STORAGE SUPERCHARGES AUSTRALIA’S UPTAKE OF RENEWABLES SAFEGUARDING OUR WATER SUPPLY THE TECHNOLOGY TRANSFORMATION Engineering, Construction & Maintenance www.utilitymagazine.com.au Issue #22, May 2019 WATER SEWER ELECTRICITY GAS

Australia has just sweltered through its hottest summer on record, and prolonged drought conditions continue across the country, with the eastern states most affected.

According to climatologists at the Bureau of Meteorology, summers like this are only going to become more common. Low levels of rainfall, along with increasing demand as a result of population growth, will have significant implications for our water storages.

During the 2018/19 summer, South East Queensland’s bulk water authority, Seqwater, saw water use reach its highest levels since the Millennium Drought. It has developed a Water Future Program to increase community understanding of the water cycle — how water is sourced, stored, treated and supplied — and encourage people to see it as a precious resource all year round.

Community education is vital for improving water efficiency, but it is only one aspect of ensuring long-term water security. As we discovered in our interview with Professor Zhiguo Yuan, Director of the Advanced Water Management Centre, alternative water sources and decentralised business models are key components of integrated water management, an approach that could solve the water security challenge.

The extreme weather events of the 2018/19 summer also impacted the energy sector, with bushfires, floods and cyclones all wreaking havoc on the nation’s networks. This did not stop 2018 being a remarkable year for the clean energy industry however, with clean energy contributing 21.3 per cent of Australia's total electricity generation.

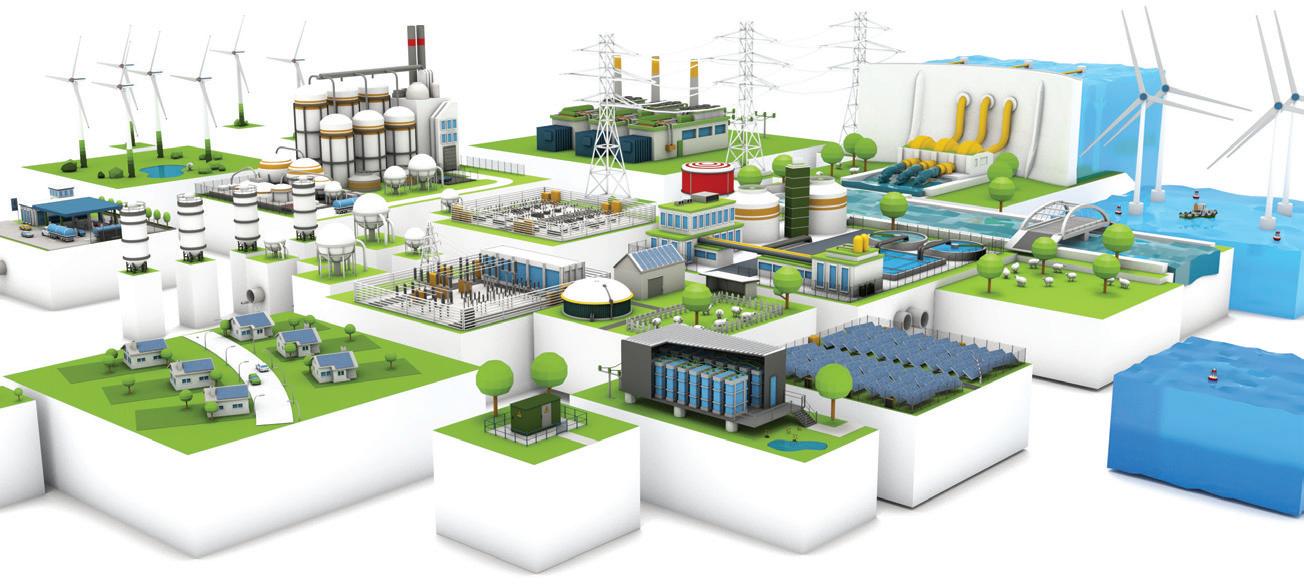

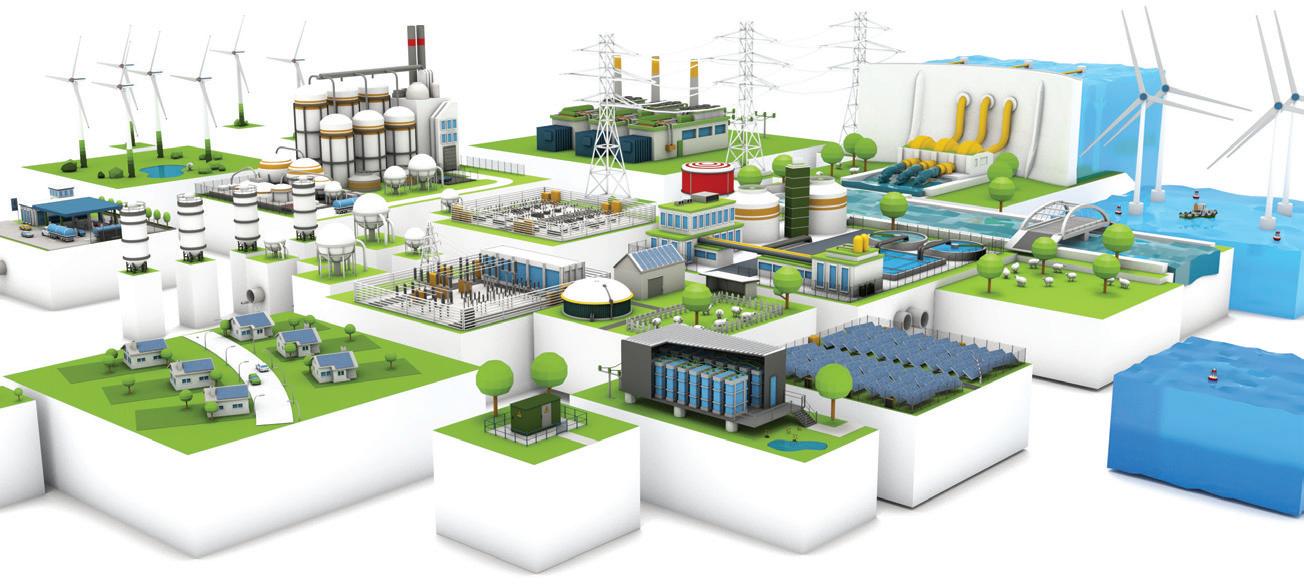

In an energy system increasingly powered by renewables, flexible capacity technologies, together with demand response, will be key to providing secure and reliable electricity. Large-scale energy storage, including utility-scale battery storage and pumped hydro energy storage, are two examples of flexible technologies helping to balance the grid, and in this issue we take a look at the main storage projects and strategies being undertaken in each state.

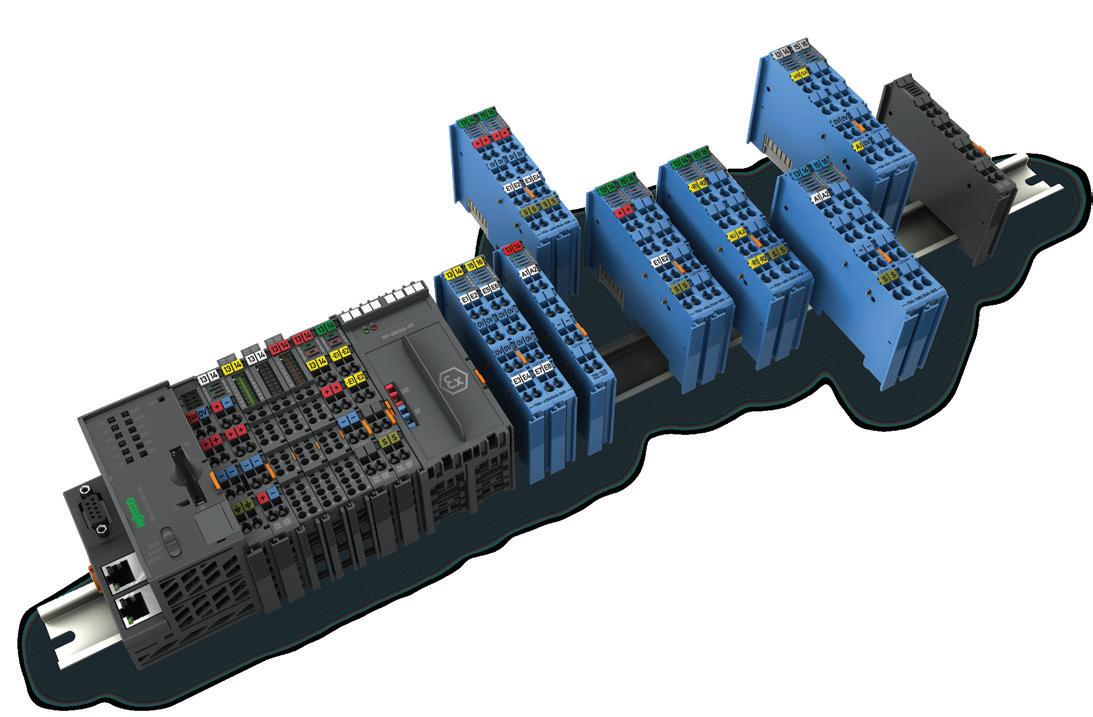

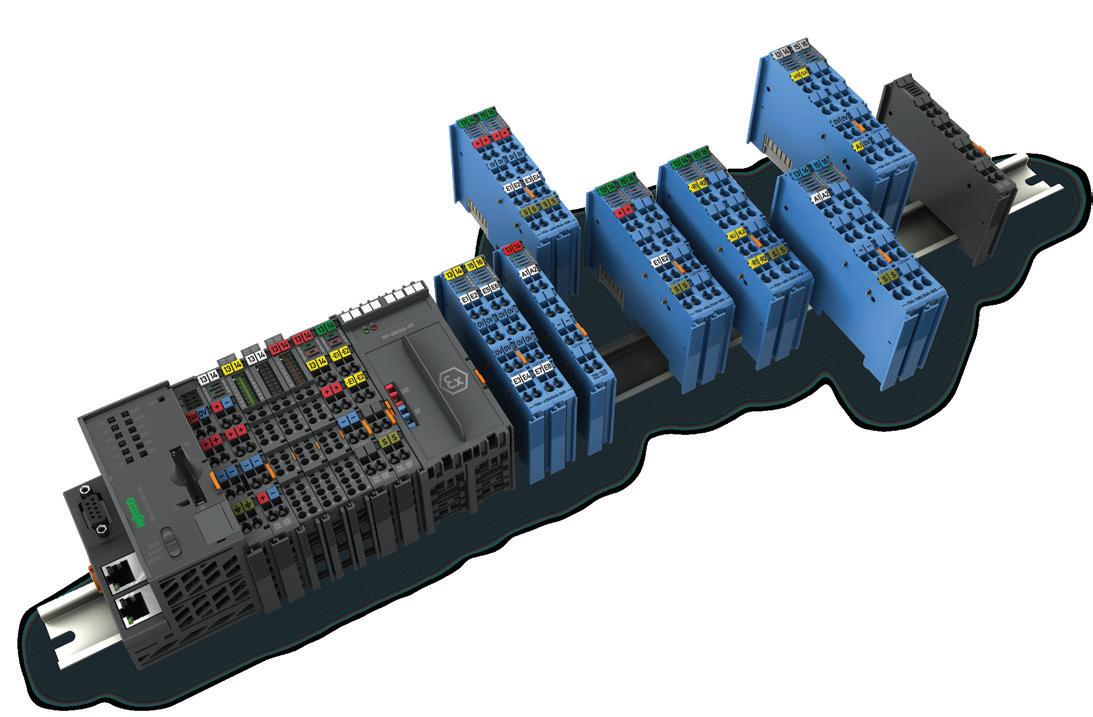

Technology transformation is also essential in building the grid of the future. The University of Western Australia (UWA) is one of six universities to be selected

for a national program, Industry 4.0 Testlab, that will work with industry to develop new technologies as part of the fourth industrial revolution (known as Industry 4.0). The Industry 4.0 Testlabs will showcase technologies such as advanced automation and robotics, machine-to-machine communication and sensor technology.

One of the themes of our recent event, Digital Utilities 2019, was emerging technologies. Utility hosted over 200 delegates from Australia’s major water and energy utilities and there were some fascinating discussions about how we can use digital technologies to optimise asset management, improve network operations and keep up with changing customer demands. My key takeaway from the conference was less about technology and more about people however; innovation comes from investing in people and creating the right culture. The event was a huge success and I am already thinking of ways to make 2020 the best yet!

As soon as one event ends, another begins, and we’re excited to launch the inaugural Smart Cities conference, which is taking place from 30–31 May in Melbourne. It is a two-day event that brings together the pillars of our cities –representatives from the buildings, roads, transport and utility industries – to educate you on the latest developments that are making our cities smarter, and provide opportunities for collaboration to maximise the interoperability of new technologies across different industries.

Asset Management for Critical Infrastructure is also returning for its third year, and is the place to be for updates on technologies, projects and processes that help to better manage critical assets in Australia, from water pipes and energy networks to railways. The event will be held from 21-22 August and you can join our pre-sale at assetmanagementevent. com.au.

I hope to see you at one of these events and as always, I am keen to hear your thoughts and feedback on Utility, so feel free to drop me a line at charlotte. pordage@monkeymedia.net.au.

Charlotte Pordage Editor

UTILITY • MAY 2019 Published by Cover A image highlights our feature on water management. Cover B image highlights our feature on energy storage. Engineering, Construction & Maintenance www.utilitymagazine.com.au Issue #22, May 2019 STORAGE SUPERCHARGES AUSTRALIA’S UPTAKE OF RENEWABLES SAFEGUARDING OUR WATER SUPPLY INDUSTRY 4.0: THE TECHNOLOGY TRANSFORMATION STORAGE SUPERCHARGES AUSTRALIA’S UPTAKE OF RENEWABLES SAFEGUARDING OUR WATER SUPPLY THE TECHNOLOGY TRANSFORMATION durable Peak/ UNDERGROUND LOCATING www.utilitymagazine.com.au Issue #22, May 2019 Monkey Media Enterprises ABN: 36 426 734 954 204/23–25 Gipps St Collingwood VIC 3066 P: (03) 9988 4950 monkeymedia.com.au info@monkeymedia.com.au utilitymagazine.com.au info@utilitymagazine.com.au ISSN: 2203-2797 Editor Charlotte Pordage Assistant Editor Lauren 'LJ' Butler Journalist Siobhan Day Senior Designer Alejandro Molano Designers Jacqueline Buckmaster Danielle Harris Business Development Manager Rima Munafo Publisher Chris Bland Managing Editor Laura Harvey Operations Manager Kirsty Hutton Digital Marketing Manager Sam Penny 8,138 This publication has been independently audited under the AMAA’s CAB Total Distribution Audit. Audit Period: 1 April – 30 September 2018 FROM

EDITOR welcome May 2019

THE

ISSUE 22 1

2

UTILITY • MAY 2019 WWW.UTILITYMAGAZINE.COM.AU 46 36 58 WATER MANAGEMENT Water management of the highest order 28 In January 2019, Professor Zhiguo Yuan, Director of The University of Queensland’s Advanced Water Management Centre, was appointed as a Member of the Order of Australia. This award recognises his significant service to science through urban water management, and to higher education. Utility Editor, Charlotte Pordage, caught up with him to learn more about one of Australia’s most esteemed engineers. Filtec and Practical Filtration Solutions: making water safer – together .......................... 31 Enhanced stormwater monitoring 32 Australian steel facilitates construction of W2BH pipeline 34 Managing water demand in South East Queensland 36 Expanding capabilities for HDPE pipe 40 Hunter Water to implement proven energy solution .............. 42 Pumping pools into pristine condition 43 ENERGY NETWORKS May the fourth (industrial revolution) be with you .............. 58 Going underground: Relocating circuits under Melbourne’s busiest road 62 Creating new, connected consumer experiences in the Australian energy sector 64 Connecting the dots on customer experience 66 VEGETATION MANAGEMENT Working to improve vegetation clearance outcomes near powerlines 96 Weeding out glyphosate in vegetation management 101 UTILITY LOCATION The advance of utility locator technology 94 WASTEWATER MANAGEMENT The challenges of century-old sewer renewal ............................. 44 Building a smart wastewater network 46 Swift and smart sewer system renovation 50 When to select a centre-flow or through-flow band screen.......... 52 IRRIGATION The Murray-Darling Basin Royal Commission Report: key findings, recommendations and responses 54 72 72 96 94

CONTENTS

May 2019 ISSUE 17 3 UTILITY • MAY 2019 WWW.UTILITYMAGAZINE.COM.AU 68 DEMAND MANAGEMENT Exploring non-network solutions to manage electricity demand 68 ENERGY STORAGE The top energy storage initiatives Down Under 72 76 84 SMART METERS Digital data pays off for Energy Savvy Families 76 Taggle's proven smart water networks are rolling out across the country 78 MOBILITY Making real-time asset management a reality 80 The ICurve ................................... 82 Driving the digital workforce 84 Optimising your IT investment .. 86 INSPECTION Modernising GIS for a fully connected network ............. 88 Rise of the machines: drone inspections take off 90 Safely storing Melbourne’s most valuable resource 92 In each issue Welcome from the Editor ���������������������������������������������������������������������������� 1 A word from Energy Networks Australia��������������������������������������������������4 A word from WSAA ������������������������������������������������������������������������������������� 6 News briefs �������������������������������������������������������������������������������������������������� 8 Advertisers’ index ����������������������������������������������������������������������������������� 104 Editorial schedule ����������������������������������������������������������������������������������� 104 102 The utility industry is regularly required to call on an enormous and varied range of specialists; from mapping, to drilling, to wastewater treatment, to asset management, to pipe relining, to pipeline integrity, to land access, to risk management, and the list goes on. To make the process a little easier, Utility is bringing together experts from various fields to answer your questions. i

A WORD FROM ENERGY NETWORKS AUSTRALIA

ANDREW DILLON CHIEF EXECUTIVE OFFICER – ENERGY NETWORKS AUSTRALIA

With six solar panels installed on Australian homes every minute and household solar policies the focus of political debates, there is an increasingly urgent need for consistent connection guidelines.

That is why Energy Networks Australia has developed the first set of guidelines for safe, consistent and efficient installations of solar, storage and battery devices to the grid.

THE ISSUE

Household photo-voltaic solar systems and other distributed energy resources (DER) offer customers greater choice and control over their energy use. Their uptake is strongly supported by energy networks, but they can present significant challenges that impact the performance of the electricity grid. Because of this, customers need to obtain approval from their electricity distributor to connect their systems.

A network connection agreement must be lodged and approved by the electricity distributor before systems can be installed.

This agreement sets out the terms and conditions of grid connection, including the size and type of the system and technical requirements that must be met.

To date, distribution network providers have developed their own connection processes to ensure the delivery of safe and reliable electricity to customers. These have been influenced by their own unique mix of customers, geographic conditions and business models, all operating under a sophisticated set of rules, regulations and performance criteria.

The result is a diverse landscape with a range of technical requirements and connection processes. While these connection processes are consistent with the National Electricity Rules, inconsistencies between networks, combined with complicated processes and a perceived lack of transparency, have led to frustration for the entire supply chain and its customers, with connection delays and extra costs.

THE SOLUTION

To address these issues, Energy Networks Australia, supported by all the electricity distribution networks across Australia, started a project in early 2018 to standardise the connection of DER into the grid.

Every customer’s needs are different and the generation potential of solar power differs from place to place, so solar and battery systems will differ. What doesn’t change, however, is the need for maximum efficiency, lowest cost and steady electricity supply, which is what the guidelines will support.

The project developed a suite of national guidelines to facilitate safe, consistent and efficient grid connections, mitigate potential risks and help reduce costs to networks and customers. The guidelines streamline the technical requirements for the network connection of a range of generation technologies and will be used by network companies as a template to develop their own.

THE TECHNICAL GUIDELINES

The first two technical guidelines, Technical Guidelines for Basic Micro EG Connections and Technical Guidelines for Low Voltage EG Connections, were released in March 2019. These address low voltage connections for household, commercial and industrial premises. They articulate the structure, definitions and technical settings distribution networks should adopt in the development and application of their technical requirements for grid connection of DER. They also outline the relevant rules, regulations, standards and codes, along with testing, commissioning, operations and maintenance requirements.

While compliance with these guidelines is not mandatory, all the relevant networks have committed to adopting the requirements and agreed to participate in annual compliance reviews, including independent assessments.

Work is underway to produce the next set of guidelines to address medium and high voltage connections within the distribution system. These guidelines are expected to be released later this year.

Australia’s embrace of global energy transformation is world-leading when it comes to the adoption of household solar and storage. Customers like being in control of their energy, however the speed of this change has taken everyone by surprise. The energy network sector is working hard to ensure Australia’s grid and any associated outdated processes are modernised to enable this revolution.

UTILITY • MAY 2019 WWW.UTILITYMAGAZINE.COM.AU 4

integrity {in•teg•ri•ty}

noun. The quality of being honest and having strong moral principles. Complete harmony in what one thinks, says, and does.

synonyms: strength, honour, cohesion, undividedness

collaboration {col•lab•o•ra•tion}

noun. The action of two or more people or organisations working towards a common goal. A focused effort to accomplish a task or project together.

synonyms: cooperation, partnership, participation

innovation {in•no•va•tion}

noun. The introduction of new things, ideas or ways of doing something that can create value and/or gain a competitive advantage.

synonyms: change, revolution, break with tradition

Comdain delivers quality engineering and asset management services to Australia's leading utilities and energy providers and it has been that way for over 50 years. We approach everything we do with integrity and an unwavering commitment to collaboration and innovation.

COLLABORATION INNOVATION

comdaininfrastructure.com.au INTEGRITY

A WORD FROM WSAA

This issue, WSAA would like to highlight its Young Utility Leaders program, with Adam Lovell, Executive Director at WSAA, commenting, “I’m really proud of WSAA’s Young Utility Leaders personal development program. Now in its second year, we have engaged with young leaders in our membership and provided them with development opportunities. Two of the young leaders, Anna Reeves from Coliban Water and Morgan Pauly from Sydney Water, attended recent WSAA events and sought advice on leadership from the speakers they heard. Here’s what they learnt.”

We have had the privilege of listening and learning from leaders at the very top of our industry. In February, we witnessed a fireside chat with Liv Garfield, Chief Executive of Severn Trent Water in the UK. Liv energetically and expertly navigated topics on everything from the challenges for low socio-economic customers, to leak management through to customer expectations. We asked Liv what qualities she looks for in a future leader?

“Self awareness is the most important quality as it allows you to develop faster. Will over skill – the right attitude, the right work ethic and the right enthusiasm. Curiosity – only through truly understanding new things can you develop and the most curious of minds tend to understand more,” she said.

We also heard from a range of speakers at the WSAA Members Meeting, which covered the challenges impacting our communities in the near and distant future. But as we know, with challenge comes opportunity if you look in the right places.

“The key challenge is figuring out how to source water to sustain future growth. Water utilities can’t walk past this challenge given the effects of climate change,” Amanda Jones, COO and Deputy CEO, Infrastructure NSW, said. Sarah Hill, CEO of the Greater Sydney Commission, also detailed the vision to shape metropolitan planning through regional and district plans in greater Sydney. One of the key themes woven through the vision is water.

“Water is fundamental to Greater Sydney’s resilience and sustainability, so there are tremendous opportunities for young leaders in the water sector to play a crucial role in Greater Sydney’s future,” Sarah Hill said.

If we start with water, preserve the green spaces, overlay the infrastructure and introduce integrated landscape and urban design, we have a blank canvas to shape a livable, productive and sustainable community.

The changing approach to planning means the role of the modern water utility is also changing. Delivering this vision means place-based outcomes will be key, delivered through collaboration across government departments, agencies and organisations.

This means a shift in mindset. Water has often been an afterthought in the planning process, but if we want to create truly water sensitive cities that are resilient and liveable, water must be an integral part of the planning process – right from the start!

So with these big picture challenges ahead of us, what is the role of Young Utility Leaders in the urban water industry?

“Put your hand up and get involved! At a personal level, I encourage you to be proactive in finding solutions, not just citing the problems or being deterred at barriers to progress,” Sarah said.

“Success doesn’t come to those who are the brightest, but comes to those who are most resilient, lead teams better than others and create their own luck through hard work,” Liv said.

“Be kind – it costs nothing, and you never know where or when you might meet that person again,” Amanda said.

Finally, we reached out to Kevin Young, Managing Director at Sydney Water. Kevin said, “The future is all about leadership and doing water differently and better.

“Have courage and say yes a lot, even if you are not sure if you have the skills and experience. Build your security and confidence through your performance. Put yourself to the test, and take on challenging and difficult jobs. Success breeds success — even if you fail at something reflect on what you have learned and this will also breed future success. As Michael Jordan famously said, ‘You miss every basket you decide not to take a shot at!’”

UTILITY • MAY 2019 WWW.UTILITYMAGAZINE.COM.AU

6

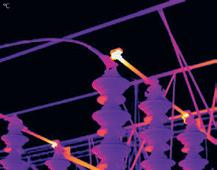

Madison Technologies Understands IEC 61850

Whether you’re looking to retrofit an existing substation, or build a new one from the ground up, the advantages of implementing the IEC 61850 standard are the same; simplified architecture, greater reliability, future-proof design and vendor Independence. Our team understand critical power applications, and can work with you to find the best solutions from the comprehensive Moxa range.

Incorporate

IEC 61850 range of computing and communications devices in critial power applications. End-to-End PRP/HSR Solutions for substation automation and feeder automation applications, for both public utilities and enterprises.

IEC 61850, IEEE 1588, and PRP/ HSR compliant solutions 9 Fully integrated IEC 61850 MMS solution consisting of Ethernet switches, device servers, converters and embedded computers 9 Supports GOOSE, MMS, SMV, PTP and other mission critical protocols 9 Devices that can withstand harsh operating temperatures in mission critical environments 9 “Bumpless”, Zero recovery time Make substations smarter with IEC 61850

Moxa’s

9

Contact us on 1800 72 79 79 or email moxa@madisontech.com.au with

Madison, you’re

NEW MACHINE LEARNING TOOL TO PREDICT SEWAGE OVERFLOWS

Anew piece of software will use machine learning to predict sewage overflows, and potentially avoid overflows entirely.

Unitywater and GHD have developed the sewer overflow prediction tool.

Unitywater Manager, Asset Knowledge and Performance, Ivan Beirne, said the tool was a win for the environment and the utility.

“While this tool is still in the testing phase, it has demonstrated the ability to accurately predict wet weather impacts faster than previous hydraulic models used to predict sewage overflows.

“Sewage overflows are priority one jobs, which must be responded to within one hour and can pull our field crews away from other planned work. If we can predict sewage overflows and manage our network accordingly, we can avoid diverting crews to these jobs and this is really beneficial for us,”

he said.

Mr Beirne said the tool used radar precipitation echo images, and harnessed the relationship between rainfall patterns over time with sewer overflow events.

He said it consisted of two machine learning components, a radar echo ‘nowcasting’ model and a sewer overflow prediction model.

The ‘nowcasting’ model produces short term (0-6 hour) rainfall radar image forecasts using the previous two hours of rainfall obtained from the Bureau of Meteorology (BOM) and the overflow model then predicts the likelihood of a sewage pump station overflow.

“Once used operationally, the model will feed live rainfall radar data from BOM to produce overflow risk scores,” Mr Beirne said.

“We can then determine those pump stations most at risk and take

preventative action.”

GHD Digital Solutions Lead (Water and Innovation) and Director Digital Labs, Saskya Hunter, said, “Working on this project with Unitywater has been extremely valuable, both in terms of the digital nature of the solution that has been developed and the opportunity to explore new ways of working through AquaLAB — our co-creation program for the water industry.

“We are excited by the promise that the prediction tool shows, and the broader benefits that it may provide to the environment and the water industry.

“GHD Digital is working hard to make co-creation a reality through our AquaLAB initiative, and we are pleased that Unitywater has been prepared to come on the journey with us for our pilot project,” she said.

The project was a finalist in the 2019 Digital Utility Awards.

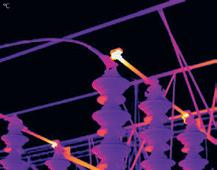

ARC FLASH MITIGATION

UTILITY • MAY 2019 WWW.UTILITYMAGAZINE.COM.AU NEWS 8 Arc Flash Protection PGR-8800 Ultra Fast (<1msec) light detecting relay to minimize Arc Fault damage to plant and personnel. Neutral Earthing Resistor SE-330AU

leading relay that continually monitors integrity of Neutral Earthing Resistors. 6/8 Selkirk Drive, Noosaville, QLD 4566 P.O. Box 1965, Noosaville, QLD 4566 T 07 5455 5060 | F 07 5455 5062 E sales@startco.com.au www.startco.com.au Representing Littelfuse Inc Australia & New Zealand.

Industry

PROTECT YOUR PLANT & PERSONNEL

AUSTRALIA’S FIRST THERMAL WASTE-TO-ENERGY FACILITY UNDERWAY

Construction has commenced on Australia’s first thermal wasteto-energy facility, which is expected to reduce landfill by 400,000 tonnes of waste.

The facility, named Avertas Energy, will contribute to landfill reduction by diverting waste from landfill, reducing carbon dioxide emissions by the equivalent of taking 85,000 cars off Perth’s roads.

In addition, Avertas Energy will generate and export 36MW of green electricity to the local grid per year, sufficient to power more than 50,000 households.

Scheduled to open in 2021, Avertas Energy already has 20-year waste supply agreements in place with Rivers Regional Council and the City of Kwinana, playing a role in supporting those local governments’ waste management strategies. As

the preferred supplier of baseload renewable energy, Avertas Energy will also be supporting the green energy needs of the Western Australia Local Government Association (WALGA) and its members.

Although new to Australia, thermal waste-to-energy has a long track record internationally. Avertas Energy is implementing moving grate technology, which is used in approximately 2000 facilities globally. In other countries, waste-to-energy is part of an overall solution for reducing landfill in conjunction with avoiding waste production, recycling and reuse. Waste managed by Avertas Energy will result in recovery of metallic materials that will be recycled and by-products that will be reused as construction materials.

More than 800 jobs will be created over the course of the construction

period and more than 60 new full-time positions once the facility is operating. Acciona, which has been appointed to build the facility, has begun engaging with local sub-contractors about opportunities during construction. Postconstruction, Veolia ANZ will operate and maintain the facility for 25 years.

Premier of Western Australia, Mark McGowan, said, “Western Australia is at the forefront of new technologies for the management of waste and the reliable generation of new sources of energy.

“Pressure on landfill is a concern for communities around the world and Western Australia is taking a leadership position in Australia by embracing new methods and technologies that can sit alongside other strategies for managing waste over the long term.”

UTILITY • MAY 2019 WWW.UTILITYMAGAZINE.COM.AU NEWS 10 AUST RAL I A WI DE · COMMUNI CAT I ON & POWERL I NE · AUST RAL I AN MADE WWW FUTUREAU COM AU SALES@FUTUREAU.COM.AU +61 8 9417 4999 Lattice Towers Steel Monopoles PLS-CADD powerline profiling Design and install foundations Conductor and OPGW stringing Underground cable installation Fibre optic cable installation Transformer compounds Testing and commissioning

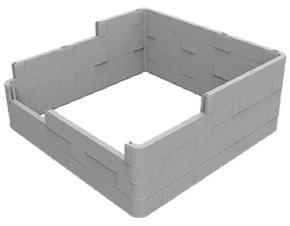

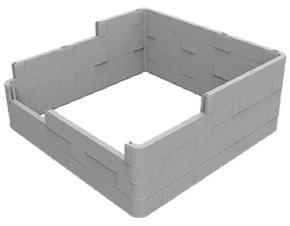

PIT INNOVATION FOR WATER AND ENERGY SOLUTIONS

Working in water and energy requires structurally robust and easy to install pits to ensure each project’s success. Delivery of the Nambucca Shire Council and NSW CBD Electrical Services Relocation Projects saw the installation of the STAKKAbox ULTIMA, Australia's first high-strength modular access pit system.

Nambucca Shire Council required flow meter installation on two existing trunk mains to monitor water flow to the Shire water distribution system and leakage in the trunk mains. The need to turn off water supply or physically cut piping during the installation process was eliminated due to the robust strength, installation and customisation capabilities offered by the innovative STAKKAbox ULTIMA Connect pit system.

Traditional methods risked compromising the integrity of the existing AC pipes’ integrity. STAKKAbox access pits were rapidly assembled around existing pipes without requiring third party contractors or additional plant hire. Clean entry and exit points for piping were created as the ULTIMA pits were assembled using standard cutting tools and a rubber mallet.

A key priority was ensuring the protection of the new Ultrasonic Flow Metre equipment being installed on the pipeline so that its electronic components weren’t directly exposed to the possibility of moisture damage. Design specifications required a minimum Class B pit load capacity, yet the ULTIMA’s impressive Class D strength properties offered increased security and prolonged life-span benefits for the asset’s electrical components and the overall system.

Another stellar example of the STAKKAbox ULTIMA system’s installation flexibility and timeliness was the relocation of vital electrical services located along Pitt Street in Sydney’s Central Business District. The STAKKAbox ULTIMA Hybrid provided a customised underground network access solution that accommodated existing services without specialist resources.

The heavily congested business district location of the site meant that elimination of any possible public safety risks underpinned all aspects of the installation. The lightweight, modular structure of the STAKKAbox allowed rapid simultaneous installation of both jointing bays, thereby minimising risks and enabling any adaptations required to support existing services to be easily made on site during assembly.

Both the aforementioned water and energy projects were installed within hours without the requirement of specialist builders or tooling, reducing associated health and safety risks while also providing impressive savings to both the asset owners and major contractors. By reducing freight costs and labour expenses, and exceeding safety standards, the STAKKAbox ULTIMA system is a key solution for a range of utility industry needs.

Reduces

UTILITY • MAY 2019 WWW.UTILITYMAGAZINE.COM.AU 11

NEWS Utility Partner Solutions www.cubis-systems.com.au Ph: 1800 065 356 FAST AND EASY TO INSTALL Providing substantial cost reductions. SMOOTH OUTER WALLS WITH LIP TO ‘KEY IN’ ULTIMA beams ensure all pieces are flush and no movement occurs once assembled. FLEXIBILITY IN CONSTRUCTION Variable wall section lengths enable pit customisation. ULTIMA pit systems can be built over existing infrastructure. Duct entries can be formed on site with standard hand/power tools. SECTIONAL AND TWIN WALL DESIGN Lightweight sections can be manually lifted. A vertically strong product that can be built to variable depth requirements. VARIABILITY IN SIZE

a large number and variety of standard sections, ULTIMA allows for construction of virtually any pit size.

PACK ARRANGEMENT

With

FLAT

freight

STRENGTH CAPABILITIES

Class D load capacity without requiring specialist bracing, backfilling or concrete surrounds.

costs and allows for delivery and installation flexibility. ROBUST

Achieves

NEW VIRTUAL POWER PLANT FOR NSW

Ausgrid and distributed energy leader, Reposit Power, have launched a 1MW virtual power plant (VPP) for 233 customers across Sydney, the Central Coast and the Hunter region.

Customers who choose to participate in the trial, which allows electricity from their batteries to be directed back into the grid, will receive direct cash payments from Ausgrid, through Reposit Power, of up to $135 per year, depending on the size of their battery system.

When Ausgrid activates signals to customers’ batteries via the customer’s Reposit software, their stored energy is exported to the grid. Reposit then pays customers for the energy they supply, lowering their energy costs.

Ausgrid CEO, Richard Gross, said the trial is being delivered by Ausgrid’s Power2U initiative, which is part of a broader $7 million demand management innovation program. He said it is one way Ausgrid is engaging with partners and customers to shape the future of energy, by working smarter with the customers’ existing renewable energy investments.

“This is the first program of its type for Ausgrid. Solutions like a virtual power plant not only help customers, it helps the grid. If the trial is successful, it could provide a lower cost alternative to grid investment, which would result in lower customer bills in the long term,” Mr Gross said.

“The partnership with Reposit Power will give our customers a choice about the way they share their excess

electricity and gives them a better return on their investment.

“We will continue to explore alternative ways to deliver more flexible grid services to our customers to reduce their electricity costs and the costs on our network.”

Reposit Power co-founder and CEO, Dean Spaccavento, said that the future of energy is happening now, and Australia is leading the charge.

“Reposit Power is proud to partner with progressive energy companies like Ausgrid and share their passion for empowering consumers and communities,” Mr Spaccavento said.

“Reposit was recently awarded the highest engineering award for building a Virtual Power Plant (VPP). VPPs are the next step in Australia’s energy revolution.

“We are confident that this trial will demonstrate the value of our clean, flexible and cost effective VPPs to individual households and the wider community.”

The partnership with Reposit is the first stage of Ausgrid’s VPP program. To enable greater customer choice and expand the VPP, Ausgrid will invite participation from other demand response market providers later this year. Customers can also register their interest with Ausgrid to receive updates on the progress of VPP.

For more on Ausgrid’s Power2U program, visit https://www.ausgrid.com.au/vpp.

UTILITY • MAY 2019 WWW.UTILITYMAGAZINE.COM.AU NEWS 12 Unit 2 / 85 Heatherdale Road, Ringwood Vic 3134 PO Box 2500, North Ringwood Vic 3134 P: (03) 9872 4596 | F: (03) 9872 3293 | E: info@pezztrenchless.com.au Still the market leaders in laser guided microtunnelling Bore diameters from 325mm up to 2800mm Used for gravity sewers, water mains, storm water, gas and electrical conduits. Specialists in “free bore”, sleeve boring and pipe jacking in all sizes The Next Generation in Trenchless Technology

Innovation reduces your Arc Flash incident levels

The consequences of an arc flash can include significant damage to switchgear, conductors and the switchboard. The worst consequence of such electrical faults is the injury or death of electrical maintenance staff who frequently work within electrical switchrooms.

To help reduce the effects of a low voltage switchboard arc flash, NHP and Terasaki have developed the Arc LogiX system. This system uses the concept of ‘active circuit breaker suppression’. Potential arc flash incident energy is reduced by automatically adjusting down the short circuit protection settings of the incoming Air Circuit Breakers (ACBs).

The Arc LogiX system utilises the Terasaki TemPower 2 ACB which can clear a short circuit fault in less than 30ms thanks to its patented double break contact design. 30ms is the fastest total short circuit clearance time available from any ACB on the market today.

For more information, visit nhp.com.au/more/arclogix

NHP ELECTRICAL ENGINEERING PRODUCTS

1300 NHP NHP | nhp.com.au

NHP107238 11/18

|

MAJOR WATER UTILITY RELEASES RECONCILIATION ACTION PLAN

The Water Corporation has been congratulated on its launch of the 2019-21 Reconciliation Action Plan (RAP), which seeks to address social and economic disadvantage amongst Aboriginal and Torres Strait Islander people in Western Australia.

The fifth RAP released since 2008 challenges previous targets to help achieve the State Government’s vision for

sustainable outcomes in employment, education, business and procurement opportunities.

In a nation where Aboriginal and Torres Strait Islander people are three times more likely to be out of work, WA’s public water utility has pledged to employ a workforce that is representative of the entire Western Australian community.

Exceeding its 2018 Aboriginal and Torres Strait Islander

14 UTILITY • MAY 2019 WWW.UTILITYMAGAZINE.COM.AU NEWS NSW Ph: 02 8197 2825 WA Ph: 08 9201 0948 QLD Ph: 07 3333 2825 SA Ph: 03 9017 8225 Head Office: Unit 20, 51 Kalman Drv Boronia VIC 3155 Ph: 03 9017 8225 Fax: 03 9729 9604 www.ams-ic.com.au sales@ams-ic.com.au AMS Instrumentation & Calibration Pty Ltd Analytical Process Division Oxygen Analysers, Thermal Conductivity Analysers, NDIR Analysers, Multigas Analysers, OEM Analysers U.V Absorption Conductivity pH / ORP Colour Industrial Water Analysers and Liquid Analytical Products (pH, Conductivity, ORP, Dissolved Oxygen, etc) Oxygen Analysers, Relative Humidity Sensors and Meters, Dewpoint Measurement

workforce target of 3.2 per cent, the Water Corporation has set a new target of six per cent by September 2021.

With nearly 60 per cent of its Aboriginal employees working outside the metropolitan area, the Water Corporation will continue to employ Aboriginal people regionally, enabling them to remain on their country and connected to their communities.

Since 2007, the Water Corporation has awarded more than $7.8 million in contracts to Aboriginal and Torres Strait Islander suppliers across the state. To continue to increase this participation, it has committed to achieving a three per cent progressive procurement target over the next three years.

Western Australian Water Minister, Dave Kelly, said, “Working towards true reconciliation between Aboriginal and non-Aboriginal Western Australians is an important goal for the McGowan Government.

“We still have a long way to go to achieve a society where Aboriginal and Torres Strait Islanders are treated with the respect they deserve, and where they have the same opportunities and life outcomes enjoyed by nonIndigenous Australians.

“I want to congratulate the Water Corporation for its fifth reconciliation action plan. A robust RAP is a powerful tool to deliver practical actions which drive an organisation’s contribution to reconciliation, both internally and in the communities in which it operates.

“I look forward to working with the Water Corporation to deliver this plan, particularly by achieving greater Aboriginal and Torres Strait Islander participation in the workforce, bettering customer relations and importantly improving water infrastructure in WA’s remote communities.”

ABOUT US

Edge Underground is a precision microtunnelling contractor that operates in Australia and the USA. With a focus on innovative technology and expertise, Edge Underground designs and enhances the performance of trenchless equipment.

•

•

OUR

Microtunnelling

Pipe Jacking

SERVICES •

•

Thrust Boring

Laser Tunnel Boring

SPECIALISTS ( 0458 000 009 * stuart@edgeunderground.co 8 www.edgeunderground.co

GUIDED BORING

SCHOLARSHIP AWARDED FOR HUMAN WASTE MANAGEMENT RESEARCH

A scholarship has been awarded to a young South Australian at SA Water for a PhD looking into the environmental impact of human waste and its management.

Sarah Aucote will progress a PhD with SA Water and the University of Queensland, investigating ways to improve the operation of wastewater sludge-drying lagoons by reducing their methane emissions.

The young scientist said that promoting the activity of natural microorganisms that consume methane may reduce emissions and help contribute to climate change mitigation efforts.

“Sludge-drying lagoons are commonly

UTILITY MAY 2019 WWW.UTILITYMAGAZINE.COM.AU NEWS P E Level 2, Suite 26/20 Enterprise Drive Bundoora, Vic, 3083 1300 1 L ANCO (52626) tenders@lancogroup com au lancogroup.com.au Your business

for engineering solutions

don’t

we help our customers realize their goal, if you give us an idea we can provide a efficient and effective engineering solution” Accredited consultant with Melbourne Water, Retail Water Corporations – Metropolitan and Regional Areas Corporate Profile Insurance Category Level of Cover $ Professional Indemnity $10 million Public Liability $20 million Work Cover n/a A list of applicable insurances includes: Name of Entity: Lanco Group Pty Ltd ABN: 27 160 328 478 Company Address: University Hill Business Park South Level 2, Suite 26/20 Enterprise Drive Bundoora, Vic, 3083 Company Structure: Private Company Quality ISO 9001 Environmen Health & Safety AS 4801 ISO 14001 2

partner

Since 1998. “We

purely just design;

used around the world to treat wastewater sludge and form biosolids for agricultural application such as fertiliser, but they’ve recently been shown to contribute to the carbon footprint of wastewater treatment plants,” Ms Aucote said.

“As a young researcher, it’s incredibly satisfying to work on such a fantastic project that I believe will be beneficial not only to SA Water, but to other water utilities around the world.”

Ms Aucote received the prestigious Water Research Australia (WaterRA) Nancy Millis Memorial PhD Scholarship at the industry association’s annual international Research and Innovation Gala Dinner, which provides a combined $25,000 in project funding and travel support.

The award is given in memory of the late Emeritus Professor Nancy Millis AC MBE, who was a pioneer for women

in science in Australia, and recognises students who have demonstrated exceptional qualities and a passion for research.

“The experience and insight I will gain, along with the motivation of achieving this award, will help me to develop as a researcher and make a positive contribution to the water industry,” Ms Aucote said.

“I’m extremely thankful to WaterRA for the award, and appreciative of the opportunities my supervisors have provided me throughout the project – the continual guidance and support they have offered has been integral to my development.”

Ms Aucote’s passion for research has seen her flourish at SA Water, and her recent achievement builds on the 2018 Australian Water Awards National Student Water Prize she received for her Honours project through Flinders

University, where she graduated top of her cohort.

She is supervised by SA Water Lead Scientist Environment and Wastewater, Dr Ben van den Akker, alongside Professor Zhiguo Yuan AM and Dr Shihu Hu of the Advanced Water Management Centre at the University of Queensland.

“Her desire and commitment to helping improve the water industry through research is second to none, and we’re so proud that her efforts and qualities have been recognised through this terrific accolade,” Dr van den Akker said.

“The win was a significant achievement and reflects her individual brilliance and initiative, and it will further inspire her to keep contributing to the betterment of the water industry.”

THE MONSTER IS TURNING BLUE...

The Muffin Monster™ sewage grinders are designed to protect pumps and other equipment by grinding down the toughest wastewater solids. Available in three different models each with two different configurations, they are suitable for applications such as:

• Pump Stations

• Sludge Processing

• Correctional facilities

1800 678 910 sales@qmaxpumping.com.au www.qmaxpumping.com.au NEWS UTILITY • MAY 2019 WWW.UTILITYMAGAZINE.COM.AU 17

• Airports • Septage/Grease Receival

Australia’s biggest lithium processing plant UNDER CONSTRUCTION

The Albemarle Kemerton Plant is a $1 billion investment in Western Australia, and will become the country’s largest lithium hydroxide plant, with approval to produce up to 100,000 tonnes per annum of premium battery grade lithium hydroxide.

Premier Mark McGowan joined the United States Ambassador to Australia, Arthur B. Culvahouse Jr., State and Federal Members of Parliament and Albemarle representatives on Thursday 28 March to officially turn the sod on the Albemarle Kemerton plant.

The Western Australian Government is working with Albemarle to ensure job opportunities are maximised for local workers in Collie, Bunbury, the wider South-West and the Murray-Wellington region, with 500 construction jobs and a further 500 jobs expected to be available once operational.

An Economic Development Plan for the region will identify strategies and specific training to assist the South-West workforce to take up job opportunities created by WA’s Future Battery Industry Strategy.

The State Government is capitalising on the state’s unique resources and growth in the lithium-ion battery sector with the launch of the state’s Future Battery

Industry Strategy, and the creation of the Lithium and Energy Materials Taskforce.

Western Australia is currently the number one global producer of lithium, the second largest global producer of rare earths, the third largest global producer of cobalt and the fourth largest global producer of nickel.

Mr McGowan said he was pleased to take part in the sod-turning to mark the start of construction on Australia’s biggest lithium hydroxide project.

“In February 2018, I met with representatives from Albemarle in Washington DC to discuss the possibility of launching a lithium project of this magnitude in WA. I congratulate Albemarle on making this vision become a reality.

“My government’s number one priority is creating local jobs for local workers, so we have been working with Albemarle to make sure there are opportunities for local South-West workers from Collie, Bunbury and MurrayWellington.

“With up to 1000 local jobs being created, this project will be a huge economic boost for the South-West region and will show the capability Western Australia has in the lithium-ion battery sector.”

18 UTILITY • MAY 2019 WWW.UTILITYMAGAZINE.COM.AU NEWS

Piping Specialty Supply Service Pty Ltd PIPING SPECIALTY SUPPLY SERVICE Your "Go To" Supplier for all things Pipeline Pigs Unllmhed 'SAWYERMANUFACTURING COMPANY ,t\t\lRAGE PORTABLE PERFORMANCE More Information - please contact the PSSS team Michael Lee - QLD/NT Business Development Manager Ph: 1300 794 096 Mobile: 0418 695 779 Email: michael@psssa.com.au Martin Edge - WA/SA Regional Business Development Manager Ph: 1300 794 096 Mobile: 0418 997 664 Email: martin@psssa.com.au Andy Adina Business Development Manager NSW/ACT Ph: 1300 794 096 Mobile: 0418 546 597 Email: andy@psssa.com.au John Wilton Managing Director Ph: 1300 794 096 Mobile: 0400 794 097 Email:john@psssa.com.au 2019 CATALOGUE ENQUIRE NOW

IMPROVING SOLAR AND WIND FORECASTING

The Australian Renewable Energy Agency (ARENA), together with the Australian Energy Market Operator (AEMO) has provided $9.41 million in funding to eleven projects which trial short-term forecasting at largescale wind and solar farms in Australia.

The trial comprises at least 45 per cent of the National Electricity Market’s (NEM’s) registered wind and solar capacity, which collectively provides a total of 3.5GW of renewable electricity generation.

ARENA’s funding will help to explore the potential for wind and solar farms to provide their own, more accurate, forecasts of their output into AEMO’s central dispatch system.

The projects will enable further capability development, and provide valuable information to the market on delivering forecasts on a five-minute basis. Forecasting technology and factors that affect the accuracy of forecasts in different weather, operational conditions and geographies will also be investigated.

AEMO is currently responsible for forecasting how much electricity will be generated by wind and solar farms, the output of which varies depending on the weather and time of day. If these supply forecasts are wrong or generators cannot meet their target, it can result in power system instability and higher operating costs.

Wind and solar farms are penalised for not meeting a required output level or can be required to curtail their generation to match an overly conservative forecast.

Under the market changes that AEMO has facilitated as part of this initiative, all wind and solar farms registered in the NEM will be able to submit their own five-minute ahead forecasts to AEMO, for use in central dispatch in order to improve the accuracy of market outcomes.

The ARENA-funded trial will be exploring the benefits that this new capability brings to the system.

The portfolio of eleven projects will involve a range of weather forecasting technologies including on-site cloud cameras that can predict the timing and impact of passing

clouds on a solar farm, wind speed radars, Japanese weather satellites, infrared, crunching of Bureau of Meteorology data and machine learning algorithms.

ARENA CEO, Darren Miller, said these trials will provide test cases for wind and solar to do their own five-minute forecasts just as traditional power plants do.

“Working with AEMO, we’re supporting these trials to help avoid generators being unfairly penalised for inaccurate forecasts while also supporting system security by better matching demand with anticipated supply from variable renewable generators.

“Much like traditional energy generators, we’re aiming to show that renewable energy is now capable of providing accurate measurement of energy output,” Mr Miller said.

“With almost half of all solar and wind power generation taking part in projects in this initiative, this will lead to better deals for wind and solar farms, lower costs and more accurate data for AEMO.

“Some solar and wind farms will be sites for several different technologies and some technologies will be tested across multiple sites so we will begin to understand the strengths of different approaches in different locations.

“Improving forecasting of wind and solar generation will help better integrate variable renewable energy into the grid, reduce grid instability and reduce costs. It is a win-win for everyone.”

“We are extremely pleased to see the collaboration between market participants, forecasting service providers and ARENA to deliver highly innovative solutions to the renewable energy sector,” said AEMO’s Managing Director and Chief Executive Officer, Audrey Zibelman.

“Weather is the fuel for an ever-increasing proportion of the electricity generated across Australia, so it is vitally important that we foster innovation and rapid development of world leading technologies and services. As the market operator, we require the best possible information in realtime to manage the secure and reliable delivery of energy to Australian consumers, 24/7,” Ms Zibelman said.

20 UTILITY • MAY 2019 WWW.UTILITYMAGAZINE.COM.AU NEWS

VEGAPULS WL S 61

▪ Measuring range up to 8 m

▪ Can be used outdoors without restriction

▪ Flood-proof IP 68 housing

▪ Operation via Bluetooth with Smartphone, tablet or PC

Reliable level measurement in water treatment facilities, pump stations and rain overflow basins. Open channel flow measurement and water level monitoring. Further information: www.vega.com/wls61

Phone 1800 817 135

Low-cost level measurement. Radar sensor for water management.

DIGITAL UTILITIES 2.0:

INSPIRING UTILITY PROFESSIONALS TO CREATE A CULTURE OF INNOVATION

An effective digital strategy can revolutionise all areas of the utility sector, and embracing new technologies and business models is vital for optimising asset management, improving network operations and keeping up with changing customer demands. Representatives from Australia’s water and energy utilities recently gathered at Digital Utilities, a two-day event that provides delegates with the tools to use digital technologies to accelerate and transform their organisations.

Digital Utilities 2019 was held from 21–22 March at the Pullman Hotel in Albert Park, Melbourne, and provided a platform for utility leaders to share and discuss the challenges of digital transformation, and learn from those already seeing the benefits.

Bentley Systems — a global software development company with a portfolio of solutions that accelerate project delivery and improve asset performance — was the Event Partner for a second year running. AVEVA, which provides leading software solutions across the asset and operations lifecycles, was the Major Sponsor, with Paul Banfield, Segment Director – Water & Wastewater at AVEVA, delivering an informative presentation on the transformation of operational and business processes to enable better collaboration between people and systems.

They were joined by three other sponsors: Nearmap, which offers the most current high-resolution aerial images of areas all over Australia, so you can remotely inspect your worksite from anywhere; Peter Norman Personnel, an established professional recruitment company with long-standing relationships in manufacturing and utility industries; and Localz, which assists companies with last mile delivery services and field technician appointments.

The expert speaker lineup was spearheaded by two excellent keynotes - Nigel Watson, Group Information Services Director at the UK’s Northumbrian Water, and Mark Paterson, General Manager Consumer Energy at Horizon Power.

As international keynote, Mr Watson was able to share his tried and tested ideas around new business models, innovating and developing new products, and thinking differently by putting customers at the heart of solutions in his presentation Becoming the world’s most digital water company — at the same time highlighting what Australia and the UK can learn from each other.

“The advent of cloud computing is a major catalyst, enabling capabilities that were previously uneconomical to utilities,” Mr Watson said.

“Northumbrian Water Group has a vision to become the most digital water company in the world. Of course, this is not an objective that stands on its own. It is supportive of its key goals which are to deliver an unrivalled customer experience, continue to offer great value services and ensure that it can mitigate the impacts of climate change.”

Mark Paterson kicked off day two of the conference with his domestic keynote presentation Utility self-disruption for a low carbon future.

According to Mr Paterson, it is plausible that up to 50 per cent of Australia's electricity volume in 2050 will be generated by millions of Distributed Energy Resources (DER), creating two-way flows of power that the grid was not designed to accommodate.

“Our traditional 'poles and wires' networks will have evolved into digitised, many-to-many, transactive platforms. Enabling this transformation, however, is proving to be a monumental process of strategic change impacting all parts of traditional utility businesses.”

22 UTILITY • MAY 2019 WWW.UTILITYMAGAZINE.COM.AU NEWS

These keynote presentations were supported by five interesting and informative presentations:

• Kate Fuelling, Digital Excellence Consultant: Digital transformation — we are doing it wrong

• Geoff Purcell, Chief Technology Officer at Melbourne Water: From utility to digital business innovator — learnings from our digital transformation journey

• Maree Mamo, Partner, Management Consulting at KPMG: Lessons learned from large-scale transformation

• Amanda Finnis, Chief Information Officer at Coliban Water: Water utilities and emerging technologies: where’s the killer app?

• Wayne Pales, General Manager Technology Strategy at the Australian Energy Market Operator (AEMO): Demand Response — crossing the chasm from pilots to operations

Day one also included a panel discussion on Achieving cyber security resilience, where Mr Watson joined Ian McKenzie, General Manager IT Operations and Service Management at Jemena, and Michael McKinnon, Strategic Information Security Advisor and Principal Consultant at PS&C Security. They offered delegates advice on how to keep their data and digital assets secure, prepare for and respond to cyber attacks, and create a culture where identifying security risks becomes the responsibility of every employee.

PANEL DISCUSSIONS OFFER A VARIETY OF PERSPECTIVES

The second day of Digital Utilities 2019 featured four panel sessions, split into morning and afternoon streams.

The stream, The connected customer — staying relevant in a changing world, featured Toby Evans, Senior Manager Digital Transformation at SA Water; Michelle Grigg, Marketing Manager at Powershop and Rita McPhail, Manager Customer Engagement and Programs at SA Power Networks.

These three panellists discussed how utilities can provide their customers with a rich digital experience that is both mobile and social, and empowers them to take control of their water and energy use. This is not an area where the sector has historically excelled and change is needed, with technology playing a major role in overhauling the way the industry interacts with its customers.

During the other morning stream, delegates heard from Graham Rix, Chief Information Officer at SA Water; Caroline Hussey, Team Leader Business Enablement, Service Delivery at Melbourne Water; and Cate Hilliard, Manager, IT Capital Portfolio at SA Power Networks for a panel session titled A new core — unleashing the digital potential in utility operations

Fuelled by advances in artificial intelligence, data analytics, robotics, the Internet of Things (IoT) and cloud computing, digital technologies are transforming the way utilities operate — how they create value, serve customers, manage costs, optimise processes and capture new market opportunities. Our panellists delved into how to use digital technologies to

improve operational efficiency and workforce mobility.

The afternoon streams had a specific sector focus, with one exploring how high levels of variable renewable energy and DER have increased the complexity of electricity network management, while the other discussion centred on how Australia’s rapidly growing population and climate change are increasing the pressure on water resources.

As part of the Innovation in electricity networks — building the grid of the future panel, Fiona Bishop, Executive Manager Change and Innovation at Western Power; Dr. Adam Bumpus, Senior Researcher at the Energy Transition Hub; and Eddie Thanavelil, Demand Side Innovation Engineer, Customer Connections at Evoenergy talked about the process of grid modernisation, and how energy companies can navigate this complex transformation while keeping the lights on and prices down.

The panel, The smart water utility — improving water management featured Terri Benson, Managing Director at South East Water; Colin Chapman, Innovation, Research and Development Manager at Queensland Urban Utilities; and Pablo Ledezma from the CRC for Water Sensitive Cities looking at how water utilities are adopting and leveraging smart water and wastewater technologies to deliver greater value to customers and improve asset performance and longevity.

The Super Panel, featuring seven key speakers from across the two days, wrapped up the conference and offered a ‘big picture’ view of all the topics covered.

DEVELOPING INDUSTRY CONNECTIONS

In addition to knowledge-sharing, the aim of Digital Utilities 2019 was to enable delegates to network and meet other members of the utility community.

Multiple speed networking sessions provided delegates with introductions to colleagues and other industry professionals. These formal sessions were in addition to the multiple opportunities to connect with other attendees during the networking lunches and breaks.

Exhibitors from digital and technology related companies were also there to showcase the latest innovations in the sector, helping delegates gain a better understanding of how to integrate digital solutions within their organisation. The exhibition area was triple the size of the inaugural 2018 event, offering delegates access to a variety of new and emerging technologies.

For many of the organisations attending, one of the main highlights of the event was finding out the winners of 2019 Digital Utility Awards at the Digital Utilities gala dinner and awards ceremony — full coverage of this evening of fun and celebration is over the page.

The third annual Digital Utilities event will be held again in the first half of 2020 – keep reading Utility in print and online so you can stay up to date with all the details as they are announced.

UTILITY • MAY 2019 WWW.UTILITYMAGAZINE.COM.AU 23

WINNERS OF THE 2019 DIGITAL UTILITY AWARDS ANNOUNCED

The winners of the 2019 Digital Utility Awards were revealed on Thursday 21 March at a gala dinner and awards ceremony that was held as part of Digital Utilities 2019. Six awards were handed out in total, celebrating the utility industry’s greatest achievements in the digitisation of utility networks, processes and practices across Australia.

The calibre of entries for this year’s awards was extremely high and choosing the winners proved to be a difficult decision for the panel of judges which included Adam Lovell, Executive Director, Water Services Association of Australia; Andrew Dillon, CEO, Energy Networks Australia; and Cassandra Hogan, National Sector Leader – Power & Utilities, KPMG. The three judges have a wealth of experience across water and power utilities.

Sponsored by Bentley Systems, a global software development company with a portfolio of solutions that accelerate project delivery and improve asset performance, the Digital Utility Awards gala dinner was attended by senior

leaders and experts from utilities around Australia. Both the awards and the Digital Utilities conference aim to gather some of the best ideas when it comes to the digital transformation of utilities, so that all of the industry can benefit from some of the impressive changes that are being made as we make this journey towards being truly digital utilities.

The winning entries were deemed the best in utility digitisation for 2019, and were among high-quality finalists in each category. Utility would like to congratulate all the finalists and winners of the awards and looks forward to working with the industry again for next year’s event.

24 UTILITY • MAY 2019 WWW.UTILITYMAGAZINE.COM.AU NEWS

BEST CUSTOMER INNOVATION

In recognition of the best digital innovation focused on improving customer outcomes.

FINALISTS:

Endeavour Energy – for its interactive mapping portal providing information on network limitations

Flux Federation – for its retail platform that was purpose built for energy companies

Jemena – for its demand response program ‘Power Changers’

Sydney Water – for the development and implementation of its Customer Hub

TasNetworks – for its Voice of the Customer Program

TracWater – for its Portable Robotic Water Quality Analyser

Utilibill – for its cloud-based retail platform disrupting the utility billing space

WINNER: JEMENA

YOUNG DIGITAL LEADER OF THE YEAR

Awarded to the young person (under 35) demonstrating outstanding performance and passion for achieving digital transformation within their utility.

FINALISTS:

Adam Severino – Sydney Water

Jack Cunnington – City West Water

Lucille Burkitt – Queensland Urban Utilities

Luke Dix – SA Water

WINNER: ADAM SEVERINO

BEST USE OF NEW TECHNOLOGY

In recognition of the best new technology in place across a utility network.

FINALISTS:

GHD and Unitywater – for their sewer overflow prediction tool utilising machine learning

Icon Water – for the modernising of its GIS system

SA Power Networks – for its MyWorkday automated timesheet solution

Synergy – for its use of Robotic Processing Automation and IQ Bot introduction

Unitywater – for its Mobile Field Office solution

Western Power – for its Field Mobility Services program

WINNER: SA POWER NETWORKS

DIGITAL UTILITY OF THE YEAR – ENERGY

Awarded to the energy utility showcasing the best use and implementation of digital technologies, tools and processes across their organisation.

FINALISTS:

Evoenergy

Jemena

SA Power Networks

Western Power

WINNER: SA POWER NETWORKS

UTILITY INNOVATOR OF THE YEAR

Awarded to the individual making the biggest contribution to the digital transformation of their utility.

FINALISTS:

Andrew Forster-Knight – South East Water

James Ireland – TRILITY

Karen Pollock – Queensland Urban Utilities

Margarita Camus – Queensland Urban Utilities

Toby Evans – SA Water

WINNER: ANDREW FORSTER-KNIGHT

DIGITAL UTILITY OF THE YEAR – WATER

Awarded to the water utility showcasing the best use and implementation of digital technologies, tools and processes across their organisation.

FINALISTS:

Queensland Urban Utilities

SA Water

South East Water

Sydney Water

WINNER: SYDNEY WATER

NEWS UTILITY • MAY 2019 WWW.UTILITYMAGAZINE.COM.AU 25

Quantum Filtration Medium

“

- Mr. Clive R. Hawkes, Managing Director

The combined effects of the additional clarification, polymer optimisation, new filter nozzles and addition of DMI-65® filter media, will see the plant achieve high water quality all year round and will allow for increased throughput capability, in times of high load.

“

The upgrade has provided KLPP low cost solutions, utilising the existing plant and equipment, to increase the quality and quantity of water to the power plant, whilst reducing maintenance and on-going operating costs. “ “

Kuala Langit Power Plant

Mr. Kumar Shanmugan, Power Station Manager

“Advanced Filtration Media”

DMI-65® for Turbidity and Total Suspended Solids Removal

REMOVAL OF TOTAL SUSPENDED SOLIDS AND TURBIDITY: The DMI-65® particle size distribution is engineered to provide a perfect filtration coefficient resulting in excellent mechanical filtration lowering total suspended solids (TSS) to less than 1mg/L and turbidity levels less than 1 NTU.

IRON AND MANGANESE BUILDUP: Build up of iron and manganese results in very high maintenance overheads, loss of production and potentially system failure. DMI-65® efficiently removes dissolved iron to the almost undetectable levels as low as 0.005mg/L and manganese to 0.001mg/L as well as particulate, effectively removing this risk.

REDUCED COSTS: The total cost of the iron and manganese removal water filtration system is significantly less than alternative solutions, the effectiveness, but relative simplicity, of DMI65® based systems reduces the upfront capital expenditure on plant complexity as well as the ongoing operational expenditure in chemicals, power and backwash waste water recovery.

HIGH FLOW RATES: The infused technology of DMI-65® promotes the highest oxidation rate of any catalytic filtration media. This permits a significantly higher water flow rate to achieve the same level of iron and manganese removal. DMI-65 can operate at linear filtration velocities up to twice that of conventional media with a corresponding reduction in capital equipment costs.

HIGH LOAD CAPACITY: DMI-65® also has higher iron and manganese load capacity which can extend the duration of filter runs and the time between backwashing, thereby reducing downtime, operating expense and wastage.

REGENERATION NOT REQUIRED: The media operates with a continuous injection of sodium hypochlorite at low residual levels (0.1 to 0.3mg/L) which eliminates the need for Potassium Permanganate.

WIDE OPERATING ENVIRONMENT: Stable and satisfactory performance at pH 5.8 to 8.6 and a maximum operating temperature of 113° F (45°C) reduces the need for investment to alter the operating environment.

LONG LIFE:

DMI-65® is not consumed in the process giving it an expected operational life of up to 10 years, providing considerable advantages over other processes or media. The media does not display a decaying capacity to do its catalytic work. Over the 5 to 10 year period, through many backwashing operations of the bed to remove retained solids, an attrition loss of the media occurs by contact between particles and mechanical abrasion.

www.dmi65.com

info@dmi65.com

+61 1300 303 281

WATER MANAGEMENT OF THE HIGHEST ORDER

UTILITY • MAY 2019 WWW.UTILITYMAGAZINE.COM.AU 28 WATER MANAGEMENT

In January 2019, Professor Zhiguo Yuan, Director of The University of Queensland’s Advanced Water Management Centre, was appointed as a Member of the Order of Australia. This award recognises his significant service to science through urban water management, and to higher education. Utility Editor, Charlotte Pordage, caught up with him to learn more about one of Australia’s most esteemed engineers.

Professor Yuan said that he felt extremely honoured to receive the award, and also very humbled.

“There are so many others that probably did more than me, without receiving an honour like this. I feel I’m doing my part for water industry innovation, but this is not something that can be done by an individual or even a small team. For the past 20 years, I’ve been working with a large number of people who I regard as the innovators of the water industry,” Professor Yuan said.

No stranger to accolades, Professor Yuan’s other notable awards and appointments include:

• Appointed Distinguished Fellow, International Water Association, 2018

• Recipient, Laureate Fellowship, Australian Research Council, 2017

• Recipient, National Research Innovation Award, Australian Water Association, 2017

• Appointed Fellow, Australian Academy of Technological Sciences and Engineering, 2015

• Recipient, Clunies Ross Award, 2015

• Recipient, Global Project Innovation Award, International Water Association, 2014

• Recipient, Graduate School Supervision Award, University of Queensland, 2010

• Recipient, Excellence Award in Research, Development and Innovation, Engineers Australia, 2008 Professor Yuan began his studies in aeronautical engineering, receiving a PhD in 1992 from Beijing University of Aeronautics and Astronautics in China.

He shifted his research direction to wastewater management in 1994 after taking up a postdoctoral research fellow position at Ghent University in Belgium and not feeling fulfilled by his work in the aeronautical sector.

“I wanted to do something that allowed me to contribute to society. I decided to change to environmental engineering, since environmental issues were gaining a lot of attention at the time and I thought it was something I may be able to apply my skills to,” Professor Yuan said.

On 22 March 1998, Professor Yuan arrived in Australia and started his career with the Advanced Water Management

Centre (AWMC) at The University of Queensland. He was promoted to Deputy Director of the AWMC in 2001 and then Director in 2015.

One of the things Professor Yuan enjoys most about his current role is working with industry to solve real-world problems.

“When I launched my career, I wanted to work on things that were relevant and that could address real issues. Working closely with the utility industry aligns very well with my initial objective. Research should not just be contained to the laboratory.”

Professor Yuan is also passionate about supervising and mentoring researchers in the early stages of their careers.

“Twenty years ago, I was a young researcher, but now I’m becoming one of the most senior people in the centre, both in terms of age and also in terms of experience. Since then, we have attracted a lot of talent to the centre, which is one of the top research centres in the world in urban water management, and all our staff and students contribute immensely to its success,” Professor Yuan said.

By supervising and mentoring the next generation of research leaders, I feel I’m building capacity not only for the centre, but also for the nation. Although I’m very busy, I never tire of the meetings with my PhD students and younger researchers. I meet with them often, discussing research projects and how they should develop their ideas.”

MAKING BETTER USE OF WATER RESOURCES

Even when he is juggling close to ten projects at a time, Professor Yuan does not just like to oversee something, he prefers to be deeply involved.

Right now, his research is focused on three main areas: sewer corrosion and odour management, resource recovery and reuse, and integrated water management.

Professor Yuan was one of the founding members of the $117 million Cooperative Research Centre for Water Sensitive Cities and was leader of the Future Technologies Program.

He explained that the main challenges and opportunities currently facing the water industry are not very different from many other sectors.

29 UTILITY • MAY 2019 WWW.UTILITYMAGAZINE.COM.AU WATER MANAGEMENT

Water management of the highest order

“The three big ones are population growth, urbanisation and climate change. These are the challenges driving many industries, but water in particular is very sensitive to those challenges.

“We can’t really continue to build more dams, to source water from outside. We can’t just expand our cities and large networks, our centralised water supply and wastewater treatment systems. We need to look at integrating different water sources that we don’t normally look at.

“That includes recycled wastewater, because wastewater is 99.9 per cent of water, and stormwater. We receive a lot of water from the sky, but the problem is we’re not retaining it. It hits impermeable ground, forming runoff and then just flows into the rivers. We lose that water, and we also contaminate our rivers because the runoff contains a lot of pollutants."

Professor Yuan sees decentralised business models as a key component of integrated water management.

“Currently we rely mainly on central services. When you have more people living in denser cities, you’ve got more high-rises, and that means we need to provide more water and wastewater services.

“Decentralised solutions are usually more expensive, but let’s look at it from a different perspective. Imagine a city where the population increases by 50 per cent, what do you do with your basic infrastructure? You have to build new networks, which is not a trivial task in an established area.

“By providing decentralised services, you don’t have to expand your central facilities tomorrow, next year or in 20 years’ time. You do spend more money per cubic metre of water in comparison to centralised services, but you delay that major capital investment, meaning that your decentralised solution may not be that expensive anymore. With decentralised solutions, we can also have fit-for-purpose water production.

“Decentralised systems give us a lot of flexibility, and you can actually produce water with the quality that you need. If you need to water your garden or your green space, then you just remove the pathogens in greywater. But you definitely don’t need to make water that is suitable for drinking for gardens.

“In Brisbane, we have water recycling plants, where wastewater is purified to produce high-quality water. The issue here is that central wastewater services are often situated at the low point in a city, because you want to have sewage flowing to that point with minimum energy input. To produce recycled water there, the treated wastewater has to be pumped for tens of kilometres to distribute it back to households and businesses. If you have decentralised solutions you don’t need to transport that water — it’s available where it’s needed.”

THE IMPORTANCE OF INDUSTRY PARTNERSHIPS

One of the core aspects of integrated water management is that it requires collaboration between all of the organisations that influence the water cycle. While collaborative approaches tend to deliver better outcomes for communities, there are challenges involved when disparate organisations have to work together.

Professor Yuan recently led an industry linkage project with a number of partners, including Seqwater, Queensland Urban Utilities, DC Water in the US, Public Utilities Board in Singapore and Water Research Australia, that investigated the integrated management of the sludge generated in drinking water production.

He cited this project as an example of how important it is to bring different organisations together to address problems that can impact multiple stages of the water cycle.

“A key step in water treatment is the addition of a coagulant to remove natural organic matter and suspended solids. Typically, you would add aluminium sulphate and the aluminum would drop out with the solids and organic matter, forming drinking water sludge,” Professor Yuan said.

“The sulphate is soluble and actually stays in the drinking water. In the human body, it’s not going to induce any health issues, because we can tolerate quite high levels of sulphate. It’s a big problem for the sewer network however, because we have corrosion and odour issues through the formation of hydrogen sulphide.

“There is a strong need to change the coagulant in drinking water treatment. It’s a billion dollar problem and 70 per cent of drinking water plants across the world use aluminium sulphate. Drinking water providers may not see the addition of aluminium sulphate as an issue, because it’s cheaper than other coagulants and can produce high-quality water. The effect on wastewater is no good though.

“The addition of ferric chloride to the sewer network for sulphide control is a well established strategy, and if you use ferric salts for drinking water production, the ferric will separate from the water into your sludge.”

With the findings from this project, Professor Yuan said that there is a good opportunity for water and wastewater service providers to work together, despite their different roles in the water industry.

“I’d like to highlight the importance for researchers and industry to work together. Researchers want to solve real problems, not fake problems,” Professor Yuan said.

“We have the knowledge, science and technology to support industry and we can use these strengths to provide fundamental solutions.”

UTILITY • MAY 2019 WWW.UTILITYMAGAZINE.COM.AU 30 WATER MANAGEMENT

Filtec is pleased to announce the acquisition of Practical Filtration Solutions (PFS) – a Melbourne-based water treatment design, installation, and servicing specialist of a variety of water treatment systems.

Filtec, a New Zealand based design, construction, service and water treatment optimisation company, has been operating in Victoria for four years and formed a partnership with PFS in 2018 via its subsidiary Filtec International. The two companies have delivered a number of key projects in the industrial and municipal water treatment sectors, leveraging Filtec’s design and fabrication capability, and PFS’ local presence and experience.

Founded in 2002, PFS has significant experience in water filtration, membranes, desalination and process separation. Combining the best technology sourced from around the world with the best local service and support, Filtec and PFS both have established reputations for turning leading global technologies into bespoke solutions.

Filtec and PFS combined will have over 80 people in New Zealand and Australia, with a turnover of NZ$40 million in 2019. PFS ceased trading from 1 April 2019 and will operate as Filtec International.

With a growing recognition of water purity and public safety, and the obligation to care for what we return into our environment, industrial and municipal customers in both New Zealand and Australia are relying more on water treatment, re-use and conservation specialists like Filtec.