IRRIGATION INNOVATION: PUTTING WATER BACK IN THE MURRAY MAKING METERING SMARTER ON DIGITAL UTILITIES KEVIN HUTCHINGS

WATER | SEWER | ELECTRICITY | GAS | NBN Engineering, Construction & Maintenance www.utilitymagazine.com.au Issue #10, May 2016

WITH SPATIAL SURVEYING FIGHTING FIRES

Monkey Media Enterprises

ABN: 36 426 734 954

PO Box 3121

Ivanhoe North VIC 3079

P: (03) 9440 5721

F: (03) 8456 6720

monkeymedia.com.au

info@monkeymedia.com.au

utilitymagazine.com.au

info@utilitymagazine.com.au

ISSN: 2203-2797

FROM THE EDITOR

Innovation seems to be the word of the moment, ever since late last year, when Prime Minister Malcolm Turnbull unveiled his government’s National Innovation and Science agenda, with a focus on creating a modern, dynamic, 21st century economy for Australia.

Innovation has been a key focus for utilities in recent months as well. Coming off the back of one of the most disruptive years the industry has ever seen, utilities are realising that the answers to the challenges they currently face lie in innovation. With innovation, challenges become opportunities, and the closing of doors leads to the opening of others.

The energy sector faced its share of disruption in 2015, and this will only continue to be the case in 2016 and beyond. Distributed generation options are proving to be more popular, more effective and more efficient than ever before, and recent improvements in battery storage have been the key catalyst for this change. While these changes present a challenge for the energy industry, they also present opportunities. Mark Coughlin, PwC Australia’s energy, utilities and mining leader, argues in this issue that there’s never been a more exciting time to be an Australian energy provider. He also states that the core capabilities for the utility of the future will be an ability to influence the agenda; and to respond quickly to the ever-changing needs of customers.

One of the industry’s biggest champions of these ideals has to be Kevin Hutchings, Managing Director of South East Water in Victoria. Kevin is passionate about the opportunities new technologies, new ways of thinking and

new ways of engaging with customers present utilities, and he is forging a path for South East Water to establish itself as a truly digital utility. It’s been a privilege to gain insights into Kevin’s thoughts and ideas on this topic in this issue, and I hope you enjoy the opinion piece he’s provided as much as we have.

Whether it’s water or energy, there’s one key element that will bring these industries closer to the innovative, digital future we’re striving for, and that’s smart meters. Advanced metering gives utilities the tools to better respond to their customers’ needs, and provide the kind of information customers now expect access to. In this issue, we take a closer look at how the rollout of meters around the country is progressing; and consider some of the reasons why utilities need to act now and take advantage of the benefits this technology can provide. This is the biggest issue of Utility we’ve produced to date; and I’m thrilled that we will be sharing a magazine of this high standard with delegates at a record nine industry events around the country. Through our ongoing partnership with WIOA, this magazine will be distributed at WIOA’s Queensland event in June; and we also have partnerships with the ENA, Irrigation Australia, GITA and the Energy Storage Council which will see this magazine distributed at their events. You’ll also be able to find copies of Utility at OzWater and Australian Energy Week. The Utility team, including myself, will be attending all of these events, and we look forward to seeing as many of you as possible over the coming months.

by ISSUE 10 May 2016 Cover image shows Geomatic Technologies surveying the Powercor AusNet Services network. WATER SEWER ELECTRICITY GAS NBN Engineering, Construction & Maintenance IRRIGATION INNOVATION: PUTTING WATER BACK IN THE MURRAY MAKING METERING SMARTER ON DIGITAL UTILITIES KEVIN HUTCHINGS WITH SPATIAL SURVEYING FIGHTING FIRES

Published

Chris Bland Publisher and Editor Publisher and Editor

Bland Managing Editor

Associate Editors

Goldsmith

Journalist Jessica Dickers Marketing Director

Kennedy

Harbinson

Designer

Creative Director

by

Chris

Laura Harvey

Michelle

Emily Thomas

Amanda

Marketing Consultants Aaron White Jordan

Graphic

Alejandro Molano

Sandy Noke Monkey Media Enterprises ABN: 36 426 734 954 PO Box 3121 Ivanhoe North VIC 3079 P: (03) 9440 5721 F: (03) 8456 6720 monkeymedia.com.au info@monkeymedia.com.au utilitymagazine.com.au info@utilitymagazine.com.au ISSN: 2203-2797 Published

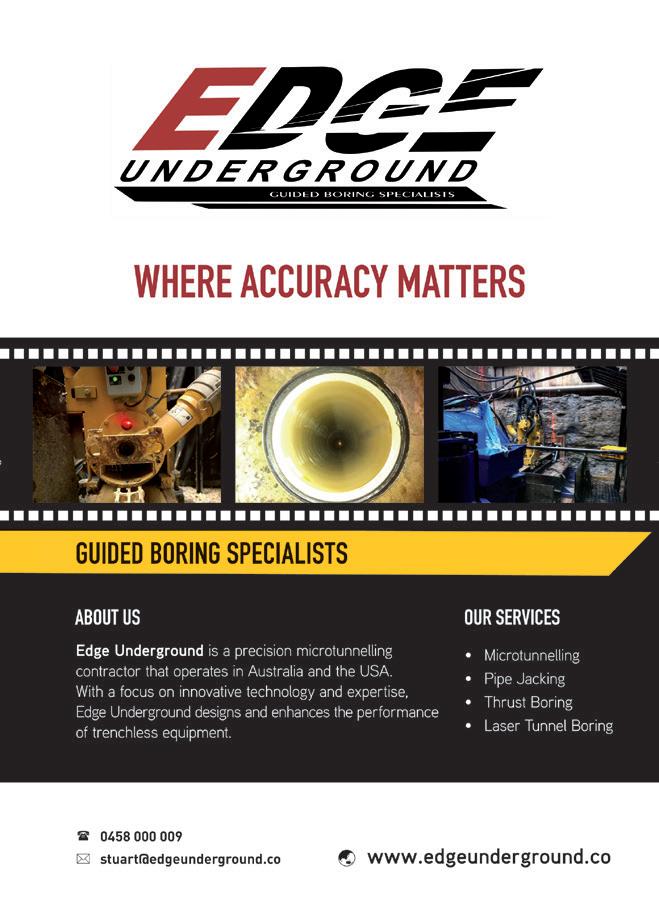

6 CONTENTS 20 30 42 72 82 88 MAPPING, GIS & SURVEYING Managing Victoria’s bushfire risk with spatial surveying 20 The new hub of water utility innovation ................................... 24 Enhancing value and confidence through accurate asset location data .............................................. 26 SMART METERS Plotting a path to digital success ........................................ 30 Making metering smarter .......... 34 How the cloud is helping utilities cope with the smart meter data deluge .......................................... 38 Setting the agenda for smart meters in Australia 40 MICROTUNNELLING Breaking records in long drive microtunnelling........................... 42 Safety from the ground up ........ 44 CONDITION ASSESSMENT How are utilities banding together to manage assets? 88 IRRIGATION Irrigation innovation: putting water back in the Murray ................................... 92 M2M AND MOBILITY Digital utilities: adapting to consumer expectations and operational realities .................... 82 Taking the first step towards smarter mobility: making utility service more reliable 86 i STORAGE EV2G – imminent reality or electric fiction? 72 Energy storage: the path to reaching critical mass ................. 76 DISTRIBUTED GENERATION What will drive the power sector in 2016? ........................................ 78

NBN Ramping up the rollout 96 VEGETATION MANAGEMENT ActewAGL takes flight to inspect its network 100 ISSUE 10 7 46 58 64 WATER Odour control at Gold Coast Water 46 Modelling catchments, managing risk ............................. 48 Reliability, efficiency and superior performance ................................ 52 Increasing the efficiency of our water assets 54 Smart rain: tracking inflow and infiltration .................................... 56 PROJECTS Drilling for a sustainable future ........................................... 58 Smart sewers: revolutionising the way utilities manage wastewater networks 60 72 In each issue Editor’s welcome .................................................. 1 A word from the ENA .......................................... 6 A word from WSAA ............................................ 10 News briefs ......................................................... 12 Advertisers’ index ............................................ 108 Editorial schedule ............................................ 108 96 106 Utility magazine is bringing together experts on various fields to answer all your questions ENERGY NETWORKS The evolving role of power utilities in Australia: placing paramount importance on customer experience ................................... 64 Levelling the playing field for local energy through tariff reform ...... 68 Proactively managing networks 70

A WORD FROM THE ENA

JOHN BRADLEY CHIEF EXECUTIVE OFFICER – ENERGY NETWORKS ASSOCIATION

Henry Ford, pioneer of the assembly line, is famously quoted as saying his customer could have “…any colour he wants, so long as it’s black”. In practice, there were a few of the great Model T Fords made in grey, green, blue and red.

Our technology today permits consumer choice and the customisation of products and services on a global, 24/7, peer-to-peer sharing scale. While the customer was always king, their royal command is increasingly anticipated by a learning algorithm with a personalised experience.

Customisation looks set to become the ‘new normal’ in energy, where the low-engagement commodity is being replaced by a services market focused on customer needs, drivers and aspirations. The Internet of Things is converging, with distributed energy resources and digitisation transforming the energy system, which was originally designed for the one-way flow of energy from large-scale producers to consumers. Today, the system is becoming a two-way exchange network, enabling the exchange of energy and information, and increasing consumer choice.

While the grid is still critical to the safe and reliable supply of electricity, a multiplicity of options for customers to interact with the system have been added to the mix: rooftop solar panels, energy storage systems, electric vehicles, home automation, energy management systems, and advisory services. With over 14 million customer connections, energy networks are the platform for enabling this customer interaction with energy services and technology.

The Consumer Engagement Handbook is an initiative under the ENA and CSIRO Electricity Network Transformation Roadmap. It builds on the Roadmap’s Interim Report released at the end of 2015, which recognised that there is no single energy customer, but rather they are increasingly diverse.

The Handbook has been developed with input from consumer representatives and informed by CSIRO social science expertise. It aims to complement existing guidance, such as that from the Australian Energy Regulator (AER), and the leading work of key customer advocates, including Energy Consumers Australia. It is not the final word, but a living document designed to foster continuous improvement and information sharing, tailored specifically to engagement in the energy sector.

Australia’s energy sector has increased effective engagement in recent years. Energy network providers now undertake significant engagement with customers in the development of five-year plans and proposed tariff structures, to inform network planning and maintenance and vegetation management, and in recovering from natural disasters. These activities are already guided by the Consumer Engagement Guideline for Network Service Providers released by the AER in 2013. The AER’s Guideline aims to help network service providers develop consumer engagement strategies and approaches, and also help them prepare spending proposals that reflect consumers’ long-term interests.

With so much experimentation underway in new engagement methods, and with so much time and investment by customers, stakeholders and energy providers, the Consumer Engagement Handbook seeks to share insights. The goals of the Handbook are to:

• Provide best practice guidance to ENA member businesses for engaging with consumers

• Strengthen relationships with consumers and consumer groups

• Support the use of performance measurement and indicator tools in engagement activities

• Provide the opportunity for continuous learning and evolution of engagement activities

• Leverage and expand the relationships between networks.

The Handbook features practical examples of engagement practices across the utility sector to provide guidance on the coordination of future engagement activities between energy network businesses, energy institutions and consumers.

It is recognised by energy network businesses that effective evaluation requires reliable and valid measurement of key indicators. Similarly, as part of their five-yearly assessment of energy network businesses’ revenue proposals, the AER considers the extent and quality of community engagement. However, despite the clear importance of consumer engagement and the value in continuous improvement, there are few standard measures to evaluate success.

The Handbook identifies a set of Key Performance Indicators and how they could be measured. It also identifies the importance of establishing an engagement culture incorporated into business planning and strategic goals.

8

Combined with extendable track width for side-hill stability, a durable one-piece hinged hood, and Vermeer’s legendary build quality and unmatched local dealer support, you’ve got the ideal partner for today’s fibre installation environment.

Same familiar controls More metres in the ground Gets there faster Access all areas Vermeer and the Vermeer logo are trademarks of Vermeer Manufacturing Company in the United States and / or other countries. © 2014 Vermeer Corporation. All Rights Reserved. D9X13 NAVIGATOR ® S3. GET EQUIPPED. / VermeerAustralia WWW.VERMEER.COM.AU | 1300 VERMEER WWW.VERMEERWA.COM.AU | 1800 195 558 (WA & NT) VERMEER’S D9X13 NAVIGATOR® SERIES 3 THE NEW LEADER IN LEAD-INS GET

THE NEW

THROUGH MORE SHOTS EVERY DAY WITH

VERMEER D9X13 NAVIGATOR® S3. Featuring a 26% increase in carriage speed, a 37% increase in ground drive speed, and a narrow profile to get to the most confined job sites, the Series 3 D9x13 Navigator helps you fit more metres into to the working day.

A WORD FROM THE ENA

During the development of the Consumer Engagement Handbook, clear feedback from both network businesses and stakeholders was that, for consumer engagement to be successful, network businesses must:

• Demonstrate how a particular piece of engagement fits into the overall engagement plan

• Attempt to include views from all relevant stakeholders, including hard-to-reach groups, and ensure those engaged are representative of the entire community

• Be clear about the goals of the engagement and the performance measures

• Be clear about “wriggle room” – if there are limits to what the response to engagement outcomes can be, these need to be clear up-front

• Ensure those who are engaged can identify where and how their feedback has been taken into account.

Customising energy services is now possible in ways

that Henry Ford would never have imagined. The customer experience can now be shaped not only by traditional retailers, networks and new providers, but by each customer themselves. This will create as many new challenges for supporting vulnerable customers as it will opportunities for better engagement.

An investment in effective, genuine engagement can unlock not only better outcomes for our customers, but the long-term sustainability of our own businesses.

Find out more about the Electricity Network Transformation Roadmap and the Consumer Engagement Handbook from the ENA website, www.ena.asn.au.

John Bradley Chief Executive Officer Energy Networks Association

10

378 BVCI Utility Half Page ad final out.indd 1 12/11/15 10:22 AM

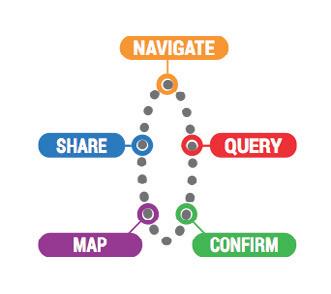

MAKE INFORMED DECISIONS ABOUT YOUR ASSETS

DEVELOPING ADVANCED MOBILE AND SPATIAL TECHNOLOGY SOLUTIONS TO SOLVE COMPLEX ASSET AND DATA MANAGEMENT CHALLENGES IN THE UTILITY, TRANSPORT AND GOVERNMENT SECTORS.

For more than 20 years, Geomatic Technologies have worked closely with essential infrastructure owners, operators and maintainers, meeting their unique needs with technology solutions that capture, assess, manage, and report on asset condition and performance.

As a division of Select Solutions, our key strength is in creating solutions that deliver ‘Asset Intelligence’. Empowering infrastructure businesses to make truly informed decisions about their network.

TO FIND OUT ABOUT OUR MOBILITY AND SPATIAL SOLUTIONS

email: enquiry@geomatic.com.au

www.geomatic.com.au

www.select-solutions.com.au

your partner in metering & asset intelligence

A WORD FROM THE WSAA

ADAM LOVELL EXECUTIVE DIRECTOR – WATER SERVICES ASSOCIATION OF AUSTRALIA

Compared to other infrastructure and essential service sectors, the urban water sector is often overlooked. Nevertheless, the fundamental requirements of having world class urban water systems and infrastructure (with assets with a value of over $160 billion as at 1 July 2015) delivering the necessary public health, liveability and productivity outcomes of our cities and communities cannot be understated.

Urban water in Australia has been ‘self-funded’ and corporatised since the early 1990s, allowing newly formed businesses to seek new innovations and private sector partners to drive efficiencies without loss of service. The industry delivers high quality water and wastewater services, as measured independently in the National Performance Report. It recovers the costs of these services from customers, and does not rely on budget funding or large announcements to construct infrastructure. While bills to our customers have increased to fund water security, satisfaction levels remain high and complaints (as recorded by various state ombudsmen) are significantly lower than many other sectors. All of which means, in some policymakers views, urban water lacks a burning platform for reform.

However, to avoid urgent and costly decisions in the future, there is a strong case for renewed national policy leadership.

Last November, WSAA, in partnership with Infrastructure Partnerships Australia (IPA), released the report Doing the important, as well as the urgent: reforming the urban water sector. Launched by Treasurer Scott Morrison, the report calls on the Commonwealth Government to drive a new five-year program of reform across the states and territories, supported by meaningful financial incentives and including a new National Water Initiative.

Australians continue to enjoy world class water and wastewater services, and water utilities are focusing on driving increased customer value and affordable bills. But to continue to do that, the regulatory and governance structures they operate in need to be refreshed to promote the long-term interests of customers.

Over the last few years there have been a series of reports by federal bodies, such as Infrastructure Australia, Harper Competition Review, the now abolished National Water Commission and the Productivity Commission, that all point to an emerging need for a renewed commitment to national leadership in water management, coordinated infrastructure planning for the built environment and a focus on new ways of regulating the sector to focus on customer value and provide the right conditions for more innovation. With existing settings, we are poorly equipped to meet this need.

Most recently, on 17 February 2016, Infrastructure Australia released its Australian Infrastructure Plan. While media reporting focused on transport and roads, there were also recommendations in the plan relating to urban water, including a recommendation for better independent economic regulation of the sector and the establishment

of a national water framework. Specifically, recommendation 6.12 states that the Federal Government should work with state and territory governments to establish an independent national body to deliver a National Water Reform Plan.

WSAA supports this recommendation. In our report on reforming the urban water sector, we call for a permanent national champion for urban water reform. We believe now is the time to position the urban water sector so that it can better meet the challenges ahead, at the least cost to the community.

To address these challenges we recommend that Australia needs national leadership in urban water policy. Although urban water is owned, operated and regulated by sovereign states, there is a strong case for renewed national leadership in urban water policy, in the interests of customers, the environment and national economic productivity.

As we look to the future, urban water needs to be better integrated in to city planning, including coordinated integration of stormwater services to meet community expectations of our highly valued liveable cities and communities. Urban water utilities play important roles in providing everything from clean beaches and waterways, through to contributing to public health and national economic priorities. At present, opportunities to improve liveability are forgone due to unclear roles and responsibilities between policymakers and corporatised water utilities.

Beyond that, water utilities are well placed to harness the benefits of the digital transformation currently underway in the economy. Utilities collect millions of data points, demonstrating the growing benefits of artificial intelligence; utilities with thousands of kilometres of pipes and hundreds of facilities are ripe to reap the benefits of the Internet of Everything; and finally water utilities deliver essential services 24/7, 365 days of the year. The explosion of wet wipes as an issue in the past two to three years has shown that immediate and grassroots engagement with customers using Facebook and Twitter can rapidly bring an issue alive and drive change very quickly.

Water utilities in Australia and New Zealand continue to develop and undertake significant benchmarking programs. This year the Asset Management benchmarking program (the Asset Management Customer Value project) will be delivered. Together with the highly successful collaboration with Isle Utilities (based in the UK) to assess pre-commercialised technology and innovations across the entire urban water cycle, utilities are working hard to be as efficient and effective as possible, while looking over the horizon at emerging technologies.

WSAA will continue to advocate for renewed national policy leadership – backed with meaningful incentives – to elevate the consensus about the importance of good water policy into an actionable national leadership initiative.

Adam Lovell Executive Director Water Services Association of Australia

12

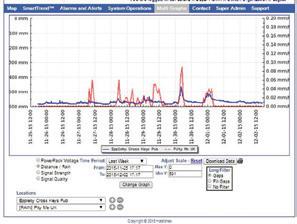

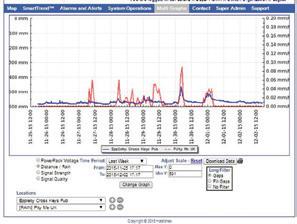

METASPHERE TELEMETRY PROVIDES ROBUST ASSET MONITORING:

WATER, WASTEWATER & STORMWATER - IP68 RTU’s

SMART METERING - Analogue, Digital, Pulsed and Serial Inputs

GAS & MINING SECTORS - Intrinsically Safe RTU’s

ENVIRONMENTAL MONITORING & REPORTING - River flows, Flooding, Rainfall

OPERATIONAL LICENSING & REQUIREMENTS

ROAD & MARITIME APPLICATIONS

BENEFIT FROM OUR 4Cs:

1

2

COLLECT

Telemetry Data; Alarms; Trends

CONNECT

2G, 3G

Secure IP; PSTN; Radio & Satellite

Collect data from remote assets and meet regulatory compliance

email info@metasphere.net.au

or call 1300 785 681

www.metasphere.net.au

3

palette palette palette

4

COMMUNICATE

Visualisation & Reporting Decision Support

CONTROL

Assets; Network; Performance

AEMO WARNS OF GAS SHORTAGE

Developed gas reserves in eastern Australia will only meet demand until 2019, a report from the Australian Energy Market Operator (AEMO) warns.

Market data from the AEMO’s 2016 Gas Statement of Opportunities (GSOO) shows gas reserve development is required by 2019 to maintain long-term gas supply adequacy in eastern and south-eastern Australia.

AEMO Managing Director and Chief Executive Officer Matt Zema said that while there are no gas supply shortfalls forecast until 2029, the 2016 GSOO shows that developed gas reserves in eastern and south-eastern Australia are only sufficient to meet forecast gas demand until 2019.

Mr Zema said, “This means that currently undeveloped gas reserves, including those reported as contingent resources and possible reserves, will be required to ‘come online’ to meet forecast demand as early as 2019 when

developed reserves are forecast to start to deplete.”

Mr Zema said that the need to convert undeveloped gas reserves and resources into working gas fields from 2019 reflects forecasts from AEMO’s 2015 National Gas Forecasting Report (NGFR), which projects that total annual gas consumption in eastern and south-eastern Australia will double over the next five years to 2020 as Queensland’s liquefied natural gas (LNG) export facilities ramp up production.

The 2016 GSOO uses the demand forecast scenarios from the 2015 NGFR, and production and supply information provided by industry, including wholesale gas contract information, to assess the adequacy of gas infrastructure and resources to meet demand in eastern and southeastern Australia to 2035.

The GSOO is based on data provided by industry participants up to 10 December 2015.

“The need to convert undeveloped gas reserves and resources into working gas fields from 2019 becomes clearer still when we take export LNG demand out of the picture,” Mr Zema said.

The Australian Petroleum Production and Exploration Association (APPEA) said governments in eastern Australia must pull out all stops to encourage the investment needed to address predicted gas shortages highlighted by AEMO.

APPEA Chief Executive Dr Malcolm Roberts said, “The information released by AEMO is a sobering reminder that the east coast needs rapid development of new gas reserves to guarantee supply.

“We have long argued that if we wish to achieve a more competitive market, put downward pressure on prices and ensure stable, adequate supply, we must bring more gas to market.”

TRANSGRID APPOINTS NEW CEO

The former CEO of Western Power has been announced as the new Chief Executive Officer (CEO) of TransGrid.

TransGrid has appointed Paul Italiano as its new CEO, effective from mid-2016.

Having recently completed its 99-year lease transaction from a state owned corporation to private ownership, TransGrid is focused on providing a safe, reliable and efficient electricity transmission and related services, in an increasingly challenging and competitive market.

Mr Italiano is a transformational leader who has turned around the performance and service standards,

safety culture, operating framework and financial results of Western Power (WA) during his four-year tenure as CEO.

When Mr Italiano takes up his position midyear he will replace Peter McIntyre, who has led TransGrid since 2010.

In the interim, Ian Stirling will act as CEO. Mr Stirling is most notably known for his successes as CEO over a 12year period with the South Australian electricity transmission business ElectraNet.

TransGrid Chairman Rick Francis said, “On behalf of the board and NSW Electricity Networks as the new owners, I want to both acknowledge

and thank outgoing CEO Peter McIntyre for his stewardship of the business over his many years of service.

“Peter was instrumental in building a successful corporatised business in a state-owned environment and facilitating an extremely successful outcome from the NSW Government’s privatisation process.

”I am very much looking forward to working with Paul to take TransGrid to its next level of development. His dynamic leadership style, commercial acumen and proven ability to transform a business in the face of significant challenges make him an excellent choice for the role.”

NEWS 14

Contact us today for a quote NSW 02 9605 4723 QLD 07 5573 2694 | www.pmaus.com.au

and resource projects

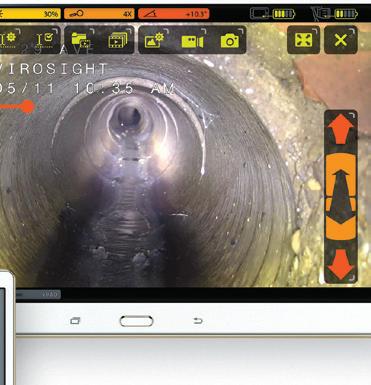

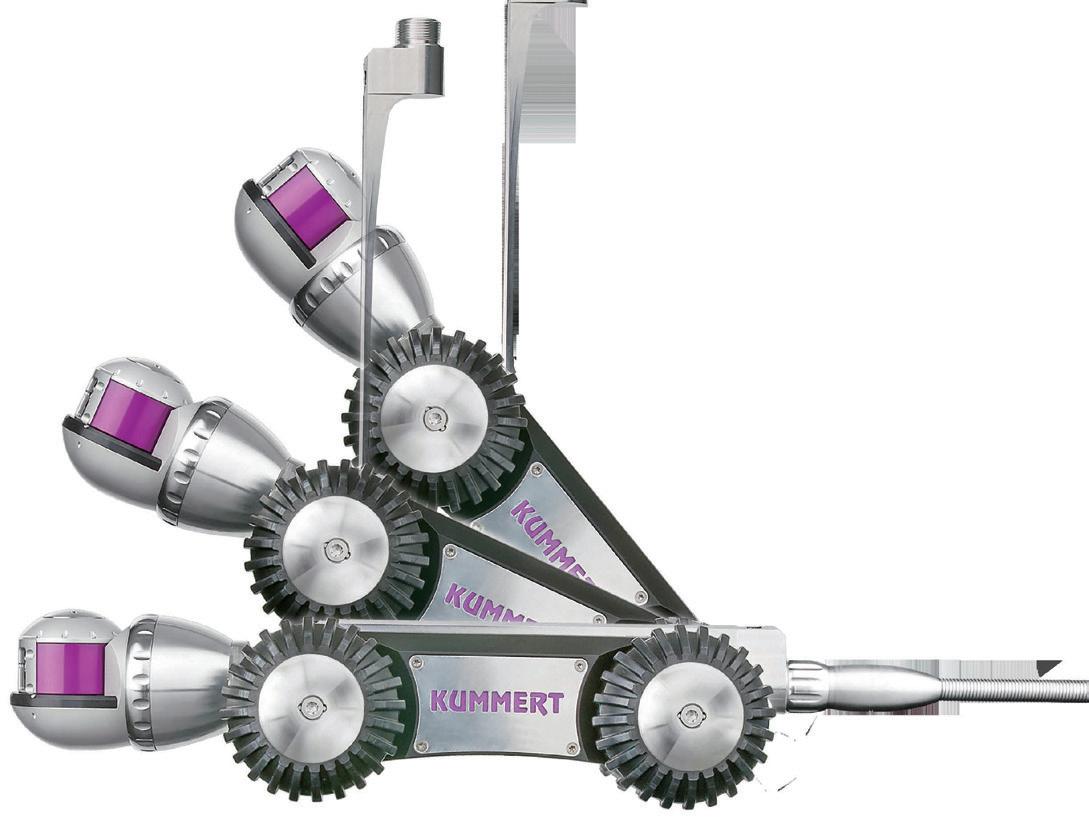

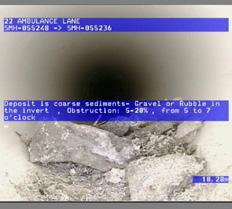

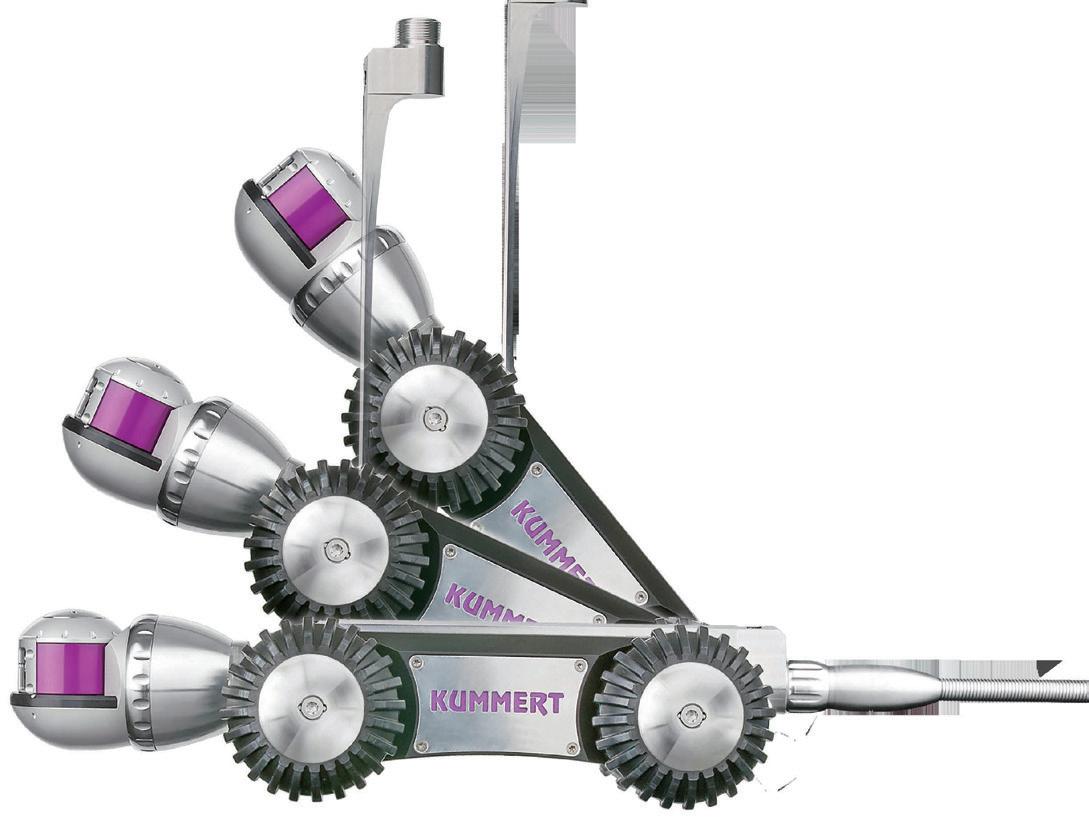

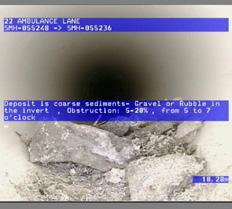

MICROTRAXX CCTV

MAINTENANCE

Pipe Management Australia is a professional, capable contractor preferred on many of Australia’s largest construction

HYDRO EXCAVATION

PIPE INSPECTIONS Utility Maintenance Contractors DRAIN

VIC GOVERNMENT ORDERS DESALINATED WATER

The Victorian Government has placed an order for 50 gigalitres (GL) of desalinated water to be delivered in Summer 2017 to help Melbourne’s low water levels.

Melbourne’s water storages have been declining steadily for the past two years and have dropped by 152GL in the past year.

Victorian Premier Daniel Andrews said “We’ve always said the desalination plant is our insurance policy to secure our water supply and boost the amount of water available in the water grid – now it’s in Victoria’s best interests that we call on that insurance.

“As our population continues to grow and our state faces drought, we need to secure water supplies for Victorian communities – and adding

desalinated water will help us meet these challenges.”

Advice provided to the Government by Melbourne Water, in consultation with the three metropolitan retailers, recommended placing a water order of 50GL.

The advice is based on a detailed analysis that considers current water levels in the storages, the likelihood of low inflows, dry conditions in the short term, and forecast demand.

Victorian Minister for Environment, Climate Change and Water, Lisa Neville, said, “The Government has responded to the advice of Melbourne’s water corporations and will place an order to help provide Melbourne and our region’s water security.

“We’re taking action so that kids don’t have to play on rock hard ovals,

NEW ENERGY RETAILER ENTERS AUSTRALIAN MARKET

Australia has a new energy retailer, aiming to help consumers use more renewable energy.

The Australian Renewable Energy Agency (ARENA) and SBCVC have backed a $5 million Southern Cross Renewable Energy Fund investment into new retailer, Mojo Power.

ARENA CEO Ivor Frischknecht said “Mojo Power supplies electricity to its customers at cost and charges a fixed monthly fee. This allows Mojo to focus on working with customers to unlock cheaper energy bills through solar, storage and energy efficiency.

“Australians have embraced

residential solar in big way, with a world-leading 20 per cent of households so far installing panels on their roofs.

“Using state-of-the-art smart metering technology, Mojo will be able to analyse customer usage data with a view to optimising energy use and demonstrating how households could benefit from renewable energy technologies.”

Mr Frischknecht said customers will be able to access more information about their energy usage, making them better placed to take the steps needed to run smarter homes.

“If Mojo successfully taps into the

so gardens and sporting ovals are green and will ensure a secure water supply for schools, hospitals and homes from Melbourne to Ballarat.”

The order will increase the amount of water that could be moved through the water grid – which assists water security for Ballarat, where storage levels currently sit at 52 per cent, Geelong, which is sitting at below 40 per cent, and other regional communities.

The cost of the order will add $12 a year to the average metropolitan water bill, however a Melbourne Water proposal being considered by the Essential Services Commission could reduce water bills by more than that amount.

Australian market, it could encourage even more households to invest in solar, which in turn will help drive down costs.

“It also has the potential to accelerate the growth of Australia’s emerging battery storage industry as consumers look for more value from their rooftop systems.”

The investment from the Southern Cross Renewable Energy Fund will help Mojo with market-entry and business expansion activities.

Mojo founder and CEO James Myatt said “Mojo’s model is a real game changer and it will benefit those households that currently face high electricity bills. We are absolutely aligned with the customers’ primary objective, which is to pay less for the electricity they need.”

NEWS 16

THE ORDER OF DESALINATED WATER WILL SECURE MELBOURNE’S WATER SUPPLIES AND HELP KEEP THE CITY GREEN.

INMARSAT SERVICES AVAILABLE ON AUSTRALIAN SATELLITE NETWORK

Pivotel Satellite has launched Inmarsat voice services for its customers, providing Pivotel customers with access to Inmarsat’s reliable global L-band voice connectivity throughout Australia.

Pivotel is well known for uniquely providing standard ‘04’ Australian mobile numbers across its entire range of satellite voice services, but until now, Inmarsat satellite voice customers in Australia have been unable to take advantage of this facility. Now, with a Pivotel Inmarsat service, users benefit from simple, domestic dialling, and callers pay only the rate of calling an Australian mobile phone which in many mobile bundles is free. An 04 mobile number also allows companies with satellite phone fleets to use multiple satellite technologies and call between them at standard mobile call rates.

“Inmarsat services are a great addition to Pivotel’s Licensed Australian Carrier Network,” said Pivotel Group CEO

Peter Bolger. “With over 30 years’ experience, Inmarsat, like Pivotel, is renowned for its high quality network, so a partnership to deliver Inmarsat voice services over the Pivotel network is a great outcome for both companies, and for Inmarsat’s existing and prospective customers in Australia and New Zealand. We expect the increased value and simplicity from using the Pivotel Inmarsat service will result in a large increase in the number of Inmarsat users in our part of the world.”

“It is partnerships like these that will drive Inmarsat’s present and future business successes,” said Greg Ewert, President, Inmarsat Enterprise. “Our mission of powering global connectivity can only be realised through the efforts of our innovative partners. I’m pleased to work with Pivotel to bring Inmarsat’s reliable voice connectivity to its customers.”

JEMENA’S EASTERN GAS PIPELINE EXPANSION NOW OPEN

Jemena has opened its Eastern Gas Pipeline (EGP) expansion, which connects gas from Victoria’s Gippsland Basin to the east coast market.

The expansion has increased capacity of the pipeline by 20 per cent, and will provide for the growing demand for natural gas on Australia’s east coast.

The EGP is a 797km pipeline transporting gas from Victoria’s Gippsland Basin to Sydney, the ACT and regional New South Wales.

The EGP was commissioned in 2000, and the recent $150 million expansion involved the installation of two new midline compressor stations at East Gippsland and Michelago, plus additional delivery facilities at Wilton.

The EGP can now transport at least 22PJ more gas each year into NSW, which is enough to supply around one million NSW homes for a year.

The EGP supplies more than half the gas consumed in NSW, and on many occasions this year has transported 100 per cent of the gas used in the state.

The EGP feeds into the company’s distribution network,

which delivers natural gas to more than 1.2 million homes and businesses across Sydney and regional NSW.

Jemena Managing Director Paul Adams said demand for gas in NSW remained strong, despite a challenging outlook in the short term driven by tighter domestic supply.

“We expanded the EGP so we can keep gas competitive by moving more much-needed supply into NSW,” Mr Adams said.

“Last year, we connected more than 44,000 new customers to gas. Over the next five years, we expect to add more than 185,000 new customers to our network, so they can also enjoy the benefits of affordable, reliable, responsive and low emissions natural gas.”

Mr Adams said Jemena had committed to invest nearly $1 billion in its pipeline assets over the last few years, increasing capacity and establishing new delivery points to offer customers even more competitive and reliable transport and storage options.

18 NEWS

CENTRALIZER & SPACER SYSTEMS FOR THE DRILLING & CIVIL CONSTRUCTION INDUSTRIES HDX Series Spacer

Meet the challenges head on

• Handles Steel, DICL, MSCL, Concrete & HDPE pipe plus contents 4” up to 63” OD and beyond

• Positions pipe within casing for customised centering or restraining

• Minimizes running friction and drag on very low co-efficient of friction wear pads with superior abrasion resistance properties

• Resists chemical and oils and maintains strength even if immersed for long periods of time

• Arrests vibration transfer from outer casing and reduces point loading via unique load sharing runner system

• Contains no lead or metal parts, fully compatible with municipal water applications

Warehouse locations:

Sydney NSW, Australia

Bunbury WA, Australia

Dallas TX, USA

www.kwikzip.com

& restrained Spacer comprised of the same HDX 65 segment (65mm runners) Non-centered & restrained Spacer comprised of HDX 125 segments (125mm runners) above the pipe and HDX 65 segments (65mm runners) below pipe

& restrained Spacer comprised of HDX 65 segments (65mm runners) above pipe and HDX 125 segments (125mm runners) below pipe

Centered

Non-centered

Australian & International Customers +61 8 9725 4678 sales@kwikzip.com USA Customers +1 972 790 0160 usa@kwikzip.com

Utility Partner Solutions

THE UTILITY CHALLENGE: CONSOLIDATION OF ENTERPRISE APPLICATIONS

What if I told you that most Australian utility companies and utilities service providers could improve asset utilisation and maintenance, increase efficiency, and reduce risk if their enterprise systems were better integrated?

By Rob Stummer, Managing Director, IFS Australia and New Zealand

It might cross your mind that utilities and utility service providers have already invested in enterprise software. While that’s true, the structure of the industry has been a barrier to integrating systems across supply and value chains.

In IFS’s experience, utility companies that excel at asset lifecycle management and efficient service and maintenance have a significant competitive advantage.

As a result, most enterprise solutions cannot deliver the benefits of cradle to grave asset lifecycle management, for example. There’s also a question mark over whether they are modern and agile enough to fully benefit from disruptive new technologies like the Internet of Things.

If you think that sounds like bad news, think again. The good news is that the potential to improve efficiency, lower costs and reduce risk is still enormous.

STRUCTURAL BARRIERS TO INTEGRATION

Most asset-intensive industries tend to operate in an isolated or siloed manner. In utilities there is poor information exchange between business units at two levels. The first is within larger enterprises, and the second is between asset owners and service providers.

Asset owners have traditionally invested in Enterprise Asset Management (EAM) systems. Companies or business units that build or install assets, however, usually employ specialist design or bestof-breed Project Management solutions. Service companies or divisions often use standalone Workforce Management or Field Service Management (FSM) solutions.

Enterprise Resource Planning (ERP) systems are the main enterprise solution in most industries. They are often perceived as a poor fit by asset-intensive utilities, however, because they may lack a full-blown, integrated set of EAM modules. As a result, utilities often use ERP only for financials and don’t integrate it with other enterprise systems.

POTENTIAL TO IMPROVE EFFICIENCY

What we’ve mostly ended up with in utilities is a fragmented mix of software, with ERP used for financials, EAM and/ or FSM for maintenance and service, and standalone tools to manage projects. With little integration, information flows between business units or companies are usually poor. Better integration could greatly improve coordination of business processes across different areas – with huge potential to improve operational efficiency.

Connected, real-time information systems also reduce operational and financial risk. If financial or ERP systems are not integrated with operational systems they cannot share information in real time. The bottom line impact of operational decisions only becomes apparent after producing end of month reports. It’s a bit like driving a car while only looking in the rear-view mirror –definitely not recommended.

In IFS’s experience, utility companies that excel at asset lifecycle management and efficient service and maintenance

“

have a significant competitive advantage. To be successful, however, they need enterprise software capable of supporting operations and maintenance, not just financials.

With major capital projects, there also has to be a focus on the project management of the initial asset design. The integration of design and Project Management systems with ERP and EAM solutions has a massive payback. The effective handover of new assets from design to construction into operations leads to a raft of benefits. These include greater uptime and reliability, and leaner supply chain and procurement processes.

DATA-DRIVEN COLLABORATION

Service and maintenance are among utilities’ biggest costs. Any lack of transparency into standalone systems throughout the service supply chain must also be addressed. Taking all the elements into account, an integrated combination of ERP, EAM, Project Management and Enterprise Service Management (including FSM) is the ideal solution.

Enterprise solutions providing transparency and collaboration between business units or companies can over-

come the structural barriers to greater end-to-end productivity. They can provide a platform to drive industry consolidation or enable more collaborative, data-driven working models.

Utility industry executives I have spoken to say that it’s possible to deliver the right value chain if you get the right stakeholders around the table. In particular, you can create new value propositions around managing assets from the cradle to the grave. That is a real benefit for both asset owners and service suppliers.

BETTER WORKFORCE MANAGEMENT

Some of the greatest synergies can be achieved through better workforce management. Skilled resources are always in high demand, and rises in the cost of labour have driven up project, maintenance and service costs. The smart use of technology can improve labour utilisation to restore or achieve even greater levels of productivity.

With visibility into both tasks and available labour across the supply chain, you can make better use of employees and contractors. If you can see which maintenance workers are trained, compliant and available, for example, you can inject them into a project. That can speed up delivery, improve labour utilisation and offer contractors more consistent work.

Ultimately, modern enterprise technologies like Enterprise Service Management, mobility support for real-time data capture and access, and real-time business intelligence systems will revolutionise the way that utility services are provided.

Real-time data access and capture for projects or service and maintenance operations is already possible with solutions like IFS Mobile Work Order. Both employees and sub-contractors can access and update relevant information on site. Workers can use the mobile device of their choice, improving coordination, productivity and transparency.

Rob Stummer is the Managing Director, Australia and New Zealand for global enterprise applications company IFS. He has held this position for the past 8 years, continually achieving significant growth annually in both revenues and EBIT. Rob holds several degrees, including a Masters from Melbourne University. See: www.ifsworld.com/au

FUTURE TECHNOLOGY BENEFITS

In the very near future a host of new technologies – like Enterprise Operational Intelligence, 3D Printing, wearable devices and the Internet of Things – will boost efficiency even further.

At IFS, we have been developing Enterprise Operational Intelligence technology to turn a company’s “Big Data” into something useful. We can create a real-time map of the entire value chain and link it to enterprise software to monitor processes via key performance indicators to deliver on strategic goals.

Integrating new technologies with existing systems will be crucial, which means your enterprise solution must also be modern and agile enough to adapt. Implementing systems in isolation – without linking them to a big picture solution – may lead to disappointing results.

Ideally, you want all information about your assets, people, finances and projects to be in the one place – a single source of truth.

The fewer enterprise systems and databases you have, the more effectively you can analyse operations and act on business intelligence. Ideally, you want all information about your assets, people, finances and projects to be in the one place – a single source of truth. That is why IFS offers a comprehensive, modular and adaptable solution for utilities.

IFS got its start in the nuclear power industry in Sweden, and is a recognised leader in enterprise asset management for utilities globally. We’ve built a very strong base of customers in Australia, and we’re working hard to show how modern, agile enterprise systems can optimise the operations of more utility companies in the future.

For more information visit: www.IFSWORLD.com

Phone: 1300 791 200

AGILE BUSINESS

FOR

“

ABOUT THE AUTHOR

MANAGING VICTORIA’S BUSHFIRE RISK WITH SPATIAL SURVEYING

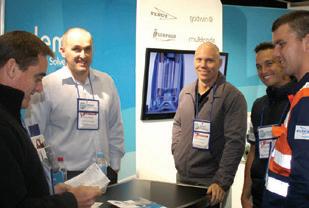

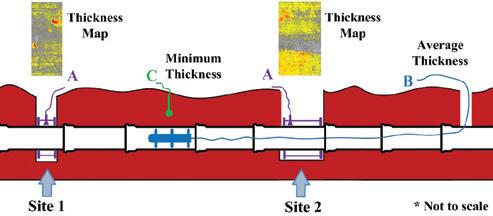

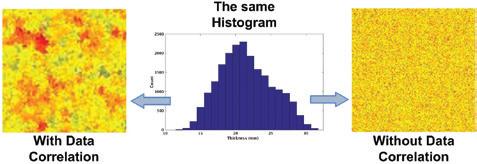

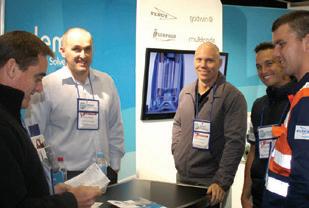

Mitigating the risk of fire associated with certain electricity assets is vital in Australia’s bushfire prone climate. However, traditional methods of surveying large electricity networks are costly and time-consuming. Recently, Geomatic Technologies completed works surveying parts of the Powercor and AusNet Services electricity networks in Victoria using an innovative method that greatly reduced the time and expenditure required.

MAPPING, GIS & SURVEYING

REDUCING THE RISK OF FIRE

The award-winning Bushfire Safety Clearance Program was undertaken by Geomatic Technologies. The program employed a combination of positioning technology, LiDAR scanning and image processing to measure conductor clearances and identify sections of the networks requiring remedial action to prevent poorly spaced conductors potentially sparking fires.

Following the Black Saturday bushfires in February 2009 and subsequent inquiry, the Victorian Bushfire Royal Commission made 67 recommendations to reduce the likelihood of a similar disaster recurring. These included a recommendation that spreaders be fitted to any electricity lines with a history of clashing or the potential to do so.

Conductor spacing is an important aspect of electricity asset management and bushfire mitigation due to the fire risk posed when lines are too close to each other, or to vegetation, the ground or other objects.

“During windy and hot conditions, conductors may sag and make contact causing ‘arcing’, which significantly increases the risk of a fire ignition,” said Mathew Croft, Business Manager (Power and Telco) at Geomatic Technologies. “Therefore, maintaining safe conductor clearances on electrical networks is important for bushfire mitigation and, ultimately, public safety.”

Following the adoption of the Royal Commission’s recommendations by the Victorian Government, Victorian electricity utilities were required to assess conductor separation throughout their networks. Recognising the need for a more efficient method of measuring powerline clearances throughout their large networks, AusNet Services and Powercor engaged Geomatic Technologies (GT) to develop a custom solution.

FINDING A BETTER WAY

The Bushfire Safety Clearance Project required the integration of multiple sensors, as well as a custom software application to process and model the conductor infrastructure to meet

the Australian distribution conductor modelling standard.

Having undertaken infrastructure clearance studies using LiDAR in the rail industry for over a decade, GT’s team was experienced in developing custom solutions to meet complex compliance requirements of this type.

Accurately and effectively measuring conductor clearances throughout the Powercor and AusNet Services networks and identifying potential clearance issues required various different data types to be collected. These comprised:

• LiDAR data (a surveying technology using pulsed laser to measure distances, also known as 3D laser scanning)

• GPS coordinates

• 3D Panoramic street-level imagery

• Inertial data (mobile survey only)

• Weather data – air temperature, wind speed, wind direction.

“The previous method of collecting this data was via a traditional survey team,” said Mr Croft. “The surveyors would normally use a total station to collect measurements at the pole and several points along the conductor. This method would normally only achieve a handful of points on each conductor and beneath each span. Using LiDAR we can generate a complete point cloud of the entire span with hundreds of measurements along each conductor.

“Due to the number of spans required to be surveyed by the regulator (Energy Safety Victoria), traditional survey methodology was not practical from cost and time perspective.”

SURVEYING EXPANSIVE NETWORKS EFFICIENTLY

Throughout the project, GT surveyed large sections of the electricity networks, requiring effective management of the survey teams to ensure the works were completed as efficiently as possible.

For instance, the AusNet Services conductor clearance survey consisted of approximately 15,000 spans, which were progressively completed in successive stages. “Each stage is broken up into general regions and

MAPPING, GIS & SURVEYING 23

then split into sites of approximately 100 contiguous spans or less,” said Mr Croft.

To efficiently survey such large spans GT employed its GT AIMS 3D (Asset Inspection Management System), which incorporates 3D panoramic imagery and LiDAR sensors, mounted on a survey vehicle.

“The mobile survey can capture many spans in fast succession – it takes as long as it does to drive along the length of the span,” said Mr Croft. “If the span is not traversable by vehicle, then the terrestrial survey method is required, where GT surveyors will use a Riegl VZ400 3D laser scanner to generate a point cloud to fill in the gaps that the mobile vehicle cannot traverse.”

GIS technology played a large role in managing the deployment of the survey teams.

“In terms of managing the two teams and the spans required to be surveyed, we heavily utilised GIS to manage the status of every required span. GT used AIMS Karta, its in-house field capture software, to manage the field teams’ progress. The mobile field crew would mark off which spans were captured and which spans would require the terrestrial survey team to visit. The terrestrial survey crew would then mark off which spans they had captured. All of this data was sent back to a server, which could be viewed from the office. Each time the field crews would sync the data the office team would get an update on which spans had been captured and which spans remained.”

PRECISION CLEARANCE MEASUREMENT

As well as this survey method being significantly quicker and cheaper than traditional methods, it also enables very precise clearance measurements, the accuracy of which were verified by AusNet Services through a separate auditing exercise.

Once the collected data was processed, special software, GT AIMS Catenary, was used to manage desktop-based data analysis, feature classification and catenary modelling.

This software integrates 3D imagery with LiDAR, conductor loading information

and weather data, and then automatically reports any clearance violations. Additionally, it also allows equipment to be mapped and asset condition to be assessed.

While the inspections were primarily focused on clearances between conductorto-conductor, conductor-to-ground and conductor-to-structure, GT also analysed conductor-to-vegetation clearances.

As the system does not rely on any existing engineering design packages, it could be tailored to the specific requirements of the application.

OVERCOMING THE CHALLENGES OF THE VICTORIAN LANDSCAPE

The Victorian landscape posed an array of different challenges that had to be overcome by the survey teams. These challenges related not only to the variable terrain and requirement for off-road driving, but also extreme hot or cold conditions, landowners, environmental concerns, logistics, livestock and wildlife.

“The mobile field team were almost constantly challenged by terrain,” said Mr Croft. “The vast majority of high bushfire risk spans are located in rural areas, which are often traversing farm paddocks. Spans cross creeks, rivers and gullies really well – 4WD vehicles don’t. AusNet Services distribution area covers a lot of hilly terrain and a lot of farmland. All field crew members were trained in correct and safe 4WD operation and vehicle recovery.

“During the warmer months the team were faced with dangerous fire conditions and were instructed to avoid driving on private property during days of severe, extreme or catastrophic fire danger days or days of total fire ban.

“Driving from farm paddock to farm paddock added an environmental complexity, where crews had to maintain vehicle cleanliness standards and ensure that mud or seeds were not transported from farm to farm,” said Mr Croft.

“The terrestrial team were often carrying survey equipment across the terrain that the mobile vehicle cannot drive on, and often involved hiking into inaccessible areas.

“Snakes, spiders, wasps, cattle and dogs were all various issues dealt with on a daily basis.”

At one stage the teams also needed to

access the Hazelwood mine, requiring them to undergo the relevant site inductions before they could gain access.

Nevertheless, despite these obstacles, the surveys were completed well ahead of schedule.

“GT has been working through the stages since November 2012 with an end goal of completing all HBRA (High Bushfire Rated Area) spans by December 2015,” said Mr Croft.

“GT successfully reached this target in September 2015.”

A NEW BENCHMARK IN CONDUCTOR SEPARATION ASSESSMENT

The success of the Bushfire Clearance Safety Program was recognised at the 2015 Victorian Spatial Excellence Awards, winning the Award for Innovation and Commercialisation.

The judges cited the innovative combination of technologies, as well as the efficiency, accuracy and cost-effectiveness of the project as the aspects which made it stand out and which “clearly establish it as an industry benchmark”. This also puts the project in the running for the Asia Pacific Spatial Excellence Awards (APSEA).

The benefits realised through GT’s custom clearance survey solution demonstrate a highly effective and efficient method of assessing condition across large networks. As a result it is likely that there will be a much larger uptake of similar solutions in the future to detect different network defects.

Mr Croft said “Electrical utilities are faced with a continual challenge of reducing cost while maintaining network safely. GT envisages being able to assist network owners to reduce the cost of inspection and assess the network by enhancing our solution to be able to complete a ‘single pass’ with several sensors to capture data that can be used to determine various network defects, where traditional methods have required several visits via manual inspection ‘on foot’.”

All in all, the Bushfire Safety Clearance Project is a successful example of utilising technological innovation in a way which not only reduces expenditure, but also contributes to better asset management and has the potential to save property and lives.

MAPPING, GIS & SURVEYING

Expand your skillset in this rapidly developing industry with a postgrad in Geographic Information Science from Curtin University. Curtin offers fully online GIS courses, giving you the flexibility to continue working while you study. Plus our courses are designed in collaboration with industry so they’re highly practical and relevant.

Find out more at spatial.curtin.edu.au

CIRCOS Provider Code 00301J/ MF CU-SE000089A Curtin University is a trademark of Curtin University of Technology

tomorrow better. Be at the forefront of a changing world. Get an online postgrad in GIS.

Make

A $5 billion infrastructure network, 20,000km of water and sewerage mains and 1.4 million customers distributed across South East Queensland: you could safely say location is at the heart of Queensland Urban Utilities’ (QUU) operations.

Driven by a commitment to operational and customer service excellence and innovation, QUU has taken its spatial capability to the next level with the development of the award-winning portal, Q-Hub.

By ingeniously combining data from a range of disparate legacy systems into a common operating picture, Q-Hub has united and focused the organisation.

From operations personnel, to field workers, to the customer service team, each QUU employee now has access to the same comprehensive, real-time view of the entire network.

QUU Chief Information Officer (CIO)

Nina Du Thaler has been central to the innovation’s development and

implementation. Over several months, Ms Du Thaler and members of her team worked with Australia’s leading Geographic Information Systems (GIS) company Esri Australia to develop Q-Hub.

Such was Q-Hub’s success, Ms Du Thaler was named iTnews’ Utilities/ Media CIO of the Year, edging out several highly-rated contemporaries to win the award, including those involved with the Telstra Air wi-fi network and a $20 million asset management system

replacement at Melbourne Water.

Rightly, Ms Du Thaler is proud of the spatial ‘awakening’ the technology has brought to Australia’s fourth largest water distributor.

“There is no doubt that Q-Hub has bound the organisation together,” Ms Du Thaler said. “Understanding location and accessing a pictorial representation of what’s happening in our business is always very powerful.

“Spatial has been part of our world since QUU’s beginning, but until

26

Utility Partner Solutions

Q-Hub’s implementation we hadn’t really harnessed its full potential to drive innovation and decision-making, particularly at an operational and customer service level.

“The power of Q-Hub lies in being able to bring together different information sources via an integration hub, to provide a single spatial representation that many areas of the organisation can view at the same time.

“Whether it’s a field worker using their tablet to view a map of the network, a control room operator coordinating the activities of a maintenance crew in the field, or our customer contact personnel delivering emergency update information; they are all able to speak the same language.”

Ms Du Thaler said significant improvements in operational efficiency and customer service are at the top of the list of Q-Hub’s successful outcomes.

“By viewing information spatially, we can draw out inferences in data and enquire in ways we were never able to using spreadsheets and tables,” Ms Du Thaler said.

“For example, Q-Hub allows staff to visualise hotspots in the network: areas where there are multiple jobs affecting multiple customers, indicating a potentially wider issue that requires further action. They can then also see where the closest and most suitable crew is – based on proximity, skill sets and equipment on board – and dispatch them efficiently.

“In some instances, our customers experience water outages when parts of the network are turned off for repairs. Previously, because we could not be certain which customers would be affected, our staff would have to doorknock the entire street or even suburb. Now our operators can use Q-Hub to trace back from the impacted asset that has been switched off and identify the exact customers that need to be notified.

“Similarly, for planned work, we can proactively contact customers and explain what needs to be done and how they’ll be affected.”

Ms Du Thaler said having information

available in real-time was crucial to Q-Hub’s success.

“In the past there could have been a 24-hour or even week-long lag between events in the field and details becoming widely accessible back in the office.

“Now this information arrives in real-time. Our contact centre has instantaneous access and can again communicate with affected customers immediately.”

Esri Australia Utilities specialist Chris Hogan said Q-Hub helped Ms Du Thaler address a core headache for many CIOs: how to ensure legacy systems don’t weigh down company growth.

“Utilities typically have a number of separate legacy systems for areas such as operations, planning and asset management,” Mr Hogan said. “For CIOs that can present problems, particularly if these systems become outdated or incompatible as the business grows.

“However, using spatial technology as an integration platform allows organisations to bypass those concerns. Rather than simply replace the systems, they can weave them into a new spatial environment. It is a different approach but a highly successful and far easier one.”

Mr Hogan said a similar approach by QUU illustrated their commitment to innovation and commercial sustainability.

“QUU is at the forefront of a shift among water utilities – away from traditional system architectures to more integrated and responsive programs backed by real-time, spatial technology.

“What QUU has done with Q-Hub is truly innovative. They have shown how the key element of location can provide a platform for staff across the enterprise to access and share information.”

Ms Du Thaler said QUU’s staff are also becoming increasingly engaged with the spatial environment.

“To extend enablement and capabilities in an organisation requires a balance of push and pull. At times, my ICT team is educating staff and promoting technologies. At other times staff are pulling us to do more,” Ms Du Thaler said.

“The exciting thing about Q-Hub is

Q-HUB, DEVELOPED BY QUU IN CONJUNCTION WITH ESRI AUSTRALIA, GIVES THE UTILITY ACCESS TO A COMPREHENSIVE, REAL-TIME VIEW OF THE ENTIRE NETWORK.

that it has created an awakening within the organisation. Our staff, many of them non-traditional spatial users, can now see its value. We are getting a strong buy-in and being challenged about where to go next with spatial. Certainly 3D capabilities, both for training and identifying issues in the network, are high on the agenda.

“We also have plans of applying both historic and current spatial data in a more strategic planning forum, to see what it tells us about the way we support and maintain the network.

“So, while Q-Hub is driving better decision-making in our everyday operations today, it could also play a key role in planning new infrastructure and organising and delivering services to our customers in the future.”

27

MAPPING, GIS & SURVEYING

ACCURATE ASSET LOCATION DATA Enhancing Value and Confidence through

Knowing the precise spatial position of assets, especially those buried underground, allows utility operators to rapidly locate their assets when required, enhances planning and helps prevent costly, dangerous and all-toocommon incidents of accidental asset strikes.

The location data stored in a utility’s GIS is vital for asset management, public and workplace safety, emergency planning and response, and for maintenance activities to be undertaken efficiently and effectively.

This article presents an integrated solution, featuring handheld hardware devices capable of accurately determining the location and depth of buried utility assets, and powered by a smart mobile and cloud-based GIS, which enables an almost fully automated workflow from field to office.

UNLOCKING THE POTENTIAL OF GIS

Geographic Information Systems (GIS) are invaluable to modern utility companies. Among other things, GIS enables operators to effectively manage assets throughout their large, complex infrastructure networks so that they can continue to provide vital services to the public.

Yet to fully unlock the functional possibilities of a GIS, the spatial data detailing the location and nature of assets must be spatially accurate,

reliable and comprehensive.

Additionally, asset owners face significant challenges associated with assets that were constructed decades ago, where location data was never recorded, or was recorded inaccurately. This lack of data contributes to utilities having to spend millions of dollars each year to repair assets that are damaged through accidental excavation. This often occurs where high power or pressure assets are involved. The consequences of accidental excavation is much more than monetary costs, but lost lives as well.

Considering its importance, traditional methods of acquiring accurate asset location data are challenging, time consuming and open to error. It requires data to be handled and transcribed multiple times before being incorporated into the GIS, which creates the potential for human error.

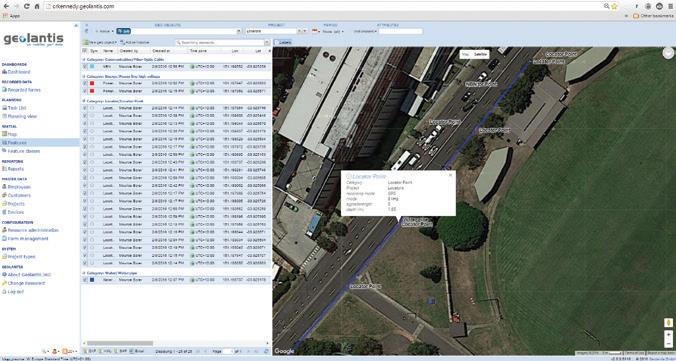

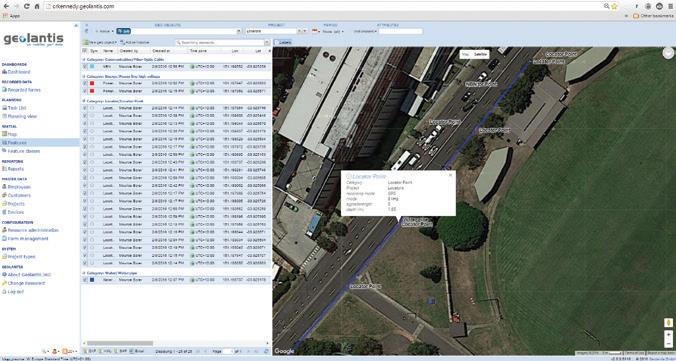

C. R. Kennedy, SmartNet Aus and Geolantis, three leading companies in the geospatial industry, have joined forces to provide a comprehensive solution for locating both above and below-ground assets with centimetre accuracy.

AN IDEAL INTEGRATED SOLUTION

The traditional workflow of asset location typically involves the field crew using utility service locators to detect underground utilities, then marking the location with spray paint and recording (often on paper) measurements such as frequency, signal strength and depth. In a separate process, a surveyor is required to accurately survey the point location. Later, the two sets of data are combined in the office and added to the asset owner’s GIS.

The solution presented by C. R. Kennedy, SmartNet Aus and Geolantis integrates the process and simultaneously captures all data digitally. This combined solution is highly accurate, data rich and provides a streamlined workflow that is substantially quicker, less costly and, most importantly, it avoids many of the opportunities for error inherent in the traditional methodology.

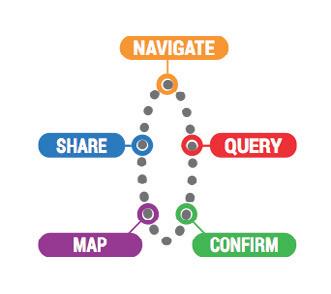

A REVOLUTIONISED WORKFLOW

The centrepiece of the solution is the mobile data collection platform. The Leica

Utility Partner Solutions MAPPING, GIS & SURVEYING 28

INSTANT MAPPING AND VISUALISATION OF UTILITY SURVEY.

Zeno 20 GNSS/GIS handheld device is an extremely accurate and intuitive data collector, which enables field users to navigate to assets easily. Its additional benefits include the ability to record various attributes about infrastructure, including technical, maintenance and condition details for each asset in customisable forms, and easy importing and exporting of shape files for processing in ArcGIS or other GIS/CAD programs.

In this integrated solution, the Zeno 20 hardware platform is powered by the cloud-based GIS software suite from European software house Geolantis GmbH. This provides a streamlined data flow, from full digital data capture in the field when an asset is located, to instant upload and display of the data in a cloudbased mapping and data management system.

Running the handheld GNSS mobile device with Geolantis’s powerful mobile application provides accurate locations against the backdrop of customer uploaded utility maps, design data, OpenStreetMap or satellite imagery, all of which provide the field operator with helpful guidance. Existing utility information can also be queried interactively via the map display to determine an underground asset’s characteristics.

Critical to the solution are the GNSS real-time kinematic (RTK) corrections provided by SmartNet Aus’ comprehensive Continuously Operating Reference Station (CORS) network, which addresses errors inherent to all GNSS satellites and thus enables centimetre accurate positioning in real-time. The SmartNet Aus base stations receive positioning signals from GPS/

GNSS satellites to calculate extremely accurate RTK corrections (down to +/- 2 centimetres) and broadcast them to GPS/ GNSS receivers.

After navigating to the recorded location of the asset, the next step involves determining and confirming the position of buried infrastructure using a subsurface service locator. The solution described supports Leica’s series of locators, including the Digicat 650i and the industry leading ULTRA model and other brands. The 650i is the ideal tool to confirm the existence of underground utility assets, while the ULTRA will enable accurate detection of both the location and depth of the assets.

Measurements from the locator are then automatically transmitted to the Zeno 20 via Bluetooth, enabling the asset information to be integrated with the GPS position and GIS feature details. The GPS position and GIS feature details are then instantly mapped on the mobile application as well as on the GIS mapping portal.

Information sharing across an organisation and beyond becomes a seamless process. The mobile software operates in online as well as offline mode and the synchronisation occurs in the background without any interruptions to the field work.

The easy-to-use online portal provided by Geolantis allows all aspects of documenting utility location tasks to be effectively managed, including personnel and equipment resource planning. The user can switch between street view, satellite imagery and cartographic street maps. Field acquired survey data is instantly available and can be accessed

by users anytime and anywhere. For areas where GPS reception is problematic or where assets are inaccessible, the Leica S910 laser distance meter can be paired with the Zeno 20 handheld GNSS device. Once combined, the platform is transformed into a remote point measurement solution, known as gamtec. This package turns the Zeno 20 into something akin to a traditional Total Station that records GIS data.

THE ADDITIONAL BENEFITS OF GOOD DATA

In addition to the previously mentioned benefits, collecting data that is comprehensive, GIS ready and as accurate as possible, also ensures usability and interoperability with other, new and future technologies. As regulations continue to tighten, ongoing adoption of best practices helps an organisation stay ahead of the curve and maintain a strong foundation for the future.

For instance, technology that allows workers in the field to visualise the positions of buried assets in 3D in an augmented reality environment is already available, and is just one of many innovations that rely on location data.

An integrated spatial data capture process, such as that provided by C. R. Kennedy, SmartNet Aus and Geolantis, can greatly improve confidence in the accuracy and completeness of spatial data. This provides a wide range of benefits, from mitigating the risks of accidental excavation, to enhancing asset management, empowering planning and preparing an organisation to take full advantage of technological innovation.

Enhancing value and confidence through accurate asset location data MAPPING, GIS & SURVEYING 30

A WELL DEFINED WORKFLOW UNDERPINS THE APPLICATION IN THE FIELD AND OFFICE.

Aqua-Assets Pty Limited

Aqua-Assets Pty Limited

Sydney: (02) 9708 0800

Newcastle: (02) 4940 0410

Email: enquiries@aquaassets.com.au www.aquaassets.com.au

Industrial Cleaning Solutions

Environmental Solutions

Emergency Response

Waste Management

• INDUSTRIAL VACUUM LOADING

• 40,000psi ULTRA HIGH PRESSURE WATER BLASTING

• COLD CUTTING & TUBE BUNDLE CLEANING

• HIGH PRESSURE WATER BLASTING

• COMBINATION – VACUUM/WATERJET

• NON-DESTRUCTIVE DIGGING

• WATERBLASTING & HYDRO DEMOLITION

• CCTV PIPELINE INSPECTION

• TRENCHLESS TECHNOLOGY

• PATCH LINING, PIPE CRACKING, CIVIL, HYDROGEN SULPHIDE, PIPELINE GAS ATTACK CONTROL

Asset Training is a Division of Aqua Assets

RTO Code: 91255

RTO Code: 91255

Email: info@assettraining.com.au

www.assettraining.com.au

HIGH PRESSURE WATER JET

• HIGH PRESSURE WATER JET OPERATOR (MSAPMWJ301A, MEM09002B, MSAPMOHS200A, MSAPMER200C, MSAPMOHS110A)

MSAPMOHS110A)

HIGH PRESSURE WATER JET ASSISTANT

• HIGH PRESSURE WATER JET ASSISTANT (MSAPMWJ201A, MSAPMOHS200A, MSAPMER200C, MSAPMOHS110A)

• CONFINED SPACE ENTRY (1 & 2 days) (RIIWHS201D, RIIWHS202D, MSAPMOHS216A, MSAPMOHS217A, MSAPMOHS200A, MSAPMPER205C)

• CONFINED SPACE REFRESHER

• CONFINED SPACE REFRESHER

• WHITE CARD General Construction Induction (CPCCOHS1001A)

• FIRST AID (HLTAID001, HLTAID002, HLTAID003)

• FIRST AID

• CPR (HLTAID001)

• WORKING SAFELY AT HEIGHTS (RIIWHS204D, RIIWHS201D)

and proud partner, Aqua Assets Pty Limited, have secured an Australian Master Agreement with Boydel Technologies for their patented Electrocoagulation / Electro Advanced Oxidisation reactor range. This technology removes the need for costly chemical, biological and mechanical pre-treatment technologies providing a single pass coagulation process to all conductive elements whilst disinfecting to 99%+ through the Fenton’s development zone of the single reactor. This technology coupled with Carbon Filtration and Reverse Osmosis will provide a fully scalable continuous flow treatment from raw sewerage to drinking water in 12 minutes.

Inovin

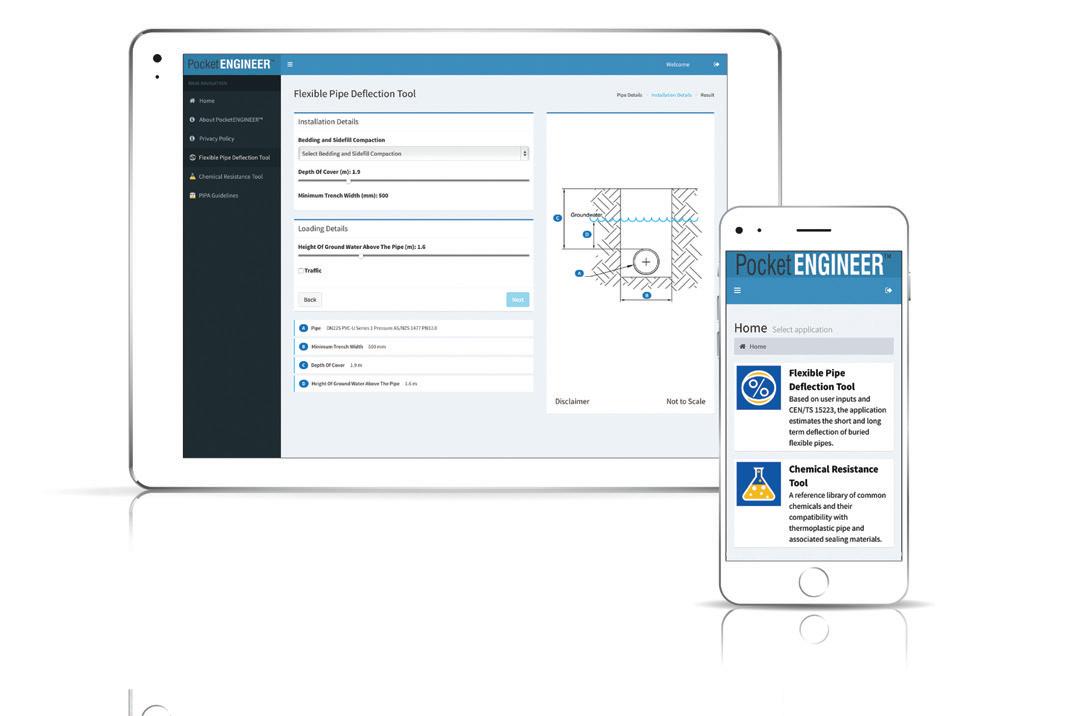

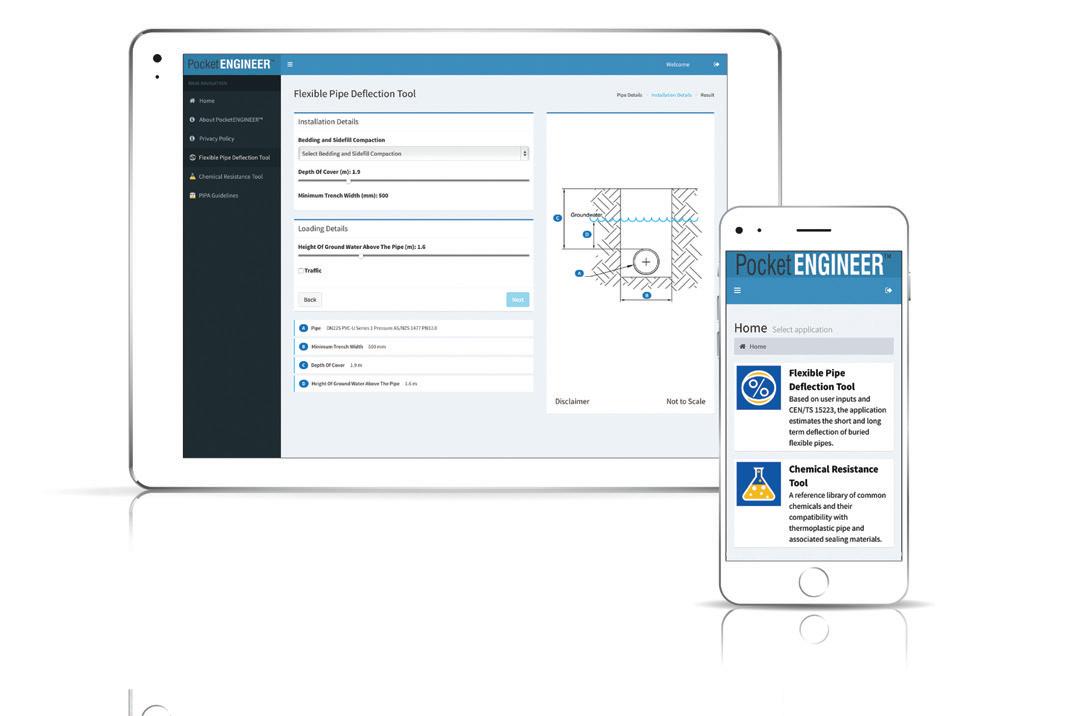

Plotting a path TO DIGITAL SUCCESS

by Kevin Hutchings, Managing Director, South East Water

The water industry has many individual examples of digital technologies delivering more sustainable, cost-effective and flexible water solutions for customers, but its overall adoption of emerging technologies could be greater. Engagement, collaboration and a bold mindset are essential if the water industry is to take full advantage of the next wave of opportunity technology is creating.

SMART METERS

SMART METERS 33

f we had the technology to deliver more flexibility and cost savings to water customers, increased asset utilisation for water authorities, and a reduced impact on the environment, we’d jump on it, right?

I’d like to think so. But despite the advances we’ve made in communications, battery technology and analytics, the water industry’s adoption of emerging technologies could be greater. Today I want to call out the technologies that are already unlocking value across the water supply chain, and identify the key ingredients for their successful, industry-wide adoption.

The fact is, we already have technology embedded in our networks that is producing huge volumes of data across a range of indicators, including water quality, pressure, and wastewater flows. However, we are only just beginning to harness the value of this data.

Technology isn’t the only driver of change – customer expectations, government policy and regulation, competition and economic climate all have a major influence – but we mustn’t lose sight of the opportunities before us.

When Sir Joseph William Bazalgette convinced authorities in 19th century London that a gravity sewer system was the only way to tackle the capital’s ‘Great Stink’, he established the design standard for urban sewer systems that is still upheld today.

Gravity has served us well, but technology now exists that can completely transform the way we manage wastewater, with benefits across the board. Let me give you an example.

South East Water is currently connecting 16,500 homes on the Mornington Peninsula with a pressure sewer system. At each property, the septic tank is replaced with an 850-litre storage tank and pump, which discharges into a pressured sewer network.

The system is built around an intelligent, SCADA-connected system

designed by South East Water called OneBox, in which each property’s sewer connection is remotely managed on a real-time basis, depending on a range of local and network factors.

The benefits to South East Water as the asset owner are huge. Because we can regulate flows of waste into the network, we can remove diurnal peaks and reduce the size of the infrastructure needed to transport and process the wastewater. For example, the reticulated network is made up of pipes with an internal diameter of just 63mm. Without the need for trenches and manholes, construction costs are slashed, and occupational health and safety risks involved in system maintenance are dramatically reduced.

What’s more, we’re able to monitor for illegal connections, inappropriate waste disposal, and water leaks such as leaking toilet cisterns. And that’s where the customer really benefits.

Last month our operations team picked up a continuously running wastewater pump at a customer property, a holiday home. Real-time data from the pump, which was transmitted back to South East Water on a second-by-second basis, suggested a water leak on the property, and we were able to notify the owners before damage occurred, and without significant impact on the water bill.

The environmental benefits have been significant also. The pressure sewer scheme’s smaller specifications

enabled the use of horizontal directional drilling (HDD) during installation, which minimised surface disturbance in what is recognised as an environmentally sensitive area. In addition, the low pressure network design reduced the number of power hungry and expensive transfer main pumping stations from seven to two.

The benefits are clear and wideranging, but how do we extend technology such as this more broadly across our industry, so that more customers can benefit?

To make progress, I believe there are three critical success factors: community engagement, collaboration, and a bold mindset.

Within our industry, many of us have long recognised the benefits in digitising and automating our water networks, but what of our customers and other stakeholders? Where do their interests lie? How can technology help to meet their needs? And how can we engage with them to demonstrate the value of digitising the network?

A key element in South East Water’s customer assistance program is the water audit, in which we supply customers experiencing financial stress with a handheld device that enables them to monitor water usage in real-time and receive alerts when daily water usage targets are reached.

Over summer, an elderly couple in Melbourne’s south east successfully used the device to make a number of behaviour changes, such as shorter showers, less hose-watering and fewer washing loads. The result was a reduction of $900 from their annual water bill and unsurprisingly, the couple are reluctant to return the device to South East Water. How many others would jump at the same opportunity to better manage water usage?

Planners and policymakers also have much to gain through network digitisation. By digitising our networks, we can make better decisions, more quickly, about how water is managed across a population.

Again, a real-world example. Together with Yarra Valley Water and City West

I

SMART METERS 34

a path to digital success

KEVIN HUTCHINGS.

Plotting