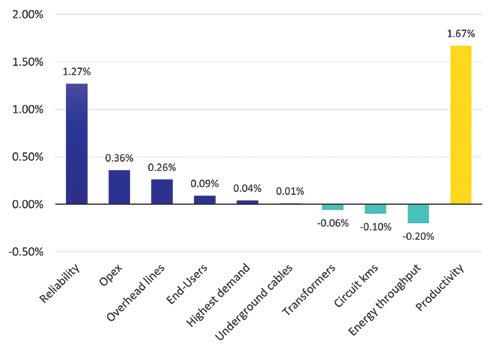

DISTRIBUTION PARTIAL PRODUCTIVITY MEASURES, 2020 VS 2019

Transmission productivity improvements were led by higher reliability, recognised formally as lower unsupplied energy to customers. Smaller positive contributions to productivity were made by lower opex, fewer overhead lines and more customers.

4 A WORD FROM ENERGY NETWORKS AUSTRALIA

TRANSMISSION PARTIAL PRODUCTIVITY MEASURES, 2020 VS 2019

GETTING BENCHMARKING RIGHT FOR CUSTOMERS

Benchmarking can be one of multiple tools for regulators and customers to understand how network businesses have been performing, but like most measures, the results are only as useful as the appropriateness of the inputs and analysis.

There are also some differences in how networks treat their opex and capital expenditure, which has led the AER to release a separate consultation paper on the issue.

There are also issues with some econometric models that compare the relative efficiency of network businesses. These models assume that an increase in output can only be achieved with an increase in inputs, but when network businesses deliver more by using less, some of the models break.

The AER has an ongoing benchmarking development program looking at incremental improvements in data and methods, as well as focusing on specific issues such as those outlined above that could improve the reliability and applicability of benchmarking results. Improvements to the benchmarking program are highly sought after by industry.

MORE TO BE DONE

ABOUT US

Edge Underground is a precision microtunnelling contractor that operates in Australia and the USA. With a focus on innovative technology and expertise, Edge Underground designs and enhances the performance of trenchless equipment.

Productivity improvements delivered by network businesses are good news for customers, leading to improved service delivery or lower revenue allowances. Ensuring that benchmarking appropriately recognises the types of services customers value is in customers’ interest as benchmarking results are considered during revenue determinations. Addressing some of the underlying inconsistencies between benchmarking methodology and delivering network services in practice will be key during the AER’s benchmarking development program.

•

OUR SERVICES

Microtunnelling

Pipe Jacking

Thrust Boring

Laser Tunnel Boring

•

•

•

•

Box Culvert Jacking

Canopy Tubes GUIDED BORING SPECIALISTS * quotes@edgeunderground.co 8 www.edgeunderground.co ( JACKED 1300 522533

•

A WORD FROM WSAA

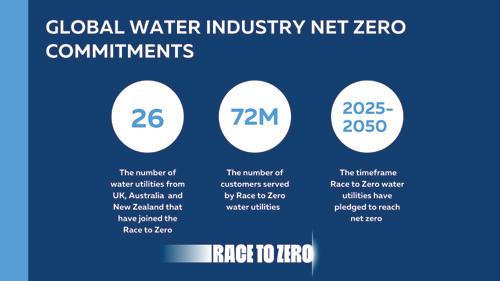

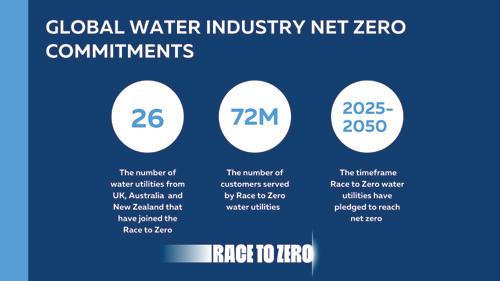

WATER UTILITIES UNITE IN RACE TO ZERO

The IPCC Assessment Report 6 describes the current outlook on climate change as a ‘code red for humanity’. Over the last few years, Australia and New Zealand have seen record breaking droughts and floods. Urban water utilities and the communities they serve are no strangers to the huge impact climate change is already exerting on water supplies.

Together with Water UK, 13 Australian and one New Zealand water utilities have joined the UN-led Race To Zero campaign, adding their voice to the global message that industry is tackling climate change, alongside major UK water utilities.

Australian and New Zealand utilities have joined their counterparts from the UK who have also pledged to reach net zero emissions by 2050 or earlier, with interim targets within the next decade. Combined, these utilities serve over 72 million people in Australia, New Zealand and the UK.

The 14 participating utilities are:

• Barwon Water

• Coliban Water

• Gippsland Water

• Goulburn Valley Water

• Icon Water

• Melbourne Water

• SA Water

• South East Water

• Southern Rural Water

• Sydney Water

• Unitywater

• Urban Utilities

• Watercare (New Zealand)

• Yarra Valley Water

Globally, water use, storage and distribution are responsible for around 10 per cent of global greenhouse gas (GHG) emissions. Water services also produce around 5-8 per cent of global methane emissions. The water industry has a central role to play in reducing emissions, but is also in a unique position to produce renewable energy.

In joining the Race To Zero pledge, the industry is showing its leadership and commitment to mitigating the impacts climate change. Many utilities are already early adopters of wind, solar and waste to energy technology to power their infrastructure.

CURRENT INNOVATIONS

In addition to these 14 utilities from Australia and New Zealand, there are many other water utilities who are well on their way to contributing to a net zero future, and may join the Race To Zero campaign in the coming months.

The urban water industry is at the cutting edge of many innovations to reduce its carbon footprint, such as producing renewable energy from food waste, harvesting the valuable resources that can be recovered through wastewater treatment,

producing green hydrogen and ammonia which can be used as green fuels, using significant land corridors and reservoirs for solar panels, and transitioning to electric vehicles.

Some facts about the collective impact of the 14 Australian and New Zealand water utilities who have joined the Race To Zero include:

• They serve over 18 million customers

• Total of 160,000km of water and wastewater pipelines

• Total of 354 treatment plants

• Have pledged to reach net zero by 2025 to 2050

• Total net emissions: 847,637tCO2e*

• Total electricity use: 1,199,192 MWh*

• 175MW of existing solar assets

• 220MW of planned solar assets

The Race To Zero is a United Nationsbacked global campaign rallying non-state actors – including companies, cities, regions, financial and educational institutions – to take rigorous and immediate action to halve global emissions by 2030 and deliver a healthier, fairer zero carbon world.

*Some 2019/20 and some 2020/21 data

6 UTILITY • FEBRUARY 2022 WWW.UTILITYMAGAZINE.COM.AU

Untap the sustainability potential of digitising your network. ™

Gain real-time visbility of your water and wastewater networks with the NEW Captis Version 1.2. Your complete IoT monitoring and measurement solution - device, cloud, connectivity.

1800 646 828 | miot.com.au

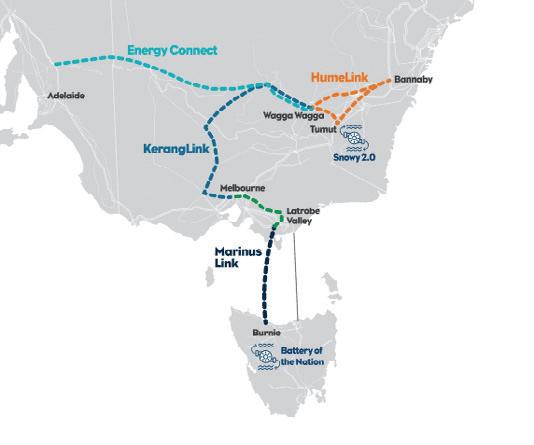

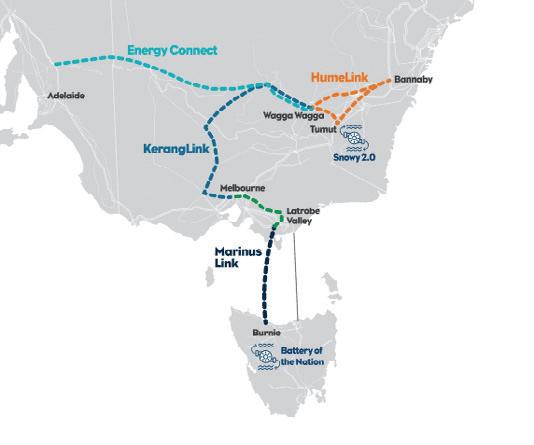

The Marinus Link Interconnector, a proposed project set to run between Victoria and Tasmania, has passed a major milestone – the $3.5 billion project submitting Federal and Victorian environmental referrals.

Project Marinus involves approximately 255km of undersea High Voltage Direct Current (HVDC) cable and approximately 90km of underground HVDC cable.

The project has made submissions for project assessment under:

$3.5B MARINUS LINK

INTERCONNECTOR REACHES MAJOR MILESTONE

Commonwealth Environment Protection and Biodiversity Conservation Act (EPBC Act) Victorian Environmental Effects Act (EE Act)

The current target date for commissioning and commercial operation of the first 750MW stage is 2027-28, with the commissioning and commercial operation of the second 750MW stage currently scheduled for 2029-30.

Marinus Link will cut at least 70 million tonnes of CO2 by 2040, the equivalent of taking approximately half a million cars off the road.

Upon review of the applications, both the Federal Minister for the Environment and the Victorian Minister for Planning will decide if further environmental assessments are required.

Marinus Link General Manager, Bess Clark, said, “Marinus Link is committed to sustainable development, and is following robust environmental, land use planning and cultural heritage assessment standards to minimise impacts that the project may create.

“We understand the importance of preserving the natural environment and protecting other values that communities have. We are invested in working closely with local residents, landowners, Traditional Owners and businesses to manage concerns and to listen to and learn from the local community.”

The Australian Energy Market Operator (AEMO) and the Federal Government have declared Marinus Link a national priority project.

The process for assessing Tasmanian environmental and planning matters will be determined in due course.

Innovative Water Solutions

WATER TECHNOLOGIES

Through its innovative solutions, Veolia Water Technologies enables industry, local authorities and citizens to optimize their use of resources for more efficient, environmentally-friendly and socially responsible outcomes.

We understand the importance of increasing the value of water and we do so by supplying high quality water, treating and reusing wastewater, producing and/or recovering energy, extracting raw materials and capitalizing on valuable byproducts.

www.veoliawatertechnologies.com.au

UTILITY • FEBRUARY 2022 WWW.UTILITYMAGAZINE.COM.AU 8

© Veolia Photo Library

NEWS

WWW.ACCESS DETECTION .COM .AU SOLUTIONS TO YOUR UTILITY PROBLEMS

• TELSTRA, NBN & DBYD COMPLIANT

• IMPROVED PERFORMANCE THROUGH NEW HARDWARE UPDATES

• TELSTRA, NBN & DBYD COMPLIANT IMPROVED PERFORMANCE THROUGH NEW HARDWARE UPDATES

• STANDARD LITHIUM ION BATTERIES IN RX & TX

• STANDARD LITHIUM ION BATTERIES IN RX & TX

• STANDARD PATHLINK RECEIVER TO TRANSMITTER COMS

• STANDARD PATHLINK RECEIVER TO TRANSMITTER COMS

• STANDARD PASSIVE MODES INCLUDING PASSIVE HARMONICS

• STANDARD PASSIVE MODES INCLUDING PASSIVE HARMONICS HIGH POWERED 12WATT

• HIGH POWERED 12 WATT TRANSMITTER

ANTENNA ARRAY

• PROFESSIONAL CLASS LOCATOR WITHOUT THE HIGH PRICE

PROFESSIONAL CLASS LOCATOR WITHOUT THE HIGH PRICE

NEXT GENERATION DUAL FREQUENCY SYSTEM SEE MORE CLEARLY

• COMPACT AND LIGHTWEIGHT BUT TOUGH DESIGN

• LARGE WHEELS FOR ROUGH TERRAIN ABILITIES

• VIEWPOINT ACQUISITION, SOFTWARE MADE EASY

• NO GIMMICKS JUST GOOD OLD FASHION PERFORMANCE

• SUPERIOR UTILITY DETECTION GPR SYSTEM FOR PROFESSIONALS

Raptor 3D GPRAmly

Raptor antennas offer a flexible way to configure multi-channel 3D GPR arrays from as few as 4-channels up to 30-channels as standard, or larger bespoke solutions upon request. Raptor antennas use modern real-time sampling technology to support high-speed and high-quality 3D data acquisition at speeds up to 130 km/h at 5 cm point intervals. Backed by Condor, our new 3D GPR processing and visualisation software, Raptor is a highly productive end-to -end 3D subsurface mapping solution.

Locate & Map Utilities Fast

• REDUCE RISK AND COSTS

• BOOST PERFORMANCE AND IMPROVE WORKFLOWS

• MINIMISE FIELD TIME AND OPTIM ISE DATA PROCESSING

• SIMPLIFY GPR DATA INTERPRETATION FOR MORE

• EFFECTIVE DECISION MAKING

• FLEXIBLE AND MODULAR ANTENNA CONFIGURATIONS

• ALLOW SWITCHING BETWEEN VEHICLE-MOUNT OR

• PUSH-CART CARRIERS

NEWRycom Pathfinder PR0+V3

I I ' •• �..,..~:·__.:._,'-

ACCESSDETECT(-N

PinPointR from Impulse RadarGPR

-impulse:.,� lmpulseRadar defines GPR

DIGITAL UTILITIES

RETURNS IN 2022

Utility magazine’s Digital Utilities conference will be held in June and once again bring together water and energy utility CEOs, CIOs and digital teams to exchange vital industry information. This year’s conference will run virtually, in addition to a live awards ceremony to present the winners of the Digital Utilities awards.

Digital Utilities 2022 will dive deep into some of the critical challenges and focus areas for the sector, and provide delegates with genuine learning opportunities from some of the best and brightest minds across Australia.

This will be the fourth iteration of the conference and will help delegates keep up-to-date with the latest trends and developments in digitisation.

Attendees will be able to enjoy the entire event from the comfort of their homes or offices, but for those who want to get extra value from meeting up with peers in the real world, there will also be the live networking awards event to make new connections and catch up with like-minded colleagues.

Dates and programs to be announced shortly. Keep an eye on the Utility magazine website and newsletter for updates, or visit www.digitalutilities.com.au for information on previous Digital Utilities events.

SMARTER INSIGHTS BETTER OUTCOMES

Make years of project knowledge work for you by leveraging key insights. You’ll improve outcomes with better scope, cost and schedule certainty.

UTILITY • FEBRUARY 2022 WWW.UTILITYMAGAZINE.COM.AU 10 NEWS PROVEN PROJECT CERTAINTY

INEIGHT.COM 20211201_ADV_H221_Collage_Male2_SmarterInsights_185x125_v1.indd 1 12/1/21 9:08 AM

2022

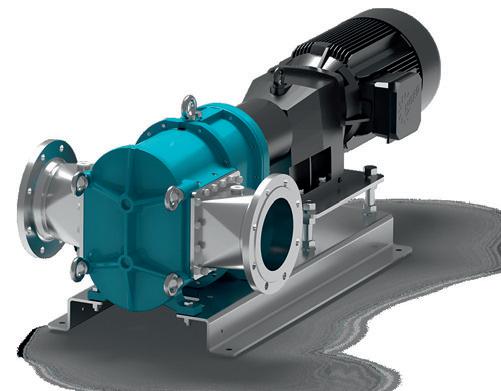

EXCELLENCE – MADE TO LAST

WE DELIVER SOLUTIONS

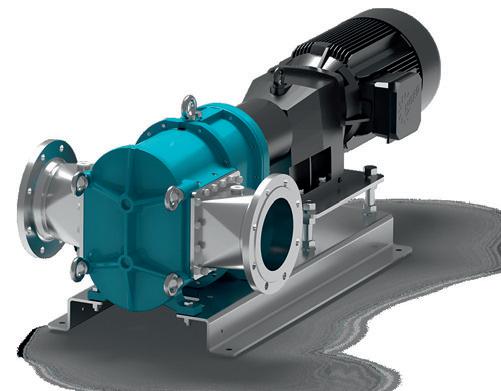

Mobile, stationary or submerged – Börger configures and builds each rotary lobe pump in line with the requirements of the specific application.

The application options of Börger pumps have expanded with the new B BLUEline Nova rotary lobe pump. The BLUEline Nova pump ensures the best efficiency even with high pressures. Börger pumps are available in 25 pump sizes with flow rates between 1 – 1,440 m³/h.

THE MOST EFFICENT WAY OF PUMPING

Further to this, Börger also offers three different macerators - providing efficient chopping operations and capabilities, ensuring downstream machines and pumps to perform smoothly.

www.boerger.com Boerger Pumps Asia Pte Ltd • 16 Boon Lay Way #01–48 Tradehub 21 • Singapore 609965 • P: +65 6562 9540 • asia@boerger.com

SEWER UPGRADE CONTRACT AWARDED

Melbourne Water has awarded a contract to duplicate the Hobsons Bay Main Sewer, which carries over 30 per cent of Melbourne’s wastewater to the Western Treatment Plant, with the $200 million project one of the largest upgrades to Melbourne’s sewer network.

The contract has been awarded to the John Holland Group and is expected to create over 20 jobs.

Victorian Minister for Water, Lisa Neville, said this vital project highlights the State Government’s commitment to delivering essential water

infrastructure to support the city’s growing population.

“This sewer, originally built in the 1960’s and which runs under the Yarra River from Westgate Park in Port Melbourne to Spotswood, is integral to the Melbourne sewerage network,” Ms Neville said.

“This significant investment will ensure the reliability of Melbourne’s sewage service for the next century –and also create local jobs.”

Melbourne Water’s General Manager Major Project Delivery, Eamonn Kelly, has congratulated John Holland Group on being successful after an extensive tender process.

“We’re delighted to announce John Holland Group has been selected as the preferred contractor to carry out this important project as part of our overall upgrade to the Hobsons Bay Main Sewer,” Mr Kelly said.

“Melbourne Water has enjoyed a long-standing relationship with John Holland to deliver a wide range of our projects.

“Once the duplicate sewer is complete it will allow flows to be diverted from the original pipeline.”

Works will begin at Scienceworks in early 2022 and the project is due for completion in 2024.

UTILITY • FEBRUARY 2022 WWW.UTILITYMAGAZINE.COM.AU 12 & Velocity measurement Continuous Biofilm Monitoring Sample Biofilm growth signal over time LEVEL METERS BIOFILM ANALYSER ANALYTICAL CONTROLLERS PROCESS INSTRUMENTS PULSAR • Lightweight, compact design • No interruption to service • ATEX Ex mb Zones 1 & 2 approval • Minimal installation costs • Maintenance-free • RS485 Modbus • IP68 • Non-contacting • Cost-effective • Ultrasonic Transmitters and Controllers • Point Level Switches • Sludge Level Systems • Wireless Systems • Early detection of Bacterial Growth on surfaces • Monitoring & optimisation of sanitation requirements. NEW TURBIDITY MONITOR BINTECH SYSTEMS WATER SOLUTIONS 1300 363 163 sales@bintech.com.au www.bintech.com.au NEWS

$200 MILLION MELBOURNE

Solving for the aftermath. Before the aftermath.

Smart grid technology, intelligent devices and an industrial IoT network to connect it all. Not only is this the best way to prepare your grid for a storm, but it’s the best way to bounce back afterward. Reduce outage minutes, restore service efficiently and recover quickly. We can’t predict the weather. But we can be ready for it.

More intelligence. More possibilities.

Itr on.com/possibilities

© Copyright 2021 Itron. All rights reserved. Itron and the Itron logo are registered trademarks of Itron, Inc.

AGL BREAKS GROUND ON

$180 MILLION BATTERY

AGL has broken ground on its $180 million Torrens Island 250MW battery, preparing for construction of the facility, which will form part of the Torrens Island Energy Hub and support renewables in South Australia.

The Torrens Island battery will be the first of AGL’s national roll-out of 850MW of grid-scale batteries to get underway.

AGL announced in early 2021 that it had appointed technology group, Wartsila, to construct the Torrens Island battery.

South Australian Minister for Energy and Mining, Dan van Holst Pellekaan, welcomed the start of work on the battery and the benefits it will bring to the state’s energy system.

“AGL’s Torrens Island battery has 66 per cent more power and 25 per cent more storage than the now expanded big battery at Hornsdale,” Mr van Holst Pellekaan said.

“This project was assisted by a fast-tracked planning process by the Marshall Government to provide vital grid security benefits and help accelerate South Australia’s transition to net 100 per cent renewable energy generation by 2030.”

AGL expects up to 50 local jobs will be created during construction, and the battery is planned to be fully operational by early 2023.

AGL Chief Operating Officer, Markus Brokhof, said low-emission firming technologies will play a leading role in driving Australia’s energy transition.

“We’re delighted to have the opportunity to commence our battery program in South Australia. This milestone is an important step in bringing to life our vision for the low-carbon industrial energy hubs required for Australia’s energy future,” Mr Brokhof said.

“As Australia’s largest energy generator, we understand the importance of enabling flexibility and ensuring reliability across the National Electricity Market as we continue to integrate renewable generation.”

The battery will enable AGL to adapt to changing market conditions, with an initial one-hour duration that is capable of expanding to up to four-hours in the future.

UTILITY • FEBRUARY 2022 WWW.UTILITYMAGAZINE.COM.AU NEWS P E Level 2, Suite 26/20 Enterprise Drive Bundoora, Vic, 3083 1300 1 L ANCO (52626) tenders@lancogroup com au lancogroup.com.au Your business partner

solutions

1998.

don’t purely just design; we help our customers realize their goal, if you give us an idea we can provide a efficient and effective engineering solution” Accredited consultant with Melbourne Water, Retail Water Corporations – Metropolitan and Regional Areas Corporate Profile Insurance Category Level of Cover $ Professional Indemnity $10 million Public Liability $20 million Work Cover n/a A list of applicable insurances includes: Name of Entity: Lanco Group Pty Ltd ABN: 27 160 328 478 Company Address: University Hill Business Park South Level 2, Suite 26/20 Enterprise Drive Bundoora, Vic, 3083 Company Structure: Private Company Quality ISO 9001 Environment Health & Safety AS 4801 ISO 14001 2

for engineering

Since

“We

OsmoVision

Advanced Structural Resiliency Study

Cost-effectively enhance the resilience of power grid structures with an accurate assessment of existing infrastructure health.

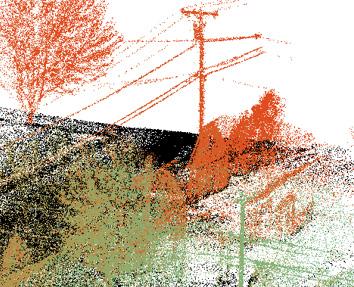

• Generate a digital twin using our proprietary LiDAR point cloud classification and image recognition technology.

• Assess your system resiliency by simulating its ability to withstand high-impact events, such as a cyclone.

• Formulate system hardening solutions that improve your infrastructure’s structural resiliency.

(08) 9300 2950 | enquiries@logsys.com.au | logsys.com.au/osmovision an company

®

TASWATER APPOINTS NEW CEO

TasWater has announced the appointment of George Theo as its new CEO.

Mr Theo is the current Chief Executive Officer of Unitywater in South East Queensland, Australia.

He brings over thirty years of water industry experience to the role, including previous positions at GHD, Brisbane Water (UU) and City West Water in Victoria.

TasWater Board Chairman, Dr Stephen Gumley, said Mr Theo has a proven track record in delivering sustainable outcomes for the benefit of customers, the environment, employees and stakeholders by delivering initiatives that challenge the status quo.

“George has overseen transformation in the way businesses approach productivity improvements, capital planning and delivery, asset management, digital solutions, pricing, community and customer outcomes,” Dr Gumley said.

He is also the current Chairman of SWAN Asia Pacific Alliance, a not-for-profit organisation that brings together key players in the water industry across the region, with a focus on research, technology and digital transformation.

Mr Theo has a Master’s in Business Administration, a Degree in Engineering (civil) and an Associated Diploma in Municipal Engineering.

He is also a Fellow of the Institute of Engineers Australia and a Fellow of the Australian Institute of Company Directors.

“George’s appointment comes after a rigorous recruitment process facilitated by Davidson Search and Advisory, and we are pleased he will be taking up the reins here at TasWater on 14 March 2022,” Dr Gumley said.

Mr Theo is taking over from outgoing TasWater CEO, Mike Brewster, who is retiring.

FLOW, LEVEL , PUMP CONTROL VOLUME , & SLUDGE BLANKET

• Contacting & non-contacting measurement options

• Full, partially filled pipes, and open channel flow measurement

• Ultrasonic and radar technology

• Process measurement made simple

• Customer-centric

• Award winning service

For Australian sales & technical support, contact our local team or use our virtual Partner Locator to find the nearest Pulsar Authorized Distribution Partner

UTILITY • FEBRUARY 2022 WWW.UTILITYMAGAZINE.COM.AU 16 NEWS

Excellence in flow & level measurement.

OCEANIA@PULSARMEASUREMENT.COM +61 ( 0 ) 428 692 274

PROVIDING SECUIRTYPROVIDING SECURITY

Steel Mains is proud to be Australia’s largest manufacturer of Mild Steel pipes for the water industry. We continue to manufacture Sintakote® Steel pipe with manufacturing facilities located in both Victoria and Western Australia. Materials and labour required to manufacture our pipes are sourced locally, ensuring our pipes enjoy greater than 98% local content.

Local stock, delivery and design & installation support mean that Steel Mains is able to reduce all your pipeline supply risks. Local manufacture and product Standardsmark certification provide you with that additional supply security, with all aspects of our manufacturing meeting Australian quality standards. When the lifespan and security of your asset are important to you, Steel Mains Sintakote pipeline systems are your ideal choice for your next pipeline project.

ENERGY NETWORK AUSTRALIA AWARD WINNERS ANNOUNCED

The recipients of Energy Network Australia’s (ENA) Industry Innovation, Contribution and Consumer Engagement Awards have been announced, highlighting the achievements of Australia’s energy network industry.

Western Power Principal Networks Strategy Engineer, Nigel Wilmot, has been named the 2021 Energy Network Australia Industry Contribution Award winner.

The 2021 Energy Network Consumer Engagement Award was awarded to electricity transmission system operator Powerlink Queensland.

The 2021 Energy Network Industry Innovation Award was awarded to Queensland’s electricity distributors Ergon Energy Network and Energex.

CONTRIBUTION AWARD

Mr Wilmot was recognised for his significant contribution to the energy industry, in particular for driving the development of new Australian technical standards that govern the connection of renewable energy

devices to Australian households and businesses.

ENA Chief Executive Officer, Andrew Dillon, said Mr Wilmot’s work would have a lasting effect on Australia’s energy transition.

“Through Nigel’s foresight, he anticipated the huge growth in solar and battery technology and the need to implement a set of standards to ensure the integrity of Australia’s energy grid was maintained,” Mr Dillon said.

CONSUMER ENGAGEMENT AWARD

Run jointly by ENA and Energy Consumers Australia, the Energy Network Consumer Engagement Award recognises an Australian energy network that demonstrates best practice consumer engagement.

Powerlink Queensland received the award for its consumer engagement approach during its 2023-27 revenue determination process.

Energy Consumers Australia CEO, Lynne Gallagher, said the network’s submission showed

outstanding engagement practice and represented a new high-water mark for customer consultation.

“When networks undertake this kind of work, discrepancies between industry assumptions and the reality of consumer experiences are laid bare.

“A clearer understanding of your customer’s values, expectations and needs leads to better-served consumers and is better business as well.”

INNOVATION AWARD

Ergon Energy Network and Energex are the winners of the Innovation Award for 2021.

The winning project is an Australianfirst implementation of a digital system to generate a complete and consistent picture of the operational state of the grid.

The initiative supports the integration of distributed energy resources (DER) like rooftop solar PV, so more customers can export solar, voltage impacts on the grid can be mitigated and power quality can be improved.

18 UTILITY • FEBRUARY 2022 WWW.UTILITYMAGAZINE.COM.AU

NEWS 1800 816 830 enviroline.net.au

Talk to the experts! For all your drain maintenance equipment needs

THE WATER JETTING SPECIALISTS

Digitise your network for a more sustainable water future. ™

Gain real-time visbility of your water and wastewater networks with the NEW Captis Version 1.2. Your complete IoT monitoring and measurement solution - device, cloud, connectivity.

1800 646 828 | miot.com.au

WATER APPOINTS NEW MANAGING DIRECTOR

Melbourne Water has announced the appointment of its new Managing Director, who is the first woman to ever be in the role.

The Board of Melbourne Water revealed Dr Nerina Di Lorenzo as the next Managing Director of the company.

Dr Di Lorenzo succeeds Michael Wandmaker who has been Melbourne Water’s Managing Director since September 2014 and stepped down from the role on 30 November 2021.

Melbourne Water’s Chair, Professor John Thwaites, said Dr Di Lorenzo was an outstanding appointment and the Board was looking forward to working closely with her in the next phase of Melbourne Water’s history.

Dr Di Lorenzo joined Melbourne Water in July 2019 as the Executive General Manager of Service Delivery, helping reshape the organisation to provide reliable and secure water services.

Prior to this role, Dr Di Lorenzo was the Chief Executive Officer of the City of Moreland.

“In her time at Melbourne Water, the Board has been thoroughly impressed by Dr Di Lorenzo’s leadership, skills and ability to drive customer outcomes in a collaborative way,” Mr Thwaites said.

“This historic appointment – the first female Managing Director in the organisation’s 130-year history – builds on previous appointments of women to senior roles in the organisation.”

Dr Di Lorenzo said she was honoured to be appointed as Melbourne Water’s next Managing Director and was looking forward to taking on the role.

“I’m particularly excited about forging stronger relationships with our customers and delivery partners, especially Traditional Owners,” Dr Di Lorenzo said.

“The sector is facing big challenges including long-term water security, reducing our greenhouse gas emissions, improving the health of our rivers and catchments and making greater Melbourne an even better place to live. We can only meet these challenges by working hand in hand with our customers and the community.”

UTILITY • FEBRUARY 2022 WWW.UTILITYMAGAZINE.COM.AU 20

NEWS Unit 2 / 85 Heatherdale Road, Ringwood Vic 3134 PO Box 2500, North Ringwood Vic 3134 P: (03) 9872 4596 | F: (03) 9872 3293 | E: info@pezztrenchless.com.au Still the market leaders in laser guided microtunnelling Bore diameters from 325mm up to 2800mm Used for gravity sewers, water mains, storm water, gas and electrical conduits. Specialists in “free bore”, sleeve boring and pipe jacking in all sizes The Next Generation in Trenchless Technology

MELBOURNE

SEAL CRITICAL PIPE PENETRATIONS

If you have a pipe passing

through a wall, ceiling or floor and need a solution to seal the annular space, Link-Seal might be the answer you are looking for.

Link-Seal is an engineered product, manufactured in the US and available in Australia through Projex Group. It is used extensively in hospitals, oil farms, commercial developments, mines, water and waste treatment plants, and more.

Link-Seals offer hundreds of solutions to seal pipe penetrations ranging in size from 10mm to 3.6m diameter, and can seal against oils, gas, water, aggressive chemicals and fire. Link-Seals are suitable for PVC, HDPE, copper and steel pipes and will produce an immediate seal once installed around the centred pipe and the substrate it passes through. Projex Group offer free technical consultation and will help you calculate the right Link-Seal size and model for your application. To find out which Link-Seal you need, simply email the answers to the following questions at mail@projex.com.au:

For

1. What is the inside diameter of the hole?

2. What is the outside diameter of the pipe?

3. What are you sealing against?

4. What type of pipe are you using?

Projex Group’s job is to specify and guide you as to which product is suitable for your specific application to ensure the complete solution is achieved.

VICTORIA INVESTS $40 MILLION

IN OFFSHORE WIND PROJECTS

The Victorian Government has announced a $40 million funding boost for offshore wind projects, kickstarting three major projects across the state and potentially creating 5,600 jobs.

As part of the Energy Innovation Fund, the Victorian Government is funding three major offshore wind projects – from Star of the South, Macquarie Group and Flotation Energy – bringing $18 billion in investment to Victoria and powering around 3.6 million homes.

The funding boost will support feasibility studies and pre-construction development, including environmental assessments.

• The Star of the South will receive $19.5 million to support pre-construction development activities for an offshore wind farm off the Gippsland coast. If built to its proposed scale, it would have up to 2.2GW of capacity –enough power to provide nearly 20 per cent of Victoria’s energy needs

• Macquarie Group will receive $16.1 million to facilitate initial development stages of a 1GW offshore wind farm off the Bass Coast

• Flotation Energy will receive $2.3 million for scoping studies and surveys for a 1.5GW offshore wind farm off the coast of Gippsland

The funding will help each company conduct studies to determine the exact location of each project, with all major projects requiring a rigorous community consultation process, and subject to a range of regulatory approvals including environmental impact assessments.

Victorian Premier, Daniel Andrews, said, “Victoria is the clean energy capital of Australia – we’ve led the way on renewables, created 24,000 jobs with our VRET target alone, supported a thriving supply chain of businesses and attracted billions in investment.

“Offshore wind is the next step to create thousands of high-skilled jobs, and we know we’re ready with a highly skilled workforce able to step into them.”

Wild winds off Victoria’s coastline, which are among the best in Australia and the world, could help the state reach its target of 50 per cent renewable energy by 2030.

22 UTILITY • FEBRUARY 2022 WWW.UTILITYMAGAZINE.COM.AU NEWS | Sponsored editorial

more information, please visit www.projex.com.au.

CONTRACT AWARDED FOR MT KYNOCH WATER TREATMENT PLANT UPGRADE

Toowoomba Regional Council (TRC) has awarded the contract to complete the Mount Kynoch Water Treatment Plant upgrade, after an extensive tendering phase.

The contract has been awarded to Fulton Hogan Utilities, who will upgrade the Mount Kynoch Water Treatment Plant to help improve water security and service reliability for the region.

TRC Water and Waste Committee Chair, Cr Rebecca Vonhoff, said, “Built almost 50 years ago, the water treatment plant is aging infrastructure that needs work to ensure reliability of service and redundancy in the event of a system failure.

“We also know the treatment plant is almost running at peak capacity so it’s crucial we begin an immediate upgrade

to ensure Council can continue to service the water supply needs of the community as we continue to grow our region.”

The Mt Kynoch Water Treatment Plant sources water from Cooby Dam, Cressbrook Dam and Perseverance Dam. To ensure continuous supply of raw water into the treatment plant, Council must provide a reliable network of pipes, pumps and valves.

Ms Vonhoff said Council will invest close to $28 million at Mt Kynoch over the next three financial years.

In addition to upgrading existing infrastructure, Council is undertaking the design of a new duplicate main that will include a new valve house and delivery main.

The trunk raw water lines from Cressbrook and Perseverance dams interconnect prior to the treatment plant inlet, at the valve house within the Mt Kynoch Park.

There is currently only one incoming main from the valve house into the treatment plant, transporting combined Perseverance and Cressbrook raw water – so this needs to be addressed.

The enhancement works provide improved reliability of incoming water to the plant, with the option of two mains.

“This is a major investment to provide residents with a safe and reliable drinking water supply and is essential for the future growth of the Toowoomba Region,” Ms Vonhoff said.

The project is currently scheduled for completion in late 2023.

UTILITY • FEBRUARY 2022 WWW.UTILITYMAGAZINE.COM.AU 23 NEWS INSTRUMENTATION & CALIBRATION PTY LTD SPECIALISTS AMS have been suppliers of instrumentation and calibration equipment to all industries since 1973 representing some of the world’s leading manufacturers of the equipment in their field. www.ams-ic.com.au Flow Measurement Specialists www.ams-ic.com.au sales@ams-ic.com.au

ADVANTAGES OF ELECTRONIC KEY CABINET INTEGRATIONS

Key holders don’t want to be overwhelmed with several systems. That is why introducing electronic key cabinets with integration to security or human resource systems is very beneficial.

To prevent being disappointed with unrealistic integration promises, it is wise to be apprehensive when told that a reliable key management system third-party API can be built on-the-fly, without foreseeing the time involved in effectively testing it.

Harcor’s IKLAS already has high-level interfaces to many popular third-party platforms. This easily prevents duplication of data entry, card holders and access control groups, and is achieved via sending real-time transactions to the various platforms.

Some common configuration options include antitailgating, which prevents cardholders from exiting the facility if a key has not been returned to the electronic key cabinet. Other advantages of integration include reduced administrative time, data accuracy, comprehensive reporting, more efficient control and ease of maintenance.

INTEGRATING KEY MANAGEMENT SYSTEMS

If high-level integration is not a requirement, the IKLAS LITE could be precisely what is needed. This super costeffective electronic key cabinet includes some features normally only coupled with high-tech electronic key cabinets, like its big brother the IKLAS-ELITE. The cabinet includes an industrial grade touch screen and many other essential key management attributes.

Deciding what systems to use regarding key management can be complex. That is why Harcor is always looking for better ways to integrate key management systems within the current business environment. From high-level configurations to simple access card integration, Harcor is ready to help you.

UTILITY • FEBRUARY 2022 WWW.UTILITYMAGAZINE.COM.AU 24

No. 407319937 Key management Meter security seals Contact us for more information about our comprehensive range of key cabinets. Trackable Serial Numbering Expose Unauthorised Access For more information, please visit harcor.com.au/collections/key-management-system or email sales@harcor.com.au. NEWS | Sponsored editorial

Easy transportation Simple implementation Operator and equipment safety 1300 FMT FMT (368 368) Melbourne 1/53-57 Rimfire Drive Hallam VIC 3803 Brisbane 2/5 Percy Drive Brendale QLD 4500 Perth 3/48 Hardey Road Belmont WA 6104 The water supply operator’s kit H2O WATER KIT

DELIVERING RELIABLE AND ACCURATE

NATURAL GAS SUPPLY

Natural gas production in the United States has been steadily increasing for almost a decade – made possible by oil and gas companies that extract valuable hydrocarbons trapped deep underground.

In natural gas production, a well is sunk and made ready for production, and companies like Blue Racer Midstream process the unfiltered natural gas flowing from the well into products for refineries.

The VEGAPULS 64 supports this process, delivering reliable and accurate measurement data despite the poor reflective properties of liquid gas.

Oil and gas companies are strictly regulated, with redundant measurements required by law for many processes and applications to minimise the risks of tank leakage.

Blue Racer Midstream operates a number of natural gas treatment and processing facilities in eastern Ohio and West Virginia, and supplies a wide range of products that meet the specifications for pipelines.

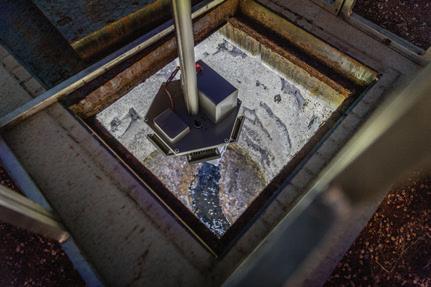

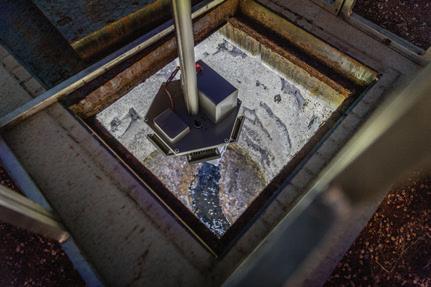

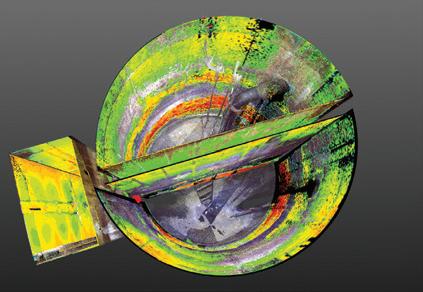

NON-CONTACT MEASUREMENT MADE POSSIBLE

Before purified products make their way through the pipeline, they are stored in large underground tanks. These tanks have access pipes protruding about 30-60cm out of the ground, and at the top of these narrow pipes VEGAPULS 64 radar sensors are installed.

VEGAPULS 64 is a radar level sensor that measures contactlessly with a very high signal frequency: 80 GHz, which allows for a more focused signal.

The sensor can also measure through very narrow openings, as is the case with the access pipes.

Since the majority of the radar beam’s energy is focused on a smaller area, the antenna receives a stronger reflected signal from the product surface.

The 80-GHz radar sensors are repeatedly setting new standards in detecting small, weak signals, due to their dynamic range – especially when measuring hydrocarbons.

VEGAPULS 64 can detect all media in the petrochemical industry, from crude oil to liquid gas, with high reliability.

AN EASY SOLUTION TO A DIFFICULT TASK

Blue Racer Midstream used guided wave radar technology for all level measurements in the two underground storage tanks, two sensors were mounted on each tank – one for continuous level measurement and one for a max. alarm, which shuts down the process to avoid overfilling.

The guided wave radar sensors used in the storage tanks delivered correct level values despite high mounting sockets and bad reflective properties of natural gases.

When the time came to replace the max. alarm sensors on each tank, VEGA suggested using contactless measurement with VEGAPULS 64.

The strong focusing and exceptional sensitivity of the sensor ensures an accurate and reliable level measurement.

80-GHz has a positive effect when measuring liquids with small dielectric constants at the bottom of a vessel.

The result is that even the lowest filling levels can still be measured reliably and accurately.

MORE DEPENDABLE RESULTS

Blue Racer Midstream chose the new VEGAPULS 64 sensors and was impressed with the results.

As each tank requires two sensors for the same measurement, operators were able to directly compare the performance of the new non-contact radar sensors with that of the original sensors.

In this comparison, the accuracy of VEGA technology was totally convincing, and as a result, Blue Racer Midstream began replacing the guided wave radar instruments with new VEGAPULS 64 radar sensors in all locations.

UTILITY • FEBRUARY 2022 WWW.UTILITYMAGAZINE.COM.AU 26

NEWS | Sponsored editorial

VEGAPULS 64 IS USED IN NUMEROUS PLACES THROUGHOUT REFINERIES

Controller and display instruments for 4… 20 mA level sensors

Controller and display instruments for 4… 20 mA level sensors

Compact controller and display instrument for level sensors

VEGAMET 141/142

carrier rail mounting switching cabinet

carrier rail mounting switching cabinet

carrier rail mounting switching cabinet

front panel mounting built-in wall/pipe mounting

front panel mounting built-in wall/pipe mounting outdoors

front panel mounting built-in wall/pipe mounting outdoors

www.vega.com

www.vega.com

www.vega.com

▪ Complex programming of control tasks is no longer necessary

Compact controller and display instrument for level sensors

Controller and display instruments for 4… 20 mA level sensors

VEGAMET 141/142

▪ Simple and safe setup and diagnosis of measuring points via smartphone

▪ Easy control of the measuring point by graphic display, even in the dark

▪ Complex programming of control tasks is no longer necessary

Compact controller and display instrument for level sensors

▪ Simple and safe setup and diagnosis of measuring points via smartphone

VEGAMET 141/142

▪ Easy control of the measuring point by graphic display, even in the dark

▪ Complex programming of control tasks is no longer necessary

Built-in controller and display instrument for level sensors

▪ Simple and safe setup and diagnosis of measuring points via smartphone

VEGAMET 341/342

▪ Easy control of the measuring point by graphic display, even in the dark

Built-in controller and display instrument for level sensors

▪ Complex programming of control tasks is no longer necessary

VEGAMET 341/342

▪ Simple and safe setup and diagnosis of measuring points via smartphone

▪ Easy-to-read display from a distance, even in sunlight and darkness

▪ Complex programming of control tasks is no longer necessary

Built-in controller and display instrument for level sensors

▪ Simple and safe setup and diagnosis of measuring points via smartphone

VEGAMET 341/342

▪ Easy-to-read display from a distance, even in sunlight and darkness

▪ Complex programming of control tasks is no longer necessary

Robust controller and display instrument for level sensors

▪ Simple and safe setup and diagnosis of measuring points via smartphone

VEGAMET 841

▪ Easy-to-read display from a distance, even in sunlight and darkness

Robust controller and display instrument for level sensors

VEGAMET 841

▪ Clearly arranged, readable from a distance and individually programmable display

▪ Complex programming of control tasks is no longer necessary

▪ Clearly arranged, readable from a distance and individually programmable display

Robust controller and display instrument for level sensors

▪ Easy-to-read display from a distance, even in sunlight and darkness

VEGAMET 841

▪ Complex programming of control tasks is no longer necessary

▪ Easy-to-read display from a distance, even in sunlight and darkness

▪ Clearly arranged, readable from a distance and individually programmable display

▪ Complex programming of control tasks is no longer necessary

▪ Easy-to-read display from a distance, even in sunlight and darkness

USING THERMAL ZINC DIFFUSION COATING TO EXTEND PART LIFE

Finding the right galvanising method is critical to prolonging part life, especially in harsh mining, construction, and marine environments.

ArmorGalv® Australia is the first plant of its kind in this country, boasting a corrosion resistant and abrasion resistant coating solution that helps increase part life – making this technology a must-have for those in the utility products, infrastructure, energy, construction, mining, oil and gas industries.

The advanced ArmorGalv® coating technology is called thermal zinc diffusion galvanising, which is a uniform, sacrificial, zinc-iron coating, applied to any ferrous item using a metallurgical vapour diffusion process.

In contrast to other galvanising methods, thermal zinc diffusion galvanising does not leave any areas of the product ungalvanised; this is because the formation of a zinc coating by means of diffusion is not hampered by the product's geometry.

The ArmorGalv® Thermal Zinc Diffusion coating is a standard finish option for all Ferrous Metal Products and perfect for threaded bar, engineered fasteners, both high tensile and commercial grade.

REVOLUTIONISING THE INDUSTRIAL METAL PRODUCTS MARKET

Becoming known as Galvanising 2.0, this uniform deposition coating is poised to revolutionise the industrial metal products and fastener market, with over 1,000 hours of corrosion resistance, no risk of hydrogen embrittlement, and no insignificant surfaces.

Traditionally, fasteners were coated to provide them with corrosion resistance and proper torque tension (coefficient of friction) characteristics, while trying to avoid inducing them with the catastrophic effects of hydrogen embrittlement.

Today, there is the added requirement and challenge, that the process of coating the fasteners be environmentally friendly, and that the resulting coating itself be nontoxic and chrome free.

Recently, major advances have also been made in thermal zinc diffusion technology to improve its efficiency and reproducibility.

IS THERE A SPECIFICATION COVERING ARMORGALV ® COATING?

The ArmorGalv® coating is covered by the Standards ASTM 1059 A / M and ISO 17668.

Coating classes range from 20-120 microns, defining the target coating thickness.

For the most common coating thickness of 50 micron, thickness variance is typically between 45-60 microns.

WILL THERMAL ZINC DIFFUSION REPLACE CADMIUM FOR ANTI-GALLING?

The main benefits of cadmium, which due to safety concerns has been banned virtually worldwide, were its anti-galling properties, and its ability to not ‘seize’ in the presence of its own corrosion products due to its inherent lubricity properties.

Due to increased hardness and wear resistant properties, thermal zinc diffusion provides good anti-galling properties, predominantly facilitated by the absence of free zinc at the outer surface.

WILL TOPCOATS ADHERE TO ARMORGALV ® ?

ArmorGalv® is not pure zinc, it's layers (phases) of zinc/ iron alloy, meaning the surface is not smooth like that of bright electroplated zinc, and that it has superior adhesion of powder coat, paint, rubber, silicates, or Xylan.

HOW ENVIRONMENTALLY FRIENDLY IS ARMORGALV®?

The ArmorGalv® Thermal Diffusion process generates practically zero landfill material and results in a chrome-free nontoxic coating.

In 2006, the US Environmental Protection Agency awarded the ArmorGalv® process its prestigious MVP2 Award – The most valuable new technology award. For further technical information, please go to: www.armorgalv.com.au

UTILITY • FEBRUARY 2022 WWW.UTILITYMAGAZINE.COM.AU 28 NEWS | Sponsored editorial

A R M O R G A L V P R O T E C T I O N

F O R A L L F E R R O U S M E T A L S

H i g h l y c o r r o s i o n a n d a b r a s i o n r e s i s t a n t

C o n t r o l l a b l e , e v e n a n d p r e c i s e – f r o m

2 0 μ t o 1 0 0 μ p l u s

H a r d , n o n - m a g n e t i c , w e l d a b l e a n d s p a r k

f r e e

C h i p p r o o f a n d a m e n a b l e t o c r i m p i n g , b e n d i n g a n d f o r m i n g p o s t p r o c e s s

N o h y d r o g e n e m b r i t t l e m e n t

GRADES 8.8, 10.9, 12.9 & THREADED BAR

NO HYDROGEN EMBRITTLEMENT

ANTI-GALLING

LOW CO-EFFICIENT OF FRICTION

TORQUE TENSION TESTED

NO LOSS OF HARDNESS OR TENSILE STRENGTH

F o r P e r f o r m a n c e

a n d E n d u r a n c eA r m o r G a l v i t !

H i g h l y h e a t r e s i s t a n t ( u p t o 6 5 0 ° C )

E x c e l l e n t s u b s t r a t e f o r p a i n t , e p o x y ,

r u b b e r o r p l a s t i c

0

a l l y

S T E N E R

T U

T o x i c a l F r e e A S A

C

S :

2

0 2

4

7 6 0

a l e s @ a r m o r g a l v . c o m . a u

w w . a r m o r g a l v . c o m . a u

8 6

s

w

Strong, Reliable Corrosion Protection for Hi-Tensile Threads

A S K U S F O R Y O U R G A L V A N I S I N G 2 . 0 I N F O R M A T I O N P A C K

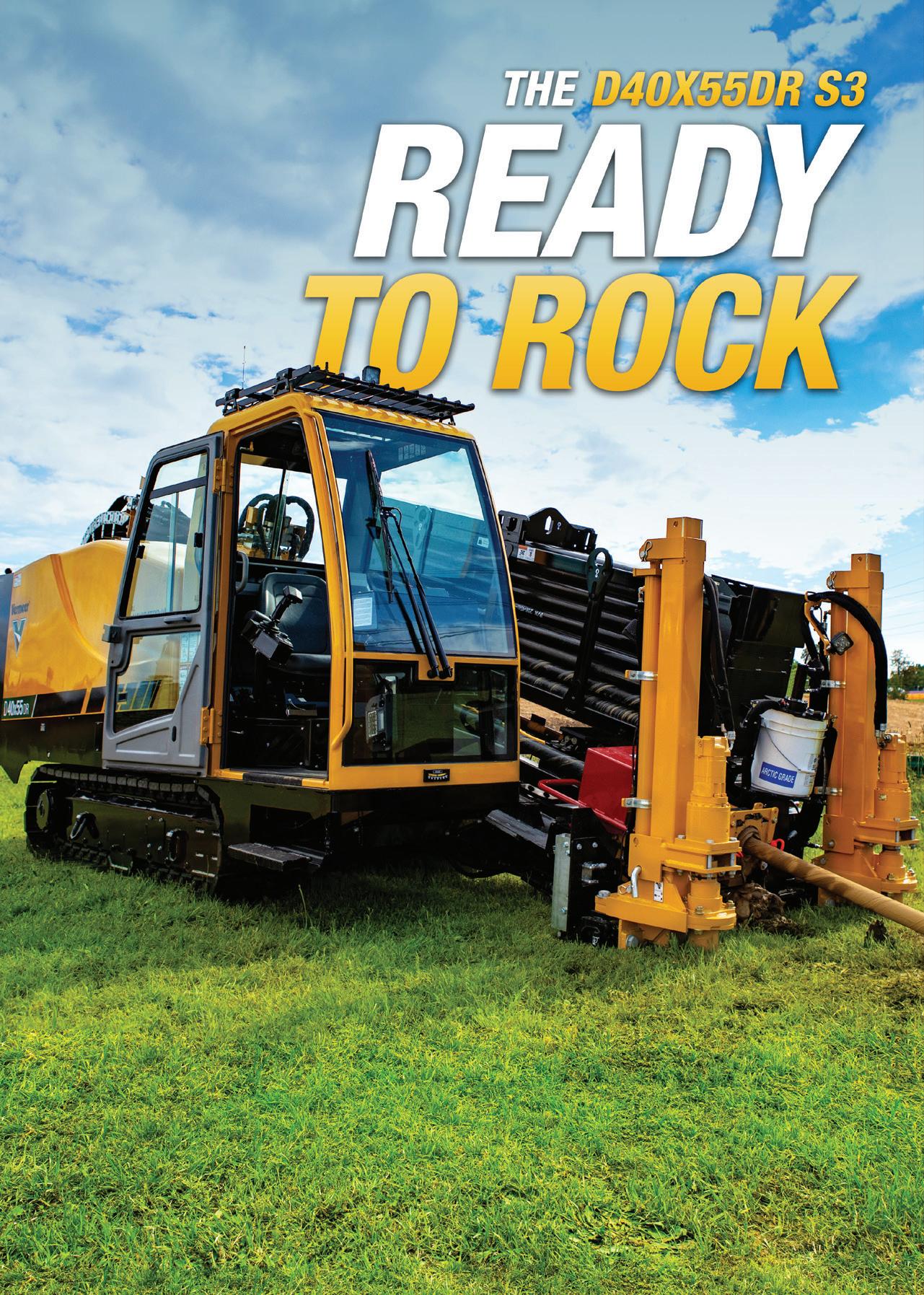

ON MAJOR PROJECTS USING HDD MAXI-RIGS

There is increasing awareness across the utility industry that horizontal directional drilling (HDD) can provide an effective whole-of-life solution for the installation of pipelines. In this article, Maxibor CEO and Owner, Rodney O’Meley, provides insights into maxi-rig spreads and highlights the benefits of utilities and other infrastructure asset owners using HDD maxi-rigs on major projects.

Maxi-rigs are defined as those HDD rigs required for the installation of pipelines between 400mm (16 inches) and 1200mm (48 inches) in diameter, and rated for more than 45,359kg (100,000lb) of thrust and greater than 9,072kg (20,000lb) of torque. Maxibor has four maxi-rigs – a Vermeer 330x500, American Auger 660, Gallagher 600 and Gallagher 660e, and access to others if required.

The maxi-rig spread is a significant investment, as it comprises much more than just the rig. Drill fluid cleaners, high volume pump(s), mud mixer, vacuum truck, rods and tooling and excavators to manage the pipe and rods, all add to the on-site cost of the spread even before a rod is turned. The purchase cost of a new spread today would not leave much change from AUD$8 million.

The mobilisation, demobilisation and on-site relocation also requires having prime movers, trailers and sideloaders to move the equipment. A good on-site stock of spare parts, extra rods and tooling are all essential if you want to maintain productivity on major projects, especially in more remote locations, not just ‘nice to haves’.

INVOLVEMENT FROM THE EARLY STAGES

The length and diameter of pipelines that maxi-rigs can install will depend on the ground conditions and pipe being installed. While they have the capacity to drill pipelines in excess of 2km with diameters up to 1.6m, typically in Australia maxi-rigs are mostly used on projects in excess of 500m with bore diameters of more than 600mm.

Involvement of maxi-rigs on smaller projects can be seen as a reflection that the Australian infrastructure sector has traditionally taken a conservative approach to the use of HDD and other trenchless technology installation methods. The industry has only just reached its 30th year in Australia, whereas the US recently celebrated 50 years and is regularly doing bores over 4km with maxi-rigs.

However, the knowledge and capacity to take on more challenging projects in Australia is certainly there, particularly where you have very experienced design and construct HDD providers like Maxibor.

This enables the integrated body of knowledge required to deliver more complex HDD projects to be involved from early design through to delivery and final commissioning and testing of the pipeline. Maxibor is now regularly being sought out to be involved in the concept stage of projects. Decision makers and other stakeholders are then better informed about the construct options and value-add solutions to project challenges using HDD.

PROVEN IN THE FIELD

Maxi-rigs are ideally suited for river crossings, ocean outfalls, hard rock conditions and multiple service bores requiring larger diameter holes. Distance is not a problem, nor is force, to complete the bore, as the power of the maxi-rigs and the pumps (e.g. Gardner Denver PZ9s) are more than sufficient to overcome the most difficult ground conditions, bore length or other design constraints.

Projects where Maxibor has used its maxi-rigs have included a 1.320km Logan City Council project which connected the Greater Flagstone Priority Development Area with the Cedar Grove sewerage treatment plant. Maxibor designed and delivered a 1.320km bore installing 500mm of PE100 HSCR PN20 to a depth of over 50m. This is still one of the longest bores in Australia in recent years.

The advantage of having maxi-rigs in the fleet was demonstrated on a project to install a new 400m section of water pipeline between Lamb and Macleay Islands in Queensland. Maxibor used one of its Vermeer 100x120s to complete the pilot hole and most of the reaming. The Vermeer 330x500 maxi-rig was then brought in to use its extra muscle to ream the bore hole to a 550mm diameter and pull the DN400 PN20 pipe through.

Into 2022, Maxibor has several bores lined up for its maxi-rigs with distances in the 1.5km to 2.5km range. It is also working in the early design stage with various asset owners and principal contractors on other projects across Australia where its ability to solve complex river and harbour crossings and outfall project challenges will help optimise outcomes for all stakeholders.

UTILITY • FEBRUARY 2022 WWW.UTILITYMAGAZINE.COM.AU 30

NEWS | Sponsored editorial

THE HULK - A GALLAGHER HDD660E ELECTRIC MAXI-RIG.

INCREASING INFRASTRUCTURE ASSET RESILIENCE

The main benefit of maxi-rigs is that they have the ability to provide solutions to challenging infrastructure installation problems. Maxi-rigs will quickly come to the fore in the current decade as climate change mitigation measures need to be put in place as protections against the impact of severe climate events. Electricity, telecommunications, water, sewerage and gas assets will be increasingly impacted by wind, fire, flood, erosion, drought and inundation.

Many of these assets are also vulnerable because of their age, and above ground replacement or trenching

is no longer a medium-term viable option. As Maxibor has highlighted in previous articles in Utility magazine, infrastructure asset resilience will be a key challenge as asset owners confront climate change. Australia really needs to be going ‘down under’ and use HDD maxi-rigs to install its infrastructure assets!

With the ever-increasing congestion of utility services in metropolitan areas of Australia, the difficulty of installing new infrastructure is increasing. The trenchless solution of having longer and deeper runs overcomes the services location (and missing) issue. Maxi-rigs are an ideal solution for new infrastructure assets such as data lines, charging stations and green hydrogen, where there is a point A to point B objective rather than with a myriad of connection points, like there was with the NBN roll out.

An exciting recent addition to the Maxibor fleet has been its electrified Gallagher HDD660e maxi-rig (The Hulk). The electrified spread comes with its own substation which also connects to two powerful Gardner Denver PZ9 pumps and a large Gallagher mud recycling system.

The Hulk is capable of drilling over 3.5km in a single shot with a diameter up to 1.6m. Electric spreads are the direction of the future for the HDD industry as it responds to the need for emissions and noise reduction. Maxibor is excited to be leading the way in this space in Australia.

UTILITY • FEBRUARY 2022 WWW.UTILITYMAGAZINE.COM.AU 31

Sponsored editorial | NEWS AUSTRALIA’S LEADING HDD SPECIALIST Maxibor is using its design and construct expertise to deliver better project outcomes to asset owners and principal contractors alike 02 4966 5583 www.maxibor.com.au admin@maxibor.com.au Follow us on LinkedIn, Facebook & Twitter

and collaborative

and construct services

to advise at the right

project delivery cycle

water and sewer, rail, road,

and

capable

a

For more information, please visit www.maxibor.com.au or contact David Turner on 0499 375 511.

»Quality

HDD design

»Expertise

time in the

»Gas,

power, telecommunications, mining, residential development, renewables

hydrogen »Maxi-rigs

of long and wide diameter bores in hard rock and difficult conditions »Build

future we all look forward to.

VERMEER 330X500 AT LAMB ISLAND.

BIG DATA SUPPORTING THE NEW ENERGY PARADIGM

by Ruchika Deora, Program Director, The Centre for New Energy Technologies (C4NET)

Australia’s transition to a new energy future will not be a smooth one without a massive shift in operational and market management.

The rapid uptake of hyperlocalised, consumer driven technologies is upon us. Current solar, heating and cooling, electric vehicle (EV) and storage trends, collectively known as Distributed Energy Resources (DER), require systematic management to ensure we maintain a cost-efficient, secure and reliable electricity supply that also supports our environmental objectives.

But the path to successfully integrating and accommodating these DER is littered with political hurdles, conjecture and technical and regulatory complexity. Traditional power system planning and assessment tools must evolve to better serve customer and market requirements. This means industry requires new ways to ensure network and market stability.

Thankfully, the recent democratisation of multiple data streams means that the opportunities to use detailed analysis to inform our system planning do exist. However, access to reliable electricity consumption data will be key to ensuring that evidence-based decision making will guide the entire sector into our new energy paradigm.

DATA ACCESS SERVICES

The Centre for New Energy Technologies (C4NET) has access to this energy consumption data as well as the experts to be able to model

this data to provide useful insights to any interested party. Its Data Access Services now allow any interested group to request its aggregated data.

As a first step, we need to utilise all available evidence and data at hand to forge our pathway forward. These two terms are often used interchangeably but there is a difference and it is important to understand the nuance between the two.

The former is the narrative for defining and understanding where we have been and where the sector needs to go; from one-way delivery of electricity to multi-directional power flows. Data on the other hand is the instrument that enables and gives credibility to this narrative. Both are required to advance change in any industry, but for reasons still unknown, we often fall to one or the other, rarely leveraging them together to create a complete pathway for multiple stakeholders to accomplish our objectives.

Big data was originally associated with three key concepts: volume, variety, and velocity, better defined as how much, how many types and how fast. But recently, two arguably more important “Vs” have emerged – value and veracity. Data itself can have intrinsic value, but can be worthless until that value is uncovered and applied. Equally, without veracity – how

truthful is your data and how reliable it is – your data has no value.

In the past, detailed visibility of low voltage systems wasn’t necessary to efficiently manage the secure and cost-effective supply of electricity to consumers. But, as more consumers become generators and exporters of electricity, local power quality maintenance is essential in meeting policy and compliance objectives. Confidence in network performance i.e. voltage management and line impedance, is fundamental for system and market planners to manage bi-directional power flows to meet customer needs.

It would not be a stretch to say that the current system of modelling growth and capacity is not keeping pace with the commercialisation of consumer technologies that influence power system operations. But it does not have to be so.

For instance, AMI meter data can inform what is happening on the network at specific times and locations, from how much electricity load is being exported onto or drawn from feeders and transformers. Other new forms of modelling AMI data can assist in phase grouping of customers, topology estimates, impedance levels of distribution lines and service cables and identification of unmetered loads. This level of visibility enables more uptake of new DER and renewable

UTILITY • FEBRUARY 2022 WWW.UTILITYMAGAZINE.COM.AU 32

BIG DATA

energy based on the capacity and capability of existing assets. It also helps guide infrastructure investment decisions based on real world information. It really underscores that access to detailed data, from the source can and should be used to model, forecast and anticipate system requirements.

PUTTING THE DATA TO WORK

The question of who has access to accurate data can also define how an industry will evolve. Is data freely available such that different parties can create diverse narratives to inform transition? Or are there still barriers, whether perceived or real, to accessing information from various data holders?

In Victoria, we are not only fortunate to have a high penetration of smart meters, but also that the data from these smart meters is available to a variety of stakeholders. As a result, the data has been used to provide rich, rigorous insights on the future of the market and operational and technical requirements to support change in how our grid operates.

Interested parties such as community energy groups clamouring for data can now request their actual

consumption by local government area or post code so that they can better understand commercial and retail options available to them. Achieving greener energy independence is also possible through the assessment of NMI level consumption data.

Others like the state government are using AMI data to inform policy development so that system-wide integration is achieved holistically and with customer, market, network, technology, operational and regulatory objectives in mind. Meanwhile industry and researchers are collaborating on new ways of using data to forecast and model EV penetration, vehicle-to-grid storage solutions, early fault detection, and digital network topology.

The list goes on. All of these examples illustrate the substantial return on investment in big data when you analyse and act on your data.

So move forward on your path towards our new energy future by getting clarity with a visual analysis of varied data sets. Explore the data further to make new discoveries. Share your findings with others. Build data models with machine learning and artificial intelligence. Put the data to work.

As an industry we still need to do more to fully maximise the value of data and how we create the evidence narrative to support change. Working in silos is no longer compatible with an integrated smart grid. The collision of consumers acting as generators, aggregators supporting network and market operations, and rapidly changing policy and regulatory guidelines requires us to work together. Sector needs to invest in understanding how to manage millions of DER using 5 minute settlement techniques to operate a stable network.

It’s a collaborative discovery process that requires insightful analysts, business users, network planners, market operators, government, regulatory bodies, compliance organisations and executives to ask the right questions, recognize patterns, make informed assumptions and forecast behaviour.

Only then will we have a roadmap that not only charts our pathway to our new energy future but creates the cross function and industry buy-in required to execute this future successfully. Data isn’t the solution to the energy transition, but it is the path to the solution.

UTILITY • FEBRUARY 2022 WWW.UTILITYMAGAZINE.COM.AU 33

BIG DATA To find out more about C4NET’s Data Access Services go to https://c4net.com.au/.

COMBATING NETWORK LEAKS with digital technology

For Australian water utilities, non-revenue water is a continuous challenge, with no clear solution at scale. Andrew Forster-Knight, General Manager of Digital Utility at South East Water, discusses how digital solutions are enabling utilities to identify and locate network leaks.

BIG DATA | Sponsored editorial

34

Network leaks have a number of serious consequences for water utilities, including the wastage of a finite resource, loss of revenue, increased maintenance costs, customer disruption and reputational damage.

A 2019 Bureau of Meteorology report estimated nonrevenue water loss, over the past five years, accounts for approximately 10 per cent of Australia’s utilities' water supply.

Andrew Forster-Knight, General Manager Digital Utility at South East Water, said water loss is a major challenge for utilities worldwide.

“While Australian utilities enjoy a relatively low level of nonrevenue water on a global scale, there are huge benefits if we can further reduce even a small percentage of non-revenue water,” Mr Forster-Knight said.

As one of the country’s biggest water suppliers and wastewater managers, South East Water delivers more than 136 billion litres of drinking water and collects over 108 billion litres of wastewater each year in Melbourne’s south-east.

IDENTIFYING THE LOCATION OF LEAKS