Simply working & sustainable

Since 1985 we have installed more than 1,850 km of track 1.7 billion load tonnes | equivalent of 50 years use

Application: Ballast, Slab Track, Steel Construction and Direct Fastening

Can carry Axle loads of up to 65 tons

Use on High Speed Rail up to 300 km/h

Maintains long term track geometry

Contact with ballast similar to timber sleepers

Workable properties like timber sleepers

26|

32|

34

RAIB’s annual report shows no room for complacency 2022 saw 16 railway accidents on the main line network. RAIB’s report addresses its most significant areas of concern.

New fleet introduction and fleet cascades

With 8,000 new vehicles ordered in the 2010s, their introduction and the cascade of older vehicles was far from smooth.

Train depots for today and tomorrow

Rail Partners brought operators, suppliers, and other stakeholders together to discuss depot safety and productivity.

Designing a safe and efficient depot

The Train Depots for Today and Tomorrow event examined the concept for HS2’s forthcoming Washwood Heath depot.

34|

How can robots make depots more effective?

Our final report from the Rail Partners depot event gave us a glimpse of the future.

66

36|

44|

48|

54|

60|

And then there was AI Malcolm Dobell reports from the Rolling Stock Maintenance and Depot Innovation conference held in June.

The connected asset –when a cab radio is not (just) a radio

The GSM-R cab mobile asset could be used to reduce costs, increase operational efficiency, and improve customer benefits. Customer information developments

Accurate information is essential for customers, as Paul Darlington discussed with Network Rail and the Rail Delivery Group.

HS2’s future stations

We take a look at the progress made at HS2’s new stations in London and the West Midlands.

Rail Live 2023

The UK’s largest outdoor rail show returned in June to Porterbrook’s Long Marston Rail Innovation Centre.

64|

66|

Energy harvesting & ‘fit and forget’ wireless sensors

Intelligent infrastructure and remote condition monitoring systems are essential for the maintenance and management of today’s railway assets.

HS2: an eco-plant test bed

HS2 is collaborating with the industry and its supply chain to accelerate innovation in low carbon plant and equipment.

68| Best challenge yet

76|

The quality of entries at this year’s Railway Challenge was the highest the judges have ever seen.

Unlocking innovation at the robotarium

RIA’s latest event brought a wide range of delegates together at Edinburgh’s Heriot-Watt University.

2018 saw the last Long Term Passenger Rolling Stock Strategy (LTPRSS). Yet with the UK’s rolling stock fleet comprising of 14,000 vehicles and costing £3 billion per annum, there is clearly a need for the overview that LTPRSS used to provide.

In 2021, the Government’s Transport Decarbonisation Plan committed to an ambitious electrification programme and the deployment of battery and hydrogen trains. Yet there is no visibility of any such plans. That year also saw the Williams Shapps report which bemoaned the absence of strategic planning which the McNulty Review highlighted in 2011. It noted that work had started on a 30-year Whole Industry Strategy Plan (WISP) to be produced in 2022.

Infrastructure schemes are part of the Rail Network Enhancement Pipeline which was published in 2018 and has not been updated since 2019 despite the promise of annual updates.

The Great British Railways Transition Team (GBRTT) is expected to publish a WISP, of which rolling stock is a subset, by the end of the year. Yet, with no sign of a rolling electrification programme, and no orders for conventional rolling stock for almost four years, decisions are needed now. Doing nothing is an expensive option. Against this background, the Railway Industry Association (RIA) has done the industry a great service by publishing its report ‘The UK Rolling Stock Industry – making 2023 the year of opportunity not crisis’. It shows how the ‘boom and bust’ procurement that characterises

UK rolling stock orders has resulted in factory closures and downsized the UK’s train upgrade capability. The current lack of orders will increase costs in the longrun as the lack of continuous production reduces productivity and reduces the skilled workforce. In addition, increasingly elderly trains will become significantly more expensive to operate and maintain.

In 2011, the UK had one new build factory. Following a glut of 7,300 vehicles ordered between 2012 and 2017, there are now five. These factories, and thousands of jobs, are now at risk. One has already run out of work and two will do so next year. The RIA report shows that UK rolling stock is a high productivity industry with the average employee generating gross value added of almost £105,000. This compares to an average of £65,000 in the manufacturing industry.

FIG 1case for new trains can be disputed, ‘no brainer’ would be a better description.

Introducing the 8,000 new vehicles ordered in the 2010s presented many notso-obvious challenges both for their new operators and those receiving cascaded older vehicles. In a comprehensive feature, Malcolm Dobell explains how train fleet introduction is a major business change programme for which detailed planning and building effective collaborative relationships is essential.

By 2030, around 2,600 vehicles will be over 35 years old. New trains are needed, not only to reduce costs, but to improve passenger services and meet decarbonisation commitments. ETCS also has to be considered given the cost of retrofitting old trains. Another issue is the lack of electrification plans which makes it difficult to specify the type of trains, though such uncertainties can be partly addressed by procuring battery EMUs and bi-mode trains.

RIA’s report also points out that, unlike infrastructure investment, new trains don’t need a large upfront public investment as the use of private finance to procure rolling stock is common practice. It explains why ordering new trains is a ‘no regrets’ decision. As it is difficult to see how RIA’s

A recent seminar considered how these large new fleets presented many challenges for depot operators. This included a GBRTT presentation on the emerging strategy for train maintenance, depots, and stabling to address the rapidly developing mix of all traction types. It focuses on location, aligned objectives for all concerned, best use of data, and best possible maintenance delivery.

On a much smaller scale, producing, modifying, maintaining, and operating miniature locomotives for the Railway Challenge has provided hundreds of young engineers with an excellent development opportunity. As we report, this event has been run by volunteers from the IMechE’s Railway Division since 2012 and was the best challenge yet.

Continuing the depot theme, we describe how HS2 is designing its Washwood Heath depot to be as safe and efficient as possible and how Artificial Intelligence (AI) and robots can make depots more effective. The National Robotarium was the location of a wide-

FIGURE 1 - Class 385 unit being built at Hitachi’s Newton Aycliffe factory which opened in 2015.ranging RIA Unlocking Innovation Event which showed how the widespread use of robots may not be many years away.

Fitting 12,000 upgraded GSM-R cab radios also presented significant challenges for which improved quality of communications is just one benefit. Others include Connected Driver Advisory Systems, and train-borne condition monitoring. Perhaps most importantly, they are future proofed as they can be upgraded to use the Future Railway Mobile Communication System.

The cross-industry Smarter Information, Smarter Journeys programme aims to communicate better and simpler customer information. As Paul Darlington reports, effective collaboration has delivered a range of initiatives. He also considers the latest in customer information displays at stations.

Our article on HS2’s stations includes the sad saga of HS2’s London Euston terminus where high costs have forced a pause and a third design rethink. The resultant abortive design work was cost hundreds of millions of pounds.

The Controlling the Elizabeth line feature included in the printed edition of Rail Engineer 202 (May/June 2023) unfortunately contained an incorrect statement that the Rigid Overhead Conductor (ROC) system used instead of a catenary was installed because it was perceived to require less maintenance and that in practice this was not the case.

In the public discussion about Euston, hardly anything is said about how terminating at Old Oak Common or reducing Euston’s platforms reduces HS2’s capacity. Tens of billions are being spent on the HS2 phase one line which will provide benefits of an equivalent value and free up a large amount of capacity on the existing railway.

As this is intended to be the trunk of Britain’s high-speed rail network, it is designed to carry 18 trains per hour. The latest leak suggest that Euston may only have seven platforms. If this is true, it would significantly reduce HS2 phase one’s capacity and so throw away benefits worth billions. This would also irrevocably reduce the capacity of any future high-speed network.

Safety on our railways is a good news story, though as the Railway Accident Investigation Branch’s (RAIB) annual report shows there is no room for complacency. Our feature highlights the key issues in this report which we hope will encourage readers to study the incident reports and summaries of learning published by RAIB that relate to their work.

The reality is that the ROC system was chosen primarily for the management of limited clearances and has given such good performance that it has been possible to double the period between maintenance inspections as a result of operational experience.

Although the online version of the article and the online PDF of the magazine contains the correct statement, Rail Engineer would like to assure readers of the printed edition of the magazine that the ROC system offers significant clearance and maintenance benefits.

Rail Engineer apologies for this error.

Editor

David Shirres

david.shirres@railengineer.co.uk

Production Editor

Matt Atkins matt@rail-media.com

Production and design

Lauren Palin

lauren@rail-media.com

Adam O’Connor adam@rail-media.com

Engineering writers

bob.hazell@railengineer.co.uk bob.wright@railengineer.co.uk clive.kessell@railengineer.co.uk david.fenner@railengineer.co.uk graeme.bickerdike@railengineer.co.uk malcolm.dobell@railengineer.co.uk mark.phillips@railengineer.co.uk paul.darlington@railengineer.co.uk peter.stanton@railengineer.co.uk

Advertising

Asif Ahmed asif@rail-media.com Craig Smith craig@rail-media.com

Rail Engineer

Rail Media House, Samson Road, Coalville Leicestershire, LE67 3FP, UK. Switchboard: 01530 816 444 Website: www.railengineer.co.uk

Rail Engineer Videos http://rail.media/REYouTube

Editorial copy to Email: news@rail-media.com

Free controlled circulation

Email: subscribe@rail-media.com

The small print

Rail Engineer is published by RailStaff Publications Limited and printed by PCP Ltd.

© All rights reserved. No part of this magazine may be reproduced in any form without the prior written permission of the copyright owners.

Part of: ® www.rail-media.com

On 27 July, a court sentenced Transport for London (TfL) and Tram Operations Ltd (TOL) to fines of respectively £10 million and £4 million for safety offences in respect of the fatal Croydon tram accident on 9 November 2016. This occurred after a tram overturned due to its overspeeding on a sharp curve. This followed a hearing in June 2022 when TfL and TOL both pleaded guilty to breaches of section 3 of the Health and Safety at Work etc Act 1974. This requires them not to expose persons not in their employment to risks to their health or safety. In June this year, the tram driver was found not guilty of failing to take reasonable care of his passengers after a trial at the Old Bailey.

The Rail Accident Investigation Board (RAIB) report published its report on the Croydon tram crash in December 2017. This concluded that the driver probably lost awareness and that the tunnels approaching the curve did not have sufficient identifying features to alert drivers

as they approached the curve. The report also found that the driver “had no record of driving at excessive speed, had no known relevant medical conditions and was regarded by TOL as reliable and compliant with the rules.”

RAIB considered that an underlying factor was that TfL and TOL “did not recognise the actual level of risk associated with overspeeding on a curve”. One reason for this was that there was a reluctance of some drivers to admit their own mistakes. A further issue was that the risk from excessive speed around curves was “neither fully understood by the safety regulator nor adequately addressed by UK tramway designers, owners and operators.”

Prior to its opening in 2000, the Croydon tramway was approved by Her Majesty’s Railway Inspectorate (HMRI) which became part of the Office of Rail Regulation (ORR) in 2006. This approval was on the basis of relevant standards including guidance published by HMRI which was based on line-of-sight driving. Other than speed signs, this document did not require mitigation at curves.

The RAIB report specifically considered the role of the ORR and found “no evidence that HMRI/ORR had fully recognised the potential for multiple fatality accidents involving trams.”

Recommendations in the RAIB report included the need for the UK tram industry to:

» Develop a body for effective UK-wide cooperation on safety, good practice, and standards.

» Systematically review operational risks.

» Install suitable measures to automatically reduce tram speeds at high risk locations.

» Consider systems to detect and automatically respond to low level of driver alertness.

In response, the Light Rail Safety and Standards Board (LRSSB) was formed in 2019. Much other work has been done to implement these recommendations. This includes the development of an overspeed protection system, as reported in issue 173 (April 2019) and the trial of wrist worn devices to monitor driver alertness.

Prosecuting the companies responsible for the Croydon tram crash cost £1 million (the costs they had to pay) and took nearly seven years.

In his sentencing remarks, the Judge explains that he considered both parties to be highly culpable as there was no effective risk assessment for overspeeding on curves. Moreover, tunnel lighting needed to assess braking points had been defective for some time, recommendations for extra signage and a near-overturning incident at this location had not been considered.

FIGURE 1 - Tunnel gaps on approach to the curve were used as braking points. In the dark, these gaps were not visible to the driver due to defective lighting CREDIT: RAIB

His remarks explain how, as well as high culpability, sentencing guidelines also require consideration of the severity of the event and the size of the organisation. Taking all factors into account he fined TfL £10 million and TOL £4 million. The judge felt that the deterrence value of this fine would benefit the travelling public in the long run.

The preface of every RAIB report states that the purpose of its investigation “is to improve railway safety by preventing future railway accidents or by mitigating their consequences.” RAIB’s report into the fatal Croydon accident took just over 12 months. Thereafter, the industry implemented its recommendations. This included the formation of LRSSB which has improved the tram sector’s understanding of risk and set recognised industry standards. In addition, new safety measures are now being implemented to prevent trams speeding around tight curves and manage driver attentiveness.

In contrast to this ‘no blame’ approach, it took seven years and cost £1 million for the judicial process to fine the companies concerned a total of £14 million. In his sentencing remarks the judge noted that “neither TfL not TOL were charged with causing

deaths.” Their failure was not to control a risk, the actual level of which was not appreciated. However, as the RAIB report showed, the lack of understanding of the potential for multi-fatality accidents was common throughout the industry, including the ORR which launched the prosecution against both TfL/ LOR and the driver.

Readers are invited to draw their own conclusions on which approach better prevents accidents.

A multi-fatality accident such as the Croydon tram crash clearly has a devasting impact on all concerned including the driver whose mistake cost the lives of seven people. In this respect, the judge in the TfL/TOL case demonstrated his understanding of the driver’s position by noting that he “had an exemplary driving record and was a careful driver who took pride in his job. He was one of the network’s best and safest drivers. The derailment that morning could have happened to any of the drivers on the network; it just happened to be him.”

Whilst making these comments the judge quoted from HSE publication HSG48 ‘Human failure and accidents’ which challenges the belief that incidents are simply the result of ‘human error’ as “organisations must recognise that they need to consider human factors as a distinct element which must be recognised, assessed and managed effectively in order to control risks.”

Whilst it is questionable whether multi-million-pound fines prevent accidents, it is good to see the judiciary recognising that human failure does not necessarily make someone a criminal. It is not that long ago when a rail worker was jailed for such a mistake.

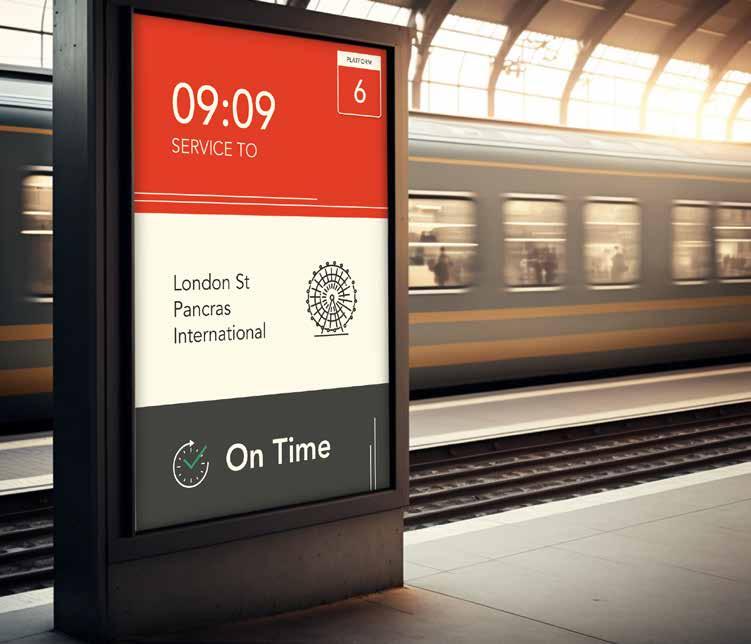

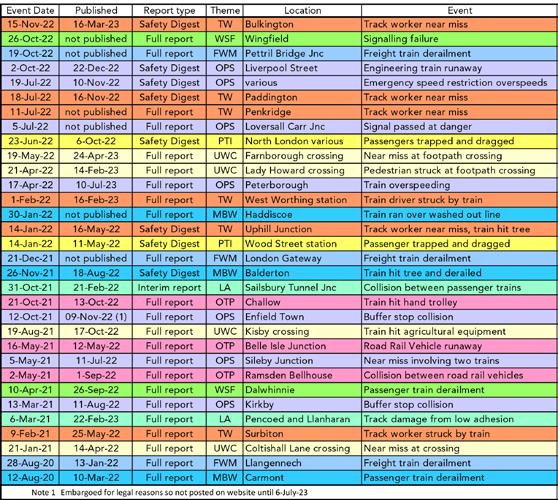

This year’s Railway Accident Investigation Branch (RAIB) annual report shows that, in 2022, there were 16 railway accidents on the main line network requiring RAIB investigations. During the year the Branch published 14 full reports and 8 safety digests as shown in table 1.

The report describes how RAIB had published nine ‘Summaries of Learning’ (SoL). These address the most significant areas for which RAIB has concerns about the control of risk due to

recurrent issues since its first investigations in 2005. Table 2 shows the relationship between these themes and those of RAIB’s annual report which form the basis of this feature which primarily concerns incidents on the GB main line railway network. However, RAIB’s remit also covers Metros, Heritage Rail, the Channel Tunnel, and Northern Ireland. In 2022 it considered five Metro accidents as shown in table 3.

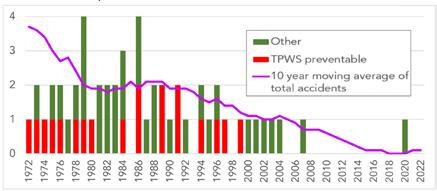

Graph 1 shows the significant reduction in fatal train accidents over the past 50 years and how the Train Protection Warning System (TPWS) has reduced such accidents. Whilst fatal train accidents are rare, other types of fatal accidents regularly occur on the national rail network, for example workforce, platform, and user worked crossing accidents. Table 4 shows a 37% reduction in such rail fatalities over the past ten years. Yet, sadly, annual suicides have increased from 216 to 261 over this period. Whilst this safety improvement is good news, RAIB’s annual report shows that much more needs to be done, especially as, in slightly different circumstances, some accidents could have been multi-fatality events.

DAVID SHIRRES Derailed tank wagons at Llangennoch CREDIT: RAIB

Table 2 shows how operations accounted for the highest number of accidents considered by RAIB in 2022. These included two buffer stop collisions and two signals passed at danger. Maintaining full concentration whilst driving trains is a demanding task. Hence RAIB recommends research into the detection and mitigation of driver’s loss of attention, and support for drivers in respect of fatigue and lifestyle management.

TPWS was implemented over 20 years ago as a stop-gap measure until the implementation of automatic train protection provided by ETCS. Although it is not a failsafe system, it has significantly reduced operational risk. Yet, with widespread ETCS deployment remaining many years away, RAIB questions whether TPWS provides sufficient risk mitigation.

An overspeeding incident at Peterborough in April 2022 showed how neither TPWS nor current signalling standards provided sufficient risk mitigation for a train routed from the Up Fast to the Up Slow line. As the train approached the junction control signal was displaying in red aspect until the train was 790 metres away travelling at 25mph. It then changed to a green aspect with its junction indicator (a string of five white lights) showing that the train was routed on to the Up Slow. The driver did not react to this indicator and then applied power which accelerated the train to pass the signal at 64mph, after which it passed over a set of points restricted to 30mph at 76mph.

Table 2 - Accident themes

Table 3 - RAIB metro / light rail investigations started, published or ongoing in 2022

Graph 1 - Number of fatal train accidents

Table 2 - Accident themes

Table 3 - RAIB metro / light rail investigations started, published or ongoing in 2022

Graph 1 - Number of fatal train accidents

FIGURE 1 - Driver did not react to this signal’s junction indicator when its red aspect changed to green CREDIT: RAIB

Thirteen months later, there was another overspeeding incident at this signal. Since then, the approach control at this junction control signal has been changed to display a yellow aspect when a route

requiring the junction indicator to be illuminated is set.

Since 2005, RAIB has investigated 58 incidents involving track workers and moving trains. Of these, 10 resulted in deaths and 12 in injuries. The SoL showed that

the safe system of work in place during these incidents included 24 instances of unassisted lookouts, 12 possessions, and 12 line blockages. It identified the following concerns:

» Planning work.

» Quality of site leadership.

» Supervision and monitoring of track workers.

» The way information is presented to track workers.

» Standards of lookout working.

» Staff installing possession protection equipment.

» Management of contingent labour.

» Staff willingness to challenge unsafe practices.

The fatal accident at Surbiton in February 2021 was followed by five track worker near misses, investigated in 2022. The Surbiton report showed that the individual killed was working outside the protected area and recommended action to keep track workers within safe limits. It also recommended that Network Rail review working practices to understand reasons for non-compliances. This, and previous reports, highlighted the need to reduce the amount red zone working.

FIGURE 2 - Cab video shows track worker near miss at Paddington CREDIT: RAIB

RAIB’s annual report notes that improved technology and planning reduce the occasions that workers are on track when trains are running. However, as RAIB’s chief inspector Andy Hall notes: “whether working in planned red zones or not, lower-level risk controls relating to safety behaviours and site safety leadership remain important, if we are to avoid the type of near miss we continue to see, that one day may turn out to be another tragedy.”

FIG 1

FIG 1

RailStaff has been championing the rail industry’s workforce since 1997.

As well as getting to the heart of ‘what you need to know’ each month, its team of writers focus on the latest developments in:

• Health

• Safety

• Wellbeing

• Careers and training

We also cover stories that celebrate the great achievements of staff.

Such is the freely-distributed magazine’s success that the only industry-wide people recognition scheme, the RailStaff Awards, was launched in 2007, and has been held ever since.

Request a free subscription at www.railsubs.com

Call 01530 816 444 or visit www.railstaff.co.uk for more information

Weather related incidents considered by RAIB in 2022 were a train hitting a fallen tree at Balderton in November 2021 and a train running over a washed-out line at Haddiscoe in January 2022. Prior to the Balderton incident, RAIB found that Network Rail had not considered all relevant meteorological data. Though these incidents only resulted in minor damage, the tragic Carmont accident, on which RAIB published its report in March 2022, highlighted the dangers of bad weather.

structures, trains hitting objects, unsupported track, and brakes affected by ice and snow.

The annual report notes that modern weather forecasting can predict exceptional events, allowing operators to implement focused precautionary measures to reduce the need for blanket speed restrictions over areas that are not at risk.

The importance of clear communications when imposing such emergency speed restrictions was emphasised in a safety digest issued in November 2022 following various overspeeding incidents. This highlighted the need for appropriate methods, including available technology, to ensure that weather-related speed restrictions reached the staff who need to act upon them.

passenger fell off a platform which did not have tactile edge markings.

With several million people getting on and off trains every day, ensuring that everyone is clear before departure is a challenge, especially for trains with repetitive stops at busy stations. Hence RAIB reports have recommended measures to support drivers to maintain attention and awareness.

RAIB’s weatherrelated events SoL refers to 19 reports concerning management of earthworks and structures; response to adverse weather; snow and ice; and heat. These show the varying consequences of bad weather events including track buckling, scour undermining

RAIB’s SoL of platform-train interface incidents refers to 15 such reports at train and tube stations and tram stops. Of these, 11 were trap and drag incidents and, in three cases, a passenger fell between train and platform. In a further incident, a visually impaired

Reports have shown that the detection of trapped objects by door control systems needs to be improved. Investigations have shown that drivers and train dispatch staff were unaware of this problem and so relied on the door interlock indications to confirm that nothing was trapped. In one accident a driver did not realise that a trapped passenger’s hand could not be detected by the door interlock.

Another misconception is that, as shown by RSSB research, 58% of passengers mistakenly believe that, like lift doors, train doors will reopen if they are obstructed. In one case a passenger became trapped when she placed her hand between the closing doors in an attempt to re-open them as she attempted to board the train.

FIGURE 3 - Carmont accident in August 2020 CREDIT: RAIBRAIB’s User Work Crossing (UWC) SoL shows that it has published 24 UWC reports which highlight the following concerns about Network Rail’s 2100 user worked crossings:

» Briefing by authorised users.

» Signage.

» Signaller’s judgement.

» Signaller’s understanding of type of vehicle.

» Power operated gates.

RAIB issued four reports concerning UWCs and footpath crossings in 2022. The incidents at Coltishall Lane and Kisby both showed that users did not know how to use a UWC. As well as reviewing signage, RAIB recommended that Network Rail, with ORR and DfT support, should review current arrangements that required authorised users to brief potential crossing users given the increase in delivered goods and services. As Andy Hall noted: “we still have a nineteenth-century concept in a twentyfirst century environment.”

Both reports on the fatal accident at Lady Howard footpath level crossing and near miss at Farnborough North level crossing showed that insufficient action had been taken to mitigate the known high risk at these crossings.

Though steel wheels on steel rails make for a highly energy efficient railway, moisture and other contaminants can significantly reduce the friction between wheel and rail. Two quite different consequences arose from the two low adhesion incidents that RAIB considered in 2022. At Pencoed and Llanharan in March 2021, severe wheel flats on a freight wagon caused track damage as wheels locked after a normal brake application due to low adhesion.

A serious incident occurred on at Sailsbury Tunnel junction in October 2021 when a passenger train was unable to stop and collided with another train at about 54mph. This was the first collision between passenger trains at speed that RAIB has investigated since its formation

in 2005. It resulted in a driver being seriously injured and 13 passengers taken to hospital. Had the train collided with one travelling in the opposite direction, the consequences would have been far more severe.

FIGURE 4 - Farnborough North footpath crossing CREDIT: RAIB

FIGURE 5 - Scene inside Sailsbury tunnel CREDIT: RAIB

FIG 5

FIGURE 4 - Farnborough North footpath crossing CREDIT: RAIB

FIGURE 5 - Scene inside Sailsbury tunnel CREDIT: RAIB

FIG 5

RAIB’s interim report, issued in February 2022, confirmed that, for two miles before the collision, the railhead was contaminated with crushed leaf material. It considered that this reduced the coefficient of friction close to an exceptionally low value of 0.02. Rail Engineer has featured various reports on the work of Adhesion Research Group. RAIB’s investigation into the Sailsbury Tunnel Junction accident will no doubt provide added impetus to this group’s essential work.

With the passage of time, most in the industry today did not experience the shock of learning how a loose wire caused the catastrophic Clapham Junction accident in 1988. This wrong side failure (WSF) was particularly disturbing for signal engineers who responded by producing new signalling staff handbooks on works testing, maintenance testing, installation, and design. These incorporated all the lessons from the Clapham accident and were supported by enhanced training. At the time all concerned knew why these handbooks were so important.

In 2022, RAIB considered two WSF incidents. In September 2022, it published its report into a derailment at Dalwhinnie caused by a wiring error when a points machine was replaced nine months earlier. In October 2022, a train running under green signals at Wingfield was unable to stop when it unexpectedly encountered a red signal. This occurred

after the signal had been disconnected for planned maintenance work. Fortunately, there were no significant consequences from either of these incidents.

RAIB’s annual report suggests that the lessons of Clapham are being forgotten. To highlight these, RAIB recently introduced a SoL on WSFs. This considers the Dalwhinnie and Wingfield incidents as well as a 2016 irregularity at Cardiff East Junction, a 2017 collision at Waterloo, and loss of signalling data on the Cambrian Coast line in 2017. It identifies the following areas of concern: commissioning signalling projects, maintenance renewals and assurance of software products.

Poor freight wagon maintenance has been a matter of concern in several RAIB investigations. The freight train derailments SoL references 22 RAIB reports on freight train derailments and two on track damage caused by freight trains.

Poor wagon maintenance was further highlighted when, in January 2022, RAIB published its report into the Llangennech freight train derailment as reported in issue 194 (Jan-Feb 2022). This recommended a comprehensive review of freight wagon maintenance management. During this investigation RAIB issued an Urgent Safety Advice on the need to manage the risk of malfunctioning wagon braking systems.

Since the Llangennech derailment, there have been freight train derailments at London Gateway in December 2021 and Pettril Bridge Junction in October 2022, for which reports have yet to be published.

The SoL refers to five cases of freight train derailments being caused by track condition and, in particular, the failure of rail fastenings on tight radius curves. It also showed that three freight train derailments had been caused by uneven loading.

The SoL on the safety of on-track plant (OTP) and trolleys considers: Road-Rail Vehicle (RRV) braking; operator competence; vehicle conversions; and trolley/ trailer braking systems.

RAIB has published nine reports on RRV runaways which almost all concern ineffective braking during on and off tracking of ‘high-ride’ RRVs. These have rail wheels with a hub that is driven/braked by the machine’s rubber-tyred road wheels. If such RRVs are not properly on-tracked, contact between road and rail wheels may be lost which can result in a runaway.

FIGURE 6 - Positions of road and rail wheels on OTP after runaway at Bradford in June 2018 CREDIT: RAIB

Following a spate of such incidents, all such RRVs were fitted with a Direct Rail Wheel Braking (DRWB) system. However, this did not entirely prevent such incidents as shown by the RRV runaway at Belle Isle in May 2021 which was due to an ineffective DRWB system due to a valve left open following maintenance.

The RAIB reports into RRV collisions at Cholmondeston in September 2018, Rochford in January 2020, and Ramsden Bellhouse in May 2021 concluded that current rules lacked clarity about who was in charge of the safe movement of track plant. These reports recommended that Network Rail should review and clarify the roles of those responsible for plant operations in possessions and work sites, to avoid duplication of responsibilities and minimise confusion between roles. This recommendation is still being progressed.

The Cholmondeston report also found that there was very limited visibility ahead, when the RRV was driven in reverse. It noted that RRVs spend an equal amount of time travelling in both directions and recommended that the relevant controls need to consider practicalities of such limited visibility.

Runaway hand trolleys and a trailer were considered by reports into incidents at Haslemere in September 2011, Raven Crossing in November 2014, Hope in May 2017 and at Ramsbottom in March 2018. The issues raised by these reports included poor brake maintenance, standards not considering whether the brake is a parking or service brake and that planning had not adequately considered the gradients on which this equipment was to be used.

The SoL on braking system integrity considers trains that cannot stop, stopped rail vehicles running away, and derailments due to wagon braking faults. This last topic essentially overlaps the freight train derailments SoL. For two of the incidents of trains not being able to stop, the locomotive provided the only brake on the train. A freight train passed a signal at danger at Crofton West Junction in May 2020

because its wagons had no brakes as, after a brake test had been undertaken the night before, the locomotive had been used for instruction and the instructor had left the brake pipe and reservoir pipes isolated.

In August 2019, the driver of a sleeper train was unable to control its speed through Haymarket East Junction and was unable to stop at Edinburgh Waverley. This was an incident with potentially catastrophic consequences. RAIB investigation concluded that that the Brake Pipe Isolating Cock (BPIC) had almost certainly been inadvertently closed whilst the electrical supply plug was being connected when the train was split at Carstairs. It made recommendations concerning brake continuity testing and preventing unintended operation of the BPIC.

The locomotive, ‘Vale of Ffestiniog’, on the heritage narrow gauge West Highland Railway entered a single line section without authority in April 2019 when it was unable to stop as it descended a 1 in 40 gradient through Beddgelert. This was found to be due to a brake system modification made 18 years previously.

FIGURE 7 - 600mm gauge ‘Vale of Ffestiniog’ locomotive CREDIT: RAIBThe importance of ensuring parking brakes are applied was shown by the runaways of a rake of 22 wagons running away at Toton sidings in January 2021 and an unattended engineering train at London Liverpool Street station in October 2022.

Another SoL considers incidents during abnormal events. These concern passengers detraining, usually of their own volition, and safety incidents from poor communications. Although RAIB did not have to consider any such events in 2022, this SoL is still highly relevant.

Drivers only very rarely encounter incidents in which their trains fail and become stranded. When this happened in May 2011 at Kentish Town, in March 2018 at Lewisham, and in July 2019 at North Pole Junction, passengers decided to detrain themselves onto the live railway. When a train was stranded 30 metres from Peckham Rye station in November 2017, a decision was taken to detrain passengers who were then close to the live conductor rail.

RAIB found that in such cases drivers were sometimes poorly supported by the control room and made poor decisions as they were overwhelmed by events. It also concluded that operational interfaces between different train operating companies, signallers and control offices were poorly managed. It recommended enhanced training and exercises to enable operating staff to effectively manage train stranding incidents and recognise that such incidents on a busy urban railway can rapidly create an unsafe situation.

Reports on unsafe situations during abnormal

events were a near miss between a train and a driver who was on the track examining his train at Stafford in March 2018, and a driver moving a train past a red signal without the signaller’s permission at Bethnal Green in April 2018. Both incidents were due to poor communications.

RAIB’s annual report is a good and essential read. As well as its many specific safety lessons, it highlights some key general points. Historically, railways have improved safety by learning from accidents, yet some recent accidents suggest that lessons from the past are being forgotten. Another issue is that, in a complex environment with competing pressures, it can also take too long to mitigate known high risks.

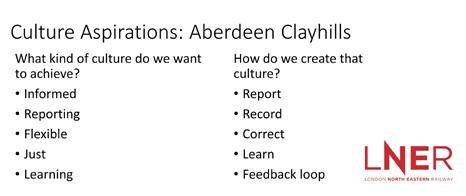

It is also important that those responsible understand what is actually happening rather than what they think should be happening. This needs a culture which encourages a flow of information from the sharp end. Understanding what does and can happen is essential if risk is to be effectively managed, as compliance with standards, in itself does not guarentee safety.

RAIB’s SoLs are also an essential read for those concerned with their specific themes. Its reports on each incident are also a good read, though of necessity these are comprehensive lengthy reports. Rail Engineer understands the pressures on everyone’s time but hopes that this feature encourages its readers to read the RAIB publications applicable to their work given the importance of understanding and implementing the lessons in RAIB’s publications.

Protect your staff from pit falls

Easily retrofitted to any pit with a light recess

No civils work required

Minimal working space lost

Air operated

Quick & easy operation

The Premier Hinged Cover (patent No. E2 886-747-B1) is an air operated fall restraint made up of 2.5m steel mesh panels. The panels are operated by pneumatic cylinders connected to a central control box for an easy one person operation. The stairs of the pit are covered by individual sections which are manually lifted, and have the additional benefit of acting as a hand rail for ingress and egress.

The Premier Hinged Cover enables clients to protect their staff with minimal disruption whilst keeping the maximum working space, and can be installed on existing steel, concrete or block pits.

In May 2023, a month after the ‘Train depots for today and tomorrow’ conference (see page 26), Rail Partners and Rail Delivery Group hosted a fleet introduction and cascades lessons learned event. Around 8,000 new vehicles, not all yet in service, were ordered by many operators in the 2010s. This resulted in the cascade of older vehicles to other operators. With such a big programme, some problems were inevitable.

Mark Molyneux, national fleet performance manager, Rail Delivery Group (RDG), set the scene, discussing the well-publicised problems of the May 2018 timetable. This debacle put the rail industry’s problems into sharp focus and the delay to fleet introduction kept rail in the headlines. He reported that the biggest cause of delay to the industry Public Performance Measure were ‘fleet related’ issues. Fearing that the influx of new trains would cause further harm, RDG commissioned the report ‘Risks to Network Performance from New Train Introduction’.

This report sought to address the questions: Is there a risk to system performance from unreliability of new rolling stock? Is there a risk to timetable delivery from late introduction of new and refurbished rolling stock? The report identified factors increasing these risks and proposed actions and mitigations to ease the short-term situation and make major improvements for later projects. Mark reported that the output from an RDG-convened New Trains Colloquium in October 2018 and the above report led to

the development during 2019 of the RDG Guidance Note ‘New Trains – A Good Practice Guide’ that was first published in March 2020.

Mark reported that, despite this worry, the average Miles per Technical Incident (MTIN) has remained remarkably consistent since 2018. He had also examined the growth in MTIN performance over the first year in service for each new fleet introduced since 2018. Some fleets have achieved MTIN significantly better than the national average, whilst others have delivered slower reliability growth. See FIGURE 1.

The difference between suppliers is significant. One supplier’s fleet exceeded the national average MTIN in 15 months from entry into service, whilst another took over 54 months for just one of its fleets to pass the average MTIN figure. See FIGURE 2.

Of course, the context of each fleet varies and there are differences between new designs, duty cycles, and follow-on orders for established designs.

Steve Clarke, senior project manager at Angel Trains, described a collaborative project with Hitachi in which 19x5-car trains were supplied to TransPennine Express (TPE) and 5x5-car trains were supplied to Hull Trains, both financed by Angel Trains. They were ordered in October 2016 and delivered in 2019-20. Although similar to the class 802 units supplied to GWR, these have a larger fuel tank, higher output engine, bigger rheostatic brake, and a revised catering area. The bodyshells were to be built and painted in Japan, and assembled in the UK, but, in fact, seven units were fully built in Japan, the remainder assembled/ finished at Hitachi’s plant in Pistoia, Italy, and all were commissioned at the UK plant in Newton Aycliffe.

FIG 1

FIG 2

FIG 3

FIG 1

FIG 2

FIG 3

Steve said that the collaboration was grounded on these key behaviours: a shared sense of success, a shared fear of failure, relying on each other, and holding each other accountable.

“If everyone performs well, we will all succeed...but if one fails, we all fail,” said Steve. He added that trust in each other was essential. Steve told the audience that part of the success was to give the contract a voice and understand what it was trying to accomplish.

People tend to focus on the parts of contracts that emphasise procedures if things go wrong, but Steve stressed the importance of maintaining a preventative mindset, as well as collaborative behaviours when corrective action was needed.

A joint risk register of project risks (which focused on things that might throw the project off course rather than financial or safety risks) was in place, with mitigation activities managed by the organisation best placed to do so. For example, TPE and Hull Trains managed gauging.

A similar approach was taken for other interfaces, with one organisation in the lead but the others having actions. Collaborative project management works, as Steve concluded. It requires hard work and care, but all must want to work together. As one delegate put it: “you can’t collaborate at someone”.

Martin Beable, engineering director at Greater Anglia (GA), talked about the pitfalls of introducing their new trains. GA’s 2016 franchise agreement provided for the then current fleet to be replaced by Alstom

Class 720 and Stadler Classes 745 and 755 units. The original plan showed that all these would be in service by the end of 2020 but there were delays, mostly caused by Covid. Martin showed the actual timeline and reported that the last of the legacy fleet had now been withdrawn. Another change was to make the suppliers responsible for maintenance, with many staff transferred to them under TUPE, and depots had to be extensively rebuilt as discussed in the Depots article elsewhere in this magazine. The split of responsibility between GA and the suppliers was slightly unusual, as shown below.

Martin stressed the importance of constant reassurance for staff who knew they were to be transferred up to five years before the event happened. Martin described a lesson learned from Norwich Crown Point depot. Although both GA and Stadler personnel were on site and strategy and responsibilities had been set out clearly in contracts, physical and cultural walls made meaningful collaboration difficult, and silos emerged. Martin commented that in practice, the contract did not cover all situations and was too commercially led. GA and Stadler implemented joint initiatives, which should have been in place from the start, with a one team approach under a ‘putting the passenger first’ banner.

Possibly the biggest challenge of all was capacity, particularly during the Stadler FLIRT fleet introduction. Martin said that Stadler was delivering as fast as it could, but, while the depot was managing commissioning and cascades, capacity was reduced while the site was rebuilt and there was nowhere to put the new trains. In addition, there was only three months of overlap between receiving new trains and handing back the old ones, leading to last minute deals with ROSCOs and the train operators who were supposed to be receiving the cascaded fleets. This led to the most important and frequently revised working document, the fleet cascade plan, and the weekly cascade meeting.

Martin gave his own mental scoresheet for the transition in exam style, resulting in an overall ‘pass’ mark for their new fleet introduction.

Neil Bamford, fleet director at East Midlands Railway (EMR), turned to the subject of fleet cascade. This was not unlike GA, where eight different fleet types become three but, for EMR, only one fleet is new. The incoming fleets were the Class 360 from GA and 2- and 3-car Class 170s from Govia Thameslink Railway, West Midlands Railway, ScotRail, and Transport for Wales. In addition, as stopgaps before the Hitachi Class 810 units arrive, EMR’s HSTs were replaced by redundant (but more compliant with the NTSN for People of Reduced Mobility) HSTs from LNER and ex-Hull Trains Class 180s. Outgoing Class 15x units were cascaded to Northern or are going off lease.

To add to the mix, EMR was working with four ROSCOs (Angel, Eversholt, Porterbrook, and Rock) and a huge amount of legal documentation was involved, including 15 leases, six subleases, and literally hundreds of extensions, amendments, side letters and associated documents, handover/hand back documents, conditions, and liabilities. This task alone was time consuming and expensive, with each ROSCO having a different approach.

While all this was going on, performance had to be maintained. For the cascaded units, timely technical and traincrew training needed to be undertaken, tools and equipment put in place, technical documentation needed to be accurate and understood, and a float of material obtained. In addition, said Neil, depot capacity and throughput was a challenge and delayed refurbishments, such as Class 360, didn’t help. One might think, mistakenly, that all the Class 170 units transferred in to EMR would fit easily with the existing fleet. Besides obvious things such as livery and pre-recorded announcements, there were all sorts of differences - see table below – some of which could be corrected quickly and others which took longer. In the meantime, trains still had to be brought into use.

To mitigate risks, train and fleet staff visited Selhurst, Tysley, and Cardiff Canton to see and understand the configuration of the various units. Despite that, differences between inherited fleets have caused operational incidents. Extensive briefs were provided to mitigate further risks and safety validation panels have been held.

FIGURE 5 - EMR, TfW and Southern liveried class 170 units. Note Dellner coupler on the ex Southern unit (Aidan Morland/Beth Mack)

FIGURE 5 - EMR, TfW and Southern liveried class 170 units. Note Dellner coupler on the ex Southern unit (Aidan Morland/Beth Mack)

Neil reported that introducing the Class 360s was relatively straightforward, partly because they were to operate a new service. A sub lease was put in place with sister company GA and Siemens remained as maintainer (under a new TSA contract). Initially, only 14 from 21 units were required and reliability has steadily grown. Two big issues are the outstanding refurbishment and provision of maintenance facilities. There has only been limited upgrade work at Bedford Cauldwell depot and units still need to be loco hauled to Northampton, Kings Heath once or twice per week. But further upgrades at Cauldwell are due to be complete by August 2023 (overhead crane, lifting jacks etc.) to reduce the reliance on Kings Heath.

In summary: the ever-changing plan had knock-on effects to internal resource and the supply chain. Neil said that there must be clarity and trust about handover and hand back. He also wondered whether contractual process and methodology need to be so complex?

Returning to new trains, Liam Hockings, new fleet introduction manager at Avanti West Coast, covered the multitude of issues to be dealt with when a new fleet is being introduced. He identified 69 separate activities, with assurance, training, and compatibility representing a minority of the activities.

Moreover, as non-tilting units, they will currently be limited to 110mph on the fast lines. Avanti and Network Rail are working on the Multiple Unit (MU) Line Speed Enhancement project, to maintain route capacity with non-tilting trains. Liam said that there will be no physical track works, just new signs showing, for example, ‘MU 125’, and detailed planning is ongoing to integrate the driver training required for the new trains, the new speed profile, and the introduction timetable whilst maintaining the train service. The work also includes a detailed risk assessment to understand and mitigate the risks associated with operating a mixed fleet with potentially different means of managing the safe speed of the train.

Liam outlined the validation work to show that 42 stations with over 200 platforms, many shared with other fleets/ operators, were ready for the new trains but this was complicated by three different train lengths being introduced, and the positions of multiple wheelchair, cycle, and catering doors needed to be considered for all train formations. Liam said that 30 miles of walking with a measuring wheel was required to complete these assessments.

Station stop signs are an issue, with some locations needing many. At Milton Keynes Central, for example, the two operators will be operating trains from three cars to 12 cars with lengths between 72 and 265 metres. Another consideration was signalling, e.g., making sure trains don’t stop with a wheelset over an axle counter. Liam reported that validating the catering vehicle layout is more complicated

The Classes 805 bi-mode and 807 electric Hitachi Inter City Express trains are nearly standard units, but they are new to Avanti and all staff using them will require training including maintenance staff from Alstom.

than one might think. Issues include: does it meet the expectations, has the catering offer changed since the train was specified, do the coffee pots fit and are the chillers big enough for a reasonable stock of sandwiches?

Renowned as the global market leading depot protection system, the SMART DPPS™ delivers physical protection from vehicle movements to rail depot staff whilst providing visual and audible warnings.

The Smart DPPS™:

• Protects staff and equipment

• Ensures safe and controlled movement of rail vehicles into and out of the depot

• Allows train maintenance operations to be conducted without endangering the safety of staff or damaging infrastructure

It is:

• Fully configurable, flexible and functional

• Proven in use and installed globally

• Capable of interfacing with third party equipment including signalling systems.

• Adaptable to the safe requirements of the depot

New trains affect Network Rail infrastructure, of course, and might have an impact on other operators’ activities. Organisations introducing new trains into service or moving existing trains to a new route have several legal duties to undertake including demonstrating compatibility with the lines on which they will run.

David Galloway, network technical head for System Compatibility and Traction & Rolling Stock, Network Rail (NR), outlined some of the issues. Duty Holders (i.e., Train Operator for trains, NR for, e.g., new stations) must demonstrate their changes are safe, comply with relevant international, national and railway specific standards and are compatible with the rest of the system, though, in general, fleet cascades generally need only consider compatibility.

Considering new trains, train operators sometimes delegate responsibility for some of the work to the train supplier. Network Rail also must satisfy itself that trains are compatible with its infrastructure, so it is important that organisations collaborate, a process, David said, best started early with open dialogue between affected parties. Railway and general health and safety law imposes the duty of cooperation between Duty Holders, but to make the railway work, there must also be cooperation with ROSCOs, manufacturers, neighbours and others who are not specifically identified in the law.

Whilst there is plenty of guidance on what factors to consider, there cannot be a definitive list. David cited 24 relevant Group and Railway Industry Standards that usually need to be considered. Key topics include power, signalling and train protection, gauging, acceleration/braking curves, track wear, selective door operation and electromagnetic compatibility.

As well as demonstrating compatibility, duty holders have to demonstrate safe integration; making sure that a change (e.g., a new vehicle type, network project, subsystem,

component, software, procedure, organisation) fits into, and does not create an unacceptable risk for, the resulting system.

Rich Fisher and Maria Cliff, from the Great British Railways Transition Team looked at future rolling stock, depot,

kilometres of electrification. He said that it would be wise not to assume that this plan is the only solution. He said that a balance of rolling stock and infrastructure solutions will be necessary, and he anticipated that rail will need to use offsetting and bio-fuels to demonstrate net zero carbon beyond 2050. That said, electrification scenarios have been

Rich presented a graph showing what type of traction might replace the diesel fleet over the next nine control periods (45 years). This programme would see the virtual elimination of diesel only passenger trains but would retain a significant number of bi-mode diesels (or other fuelled internal combustion engine). He said that hydrogen has limited role, due to cost and energy density, but this could be revised if technology develops. He added that electric passenger trains outperform diesel which brings carbon gains through modal shift and benefits all customers whilst delivering lower operating and maintenance costs.

Rich’s views on trains for the future focussed on improving from the short termism of specifying new trains to win a franchise. He added that the supply chain has been getting inconsistent messages from the industry, hindering investment in innovation, and increasing costs. He wants the emerging strategy to consider trade-offs and choices (e.g., seats vs luggage vs bikes) and to quantify them where possible. There will be a vision to help the supply chain deliver for both funders while meeting the needs of passengers, but the strategy will not be about designing new trains, more it will be about linking the long-term strategy to existing good practice.

Maria considered some near-term decisions required, specifically the ‘legacy’ DMU fleet (Classes 150, 155/6, 158/9, 165/6) which are nearing life expiry. Although some operators have begun to engage with the market for replacement trains, she said “a network-wide vision will help support individual operators and ensure best value decisions”. That said

the default position is that most replacements will be diesel powered or, in a small number of cases, batteries. Options being evaluated include bringing younger off lease diesel trains back into service, selective life extension to defer replacement, and/or accelerate deployment of battery trains (new or upcycled) to low-risk routes.

Maria and Rich expect that with better planning and more homogeneity, trains might be introduced more efficiently.

For your writer, key messages from the event included: introducing a train fleet isn’t just an engineering challenge, it’s a major business change programme for the operator and others in the industry. As Liam Hockings said, new trains don’t put themselves in service, people do, and the importance cannot be overemphasised of detailed planning and investing the time to build open and honest, collaborative relationships between operators, manufacturers, rolling stock owners and infrastructure managers so challenges can be shared and solved. Finally, there are still over 1,000 vehicles from the pre-2020 orders to place into service and this means that there is still plenty of opportunity to apply lessons learned here and from the RDG Guidance Note: New Trains – A Good Practice Guide.

Thanks to Mark Molyneux of RDG and Neil Ovenden of Rail Partners for the opportunity to attend and report this industry event. Photos and other illustrations provided by presenters unless otherwise stated.

Rail Partners, the trade body for train operators, organised the ‘Train depots for today and tomorrow’ event to bring train operators, suppliers, and other industry stakeholders together to discuss how to improve depot safety and productivity. It covered the importance of depots and the constraints within which they work, something not fully appreciated but critical to the performance of the railway. Late starts from depots, for example, affect network reliability.

Depots are safety critical environments and, although new build depots offer opportunity to get things right and improve safety, provide a better working environment, and complement the local landscape, the process of upgrading a depot can introduce safety challenges. The event also provided opportunities for sharing good practice and, looking to the future, considered plans for HS2 and how robotics can improve productivity and reduce workforce exposure to dangerous, dirty, unpleasant, or repetitive tasks, something covered in separate mini articles.

Neil Bamford, fleet director at East Midlands Railway and formerly, West Midlands Trains (WMT), opened the event stating several challenges. Clearly, depots are there to achieve top class safety (both in terms of the depot production environment and the rolling stock itself), train performance, and train presentation. On some projects, he observed that civil engineers have, perhaps, “held sway” when building or upgrading depots and the engineer/ operator voice has not been heard loud enough. He also said that Network Rail route studies did not always consider the criticality and importance of train depots and outstations with the desired output of consistently delivering excellent operational performance.

Neil worried that engineers always find a way to deliver the service in the end, but asked: “Do we compromise too much, relying on a make do and mend approach, leading to 363 days (excluding

Christmas Day and Boxing Day) a year of work arounds and the consequential inefficiency and increased cost?”

He emphasised the importance of planning and management, making sure that required downtime for maintenance, servicing, and train presentation is delivered and that delays leaving depot (code MP701A, known as 701A) are correctly attributed so that the correct root causes are identified, understood, and acted upon. He added that we must move to depots that operate more efficiently and Train Servicing Agreements that are properly managed.

His final words were: “if you plan to run at 100% capacity then you’ll plan to fail; you must build in some contingency and headroom.”

Several speakers rightly highlighted safety; the prerequisite of all other activity. Neil Bamford drew attention to the fatal accident at Tyseley depot on 14 December 2019 where a driver was killed when passing between two units, just 350mm apart. The RAIB recommended improvements to hazard identification, risk assessment, and WMT’s safety assurance processes.

Dave Baston, in charge of Norwich Crown Point depot, described the safety challenges of an influx of construction workers unused to working in depots, together with another group of nonEnglish speakers involved in the commissioning and support of their new trains and completely unaware of UK safety law and practice. As a result, he had to put in place additional management resource just to help to manage these activities safely.

Seamus Scallon, operations and safety director for First Rail, cited the Tyseley accident as part of the catalyst that led to setting up a Depot Working Group. This and three other depot fatalities in very different circumstances reinforced the need to improve depot safety. There had also been expensive damage to trains in depot derailments and, in January 2020, the Network Performance Board challenged depots

to improve wrong formation and 701A performance. At that time, the depot delay incident count across the network had increased by 86% since the start of Control Period 5 (CP5).

Seamus summarised the challenges. There had been limited industry focus on depots (including yards and sidings) and there was no clear industry-wide picture of risk, safety, and performance. They were often treated as a black box i.e., what went on inside was less clear. He added that a factory type environment with moving trains was an added risk and there was limited good practice guidance. The rail industry’s health and safety strategy, Leading Health and Safety on Britain’s Railway (LHSBR), recognises that there is no clear industry-wide picture of risk and safety performance in depots and calls for improved industry-wide understanding of depot risk.

In response, train operators created the Depot Working Group, a task and finish group reporting to the Passenger Operators’ Safety Forum. Initially, it included joint working between RSSB and The Rail Delivery Group but transferred to Rail Partners although retaining the RDG and RSSB links. With the challenges of Covid and lockdown the group rarely met face to face, but a great deal of useful work has been done. RSSB carried out a deep dive on depot safety – mostly slips trip, falls and

issues such as a peak in accidents after the morning peak. The Depot Working Group has enabled improved collaboration between depots and has developed a Depot Good Practice Guidance Note (on the RDG website). There is also a Train Depot Good Practice Guidance note 07 available on request from Rail Partners.

RSSB is currently working on understanding practical depot capacities, ensuring the timetable works for depots and depot performance benchmarking.

Seamus added that RSSB has delivered many activities such as economic modelling and bow tie safety/ hazard modelling.

Seamus said that the task and finish group has completed its work. There is much work still to do and will now link more closely with LHSBR and there is an opportunity to widen the work to HS2 and freight. He concluded that collaboration between train depots is still needed, and Rail Partners will link depot managers together via events, workshops, and webinars.

Peter Williams, fleet and performance data manager at Avanti West Coast, took up the theme of Learning Lessons from the Past. Peter also chairs the subgroup aiming to reduce 701A delays of trains leaving depots. His theme was that depots were the ‘Cinderellas’ of the railway (according to the Collins Dictionary: “a poor, neglected or unsuccessful person or thing”).

This view came about because depots are not considered to be part of the ‘main line network’ with an inference of not being important. They tend to be treated like a black box with top management only interested in ‘what’ and not in ‘how’, and they are expected to work miracles. As Peter said: “Management thinks depots have supernatural powers to magically reset the clock at midnight, because irrespective of the carnage on the network the day before, the following day all the trains needed are expected to be offered for service on time, fully repaired, reliable, and clean”.

Peter said that depots are not adequately considered in timetable development and that not all Empty Coaching Stock (ECS) moves are even timetabled. “How can the depot plan for when trains are going to arrive?”, he asked. He added that some new trains have been ordered without any clear depot maintenance agreement and there have been examples where the trains are too long to be accommodated satisfactorily in the nominated depot(s). These two issues came as a shock to your writer with his 40+ years’ experience in London Underground, where trains are always timetabled for all moves, and where depot alterations are always part of new train procurement projects. In the general discussion, the need for closer working between depots, TOC operations, Network Rail Operations and Network Rail timetable planners was echoed by most present, including representatives from Scotrail where the TOC/ Network Rail relationship is closer than anywhere else in Great Britain.

FIGURE 1 - Peter showed a 2019 graph illustrating the 86% increase in 701A incidents since the start of CP5.

Although 701A incidents are low compared with other causes, he said, they often trigger knock on delays. The delays fell to a very low value during the Covid lockdowns and have gradually risen since, but not to the same level as in 2019. Peter’s subgroup’s tasks were to review the national data and work towards providing the necessary insight in relation to filling the gaps in the depot performance data; consider and propose how the 701A data could be used to ‘fairly’ compare depot performance; consider and propose how depot performance can be improved; reduce the number of 701A incidents; and develop good practice proposals.

One team in his group is developing a methodology to determine depot capacity.

For example, a simple fan siding set might be capable of operating successfully if all sidings are occupied, but a depot might need to leave some roads vacant to allow trains to be moved around for servicing, fuelling, maintenance etc., and if those roads are filled, the depot will not be able to operate.

Some depots have defined Depot Rules (not unlike rules of the route/plan) that outline what each depot can: accommodate (frequency of incoming trains); store (capacity); maintain (maintenance activities/ requirements); and deliver (times/ frequency of departing trains). These rules will be used to confirm that new or changed timetables are compatible with these requirements.

Peter asked attendees to help raise the priority of depot needs in relation to decision making, develop and enforce Depot Rules, review delay attribution processes, and make sure that incidents allocated to a depot are really within its gift to resolve.

Dave Baston talked about Safety during Change drawing on his experience managing Norwich Crown Point depot which formerly looked after the London-Norwich loco hauled Mk3 carriage push pull sets and a motley collection of diesel multiple units.

Earth).

When the current Greater Anglia contract started, it was announced that all of these (and the Stansted Express) were to be replaced by 20, 12-car Stadler EMUs, 24 4-car and 14 3-car diesel electric bi-mode regional units, all from Stadler. They represented a significant change in technology and, for passengers, probably the single biggest innovations were train floors which were more or less level with the platforms and automatic sliding steps to bridge the gap between train and platform. Dave explained the pain involved with such a massive change, the more so because Crown Point was not originally planned to be the depot for these trains as the proposed site in Manningree proved to be unsuitable.

He summarised the depot team’s journey in three stages:

» Pre-October 2016 – Evolution.

» One team, stable facilities, availability matched to service, high performance, stable franchise environment.

» 2016-2022 – Revolution.

» Split teams (some existing staff transfer to Stadler under TUPE), major depot change, major fleet change, low performance.

» Present – Evolution.

» Common goals, stable fleet, stable facilities, marginal gains, one team.

FIGURE 2 - Norwich Crown Point Depot from above (GoogleDave highlighted several issues with interfacing the new trains with the depot, not least was the sheer length of the 12-car trains at nearly 237 metres, needing very careful set out of all the depot touch points – toilet and sand servicing points, for example – as well as the compatibility of wash plant brushes with a new train where the bodysides are lower than on the trains they replace. In addition, the first new depot facilities needed to be available before the new trains first ran and grew as the operational fleet grew.

Dave said that they were often “struggling to keep up” and “a high level of maths and planning was required”. But, in the end, there was a big gap between theory and practice. They found that servicing a 12-car train was a lot harder, and they sought and used alternative sites (Derby Etches Park, Ilford, and Bounds Green) to reduce the maintenance load for the legacy fleets when 70% of the maintenance sheds were lost to construction.

Dave described several of the bigger changes. On the older trains most of the maintenance was carried out from underneath, and vehicles were lifted on jacks for bogie changes. On the new trains, roof access was required for equipment displaced from underfloor locations because of the lower floors, side access to exchange diesel generators, and a bogie drop to facilitate bogie exchange on articulated vehicles that are not easy to split. Also, and inevitably, the shore supplies were different.

Managing all this safely proved to be a major task as the construction work fell under the CDM regulations and physical, interface, and management responsibilities between site management and the construction contractor, had to be defined.

There were many visitors to site including the new maintainer and commissioning teams (TSA and MSA), the transferred staff now working to the new maintainer’s rules, many construction contractor workers (in excess of 150 not familiar with depots and the OHLE environment). As Dave put it, “Piccadilly Circus moved to Crown Point”, but he noted that his responsibility as depot facility operator remained and there was a high risk to safety and operations. His advice for managing visitors included:

» Put in dedicated contractor controllers.

» Have a dedicated and separate safety team to take ownership of and investigate any accidents, incidents and near misses.

» Robustly audit and demand feedback.

» Check and approve work package plans, safety packs and lift plans.

» Make time to be out on the shop floor; don’t rely on the mountain of paper.

» Communication/briefing and toolbox talks to staff are vital.

» Have a robust induction programme (many visitors from outside the industry mean you need to act swiftly before any accidents occur).

» Have the confidence to remove/ban from site people who don’t behave safely.

Dave’s conclusion was that anyone managing a large fleet cascade will have to cope with big plans constantly changing; solutions that seem to have unacceptable compromises (e.g., bean counters say ‘no’); trying to run business as usual in the middle of a huge building site; all whilst introducing new stock and retiring and/ or cascading legacy stock. There will be a backdrop of conflicting requirements hour by hour, and uncertainty for many people such as TUPE, role changes, and possibly voluntary severance. And safety is only maintained by sticking to core principles.

Finally in this section, Mark Knowles, leading on train maintenance/depot/stabling strategy for the Great British Railways Transition Team, outlined the emerging strategy for the sector. The current proposal assumes ‘targeted’ electrification roll out and decarbonisation objectives. The strategy is aimed at meeting the maintenance needs of a very rapidly developing mix and deployment of fleet traction types: electric, battery, diesel, bi mode, and hydrogen.

» ‘Principal depots’ will be a centre of excellence for rolling stock traction type.

» Existing commercial agreements would be re cast to align objectives/interests.

» There will be a template commercial model for new and cascaded stock to align interests.

» Stabling locations will be selectively developed to improve capability.

» The operator’s role as ‘maintenance controller’ will be enhanced with improved data, analysis, and knowledge.

» Operational excellence model will be developed and deployed throughout.

Mark said that deployment of this strategy will create better control for the operator, improve standards, create required flexibility, provide for growth, reduce operational costs, and equip maintenance operations for the future. He identified four ‘pillars’ that would be used to enable change:

Pillar 1 is intended to help locate depots in the right place. Mark highlighted a depot and stabling facilities case study and said that once the train plan/ timetable is determined, the purpose of Pillar 1 is to define the future roles for depots and align capacity and capability for forecast needs (including growth) driven by electrification and decarbonisation objectives and traction solutions. This strategy also proposes an enhanced role for stabling locations reducing demand for further depot development, improving service delivery, and reducing ECS costs.

The purpose of Pillar 2 is to create more permissive agreements between asset owners, maintainers, and train operators which align objectives and create the environment for flexibility, innovation, and change which will be required in the future railway.

The purpose of Pillar 3 is to make full use of available data regarding train performance and faults to inform intelligent planning, deliver timely interventions, and avoid over maintaining rolling stock fleets in order to optimise reliability at lower cost.

Finally, the purpose of Pillar 4 is to make rolling stock maintenance and service delivery a fully planned, resourced, and expertly delivered activity using best practice.

Mark concluded with expected benefits including efficient, cost-effective maintenance delivery; stable, highly trained and capable maintenance teams; lower industry costs per vehicle mile; fewer empty stock movements; greater flexibility/agility to deal with changes resulting

from decarbonisation and electrification; and reduced need for depot development/ extension in response to increased demand. His final remark was that there would be opportunities for private the sector.

This seminar and a subsequent new and cascaded fleet event were intended to provide lessons learned for others’ benefit and to publicise good practice guidance now available. A takeaway was that the message had certainly landed with the Great British Railways Transition Team which is working hard to deliver a strategy that will avoid the challenges caused to depots by the recent major programme of new and cascaded vehicles.

- Depot Protection Systems (DPS)

- Depot Control Systems (DCS)

- Combined DPS/DCS

- Locally Operated Points Systems (LOPS)

- SIL 2 Rated Systems as Standard

+44 (0)1621 743 743

info@ rstclass-safety-control.co.uk www.FirstClass-Safety-Control.co.uk

At the Rail Partners ‘Train Depots for Today and Tomorrow’ event, Matt Spence, who was speaking on behalf of Dr Stuart Smith, Ergonomics & Human Factors Lead at HS2, talked about the concept for the forthcoming HS2 depot partly on the site of the former Metro-Cammell factory at Washwood Heath in Birmingham. It will be the operational base and maintenance hub for the HS2 fleet and will also be the location of the HS2 Network Integrated Control Centre (NICC).

A huge site, it will be a 24/7/365 depot with most activity at night. At the Birmingham end there will be 16 stabling roads each capable of accommodating 400-metre-long trains (one unit or two, 200-metre units coupled). It is planned that trains will be driven between the main line and the sidings in ATO mode. At this end of the depot, train cleaning and servicing activities will take place and there will be a building with train simulators and other facilities for the circa 200 drivers, and cleaning and servicing staff.