Harman interview P38 Fashion details P30 TECHNOLOGY FOR THE PRODUCT LIFECYCLE DECEMBER 2022 / JANUARY 2023 | £6 | € 7 | $10 | DEVELOP3D.COM ROBOT INSPECTORS NEXT-GEN PIANO DESIGN THE NEED FOR BIOPOLYMERS

UP! Wearables design for working life from RealWear Inside Makelab P34 FREE INSIDE WORKSTATION SPECIAL REPORT

HEADS

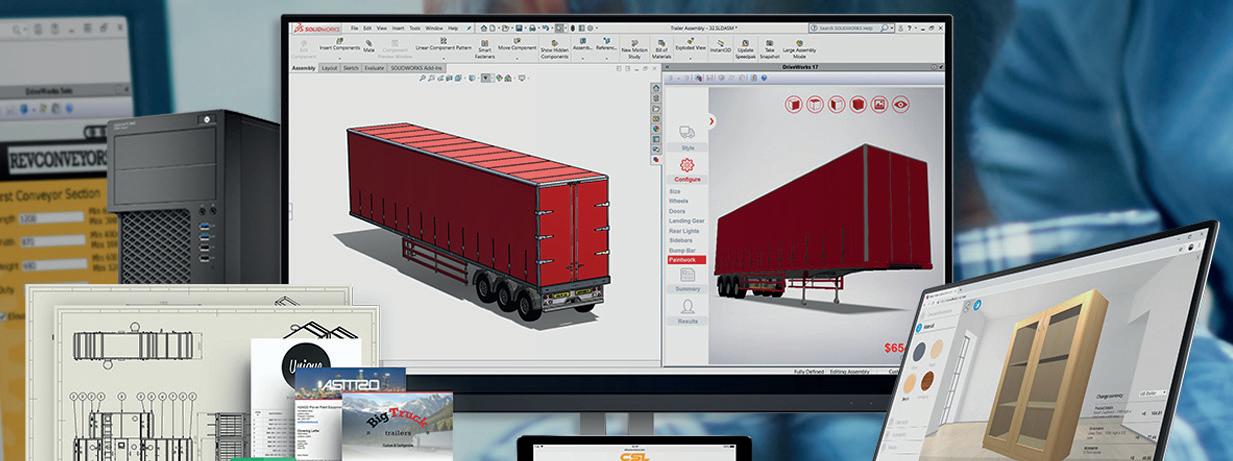

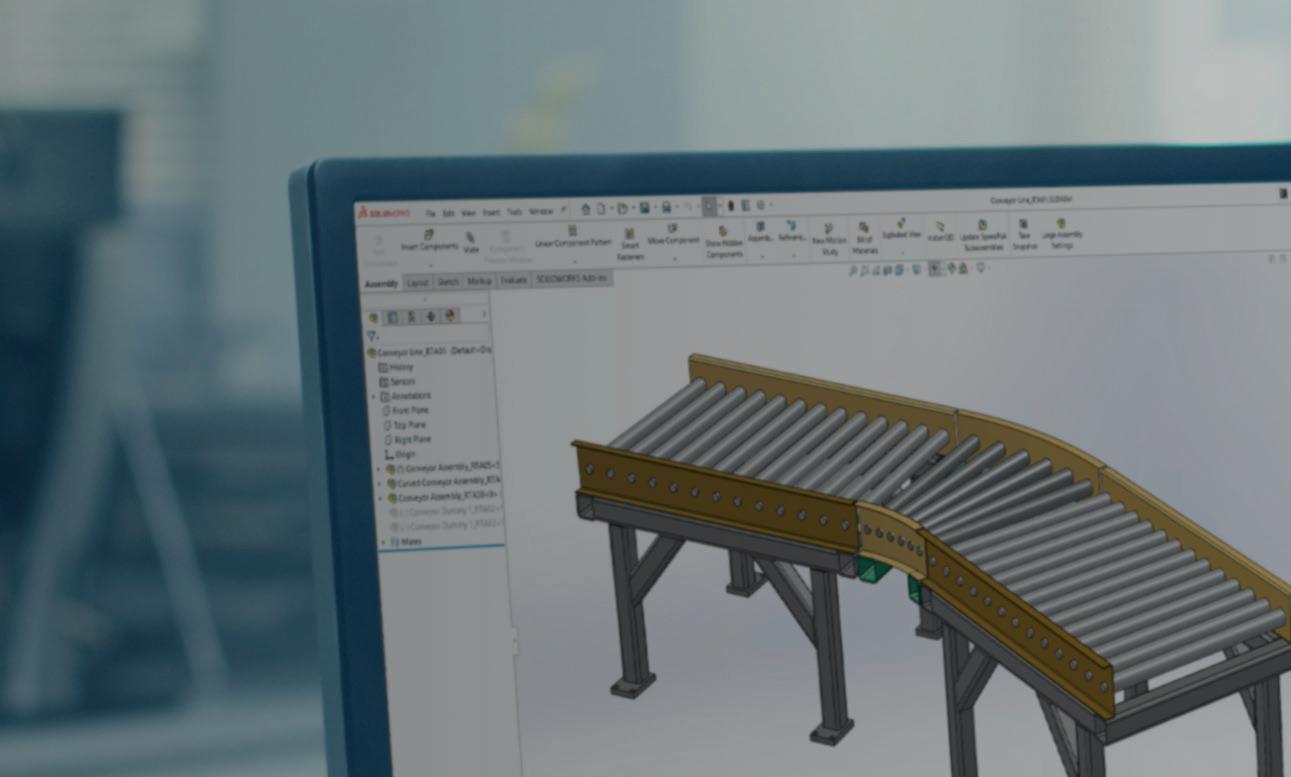

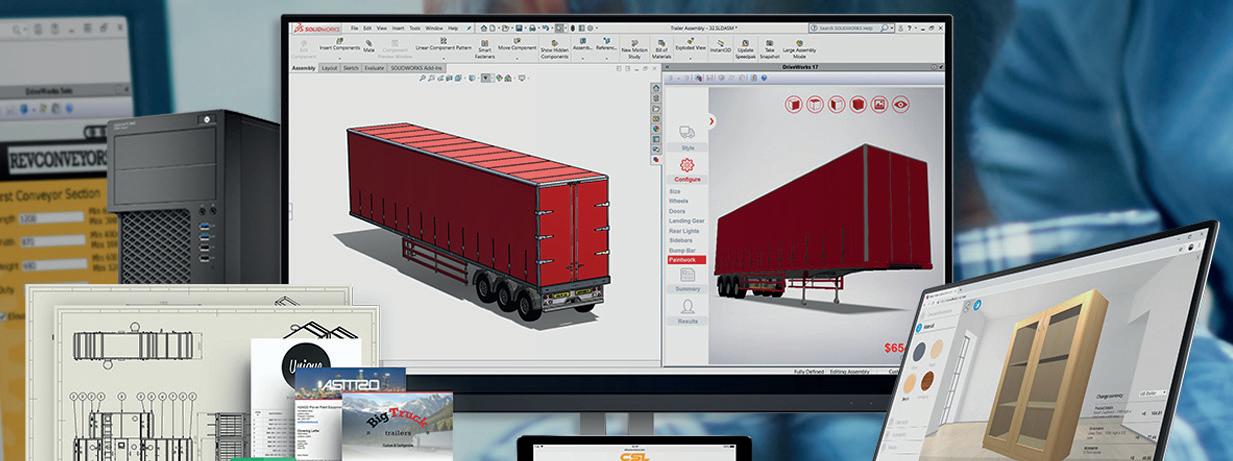

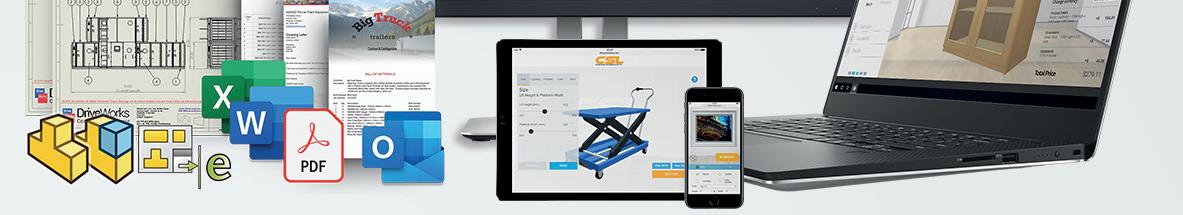

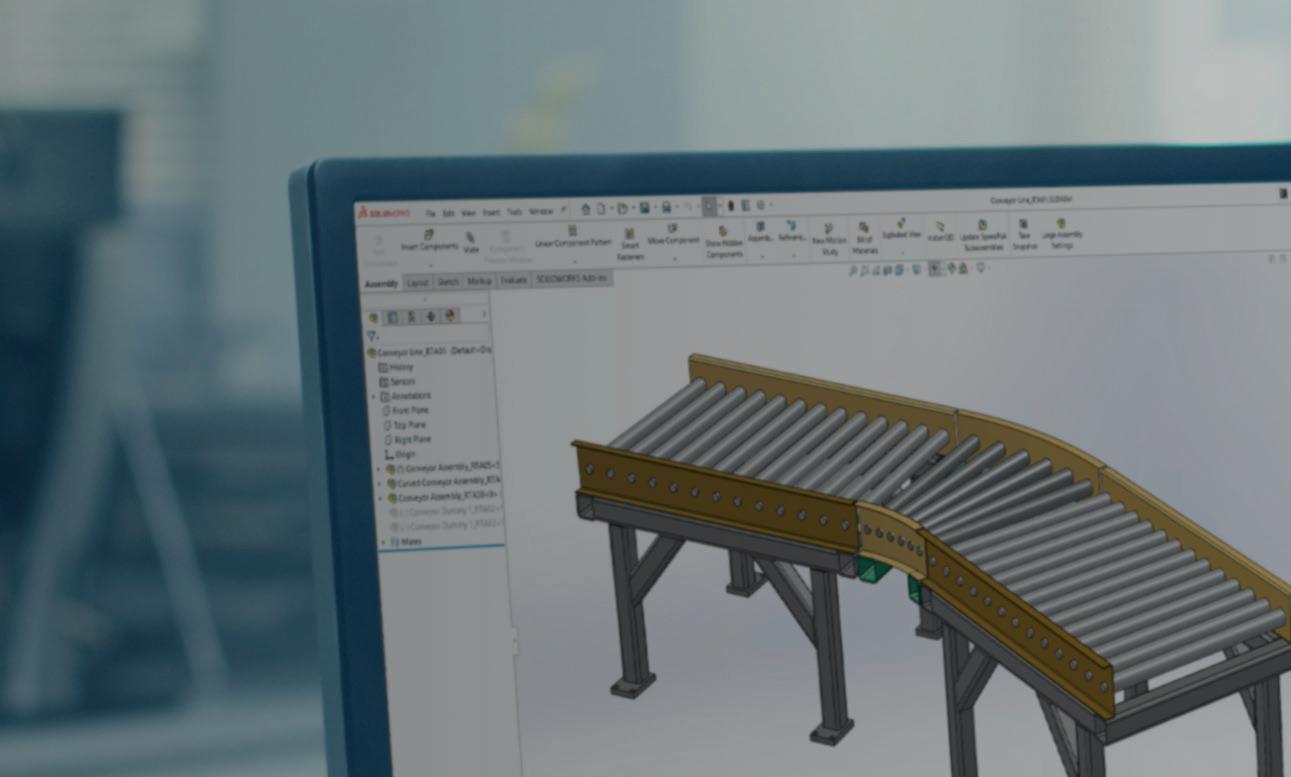

Automate SOLIDWORKS manufacturing processes & sell digitally using DriveWorks

DriveWorks is flexible and scalable. Start for free, upgrade anytime. DriveWorksXpress is included free inside SOLIDWORKS or start your free 30 day trial of DriveWorks Solo.

30DAY

Automate

assemblies and drawings Generate production ready drawings, BOMs & quote documents automatically Enter product specifications and preview designs inside SOLIDWORKS Free online technical learning resources, sample projects and help file

Modular SOLIDWORKS® automation & online product configurator software

Complete SOLIDWORKS part, assembly and drawing automation

Automatically generate manufacturing and sales documents

Configure order specific designs in a browser on desktop, mobile or tablet

Show configurable design details with interactive 3D previews

Integrate with SOLIDWORKS PDM, CRM, ERP, CAM and other company systems

Scalable and flexible licensing options

One time setup

Set up once and run again and again. No need for complex SOLIDWORKS macros, design tables or configurations.

Save time & innovate more Automate repetitive SOLIDWORKS tasks and free up engineers to focus on product innovation and development.

Eliminate errors

DriveWorks rules based SOLIDWORKS automation eliminates errors and expensive, time-consuming design changes.

Connect sales & manufacturing

Validation ensures you only offer products that can be manufactured, eliminating errors and boosting quality.

Integrate with other systems

DriveWorks Pro can integrate with other company systems, helping you work more efficiently and effectively.

Intelligent guided selling

Ensure your sales teams / dealers configure the ideal solution every time with intelligent rules-based guided selling.

Find under the SOLIDWORKS tools menu Entry level SOLIDWORKS part

Create a drawing for each part and

SOLIDWORKS®

Sold and supported by your local SOLIDWORKS reseller

DriveWorksXpress Entry level design automation software included free inside SOLIDWORKS®

and assembly automation

assembly DriveWorks Solo

part, assembly and drawing automation add-in

SOLIDWORKS parts,

FREETRIAL

DriveWorks Pro

and supported by your local SOLIDWORKS reseller

Sold

www.driveworks.co.uk Try examples online at www.driveworkslive.com

EDITORIAL Editor Stephen Holmes stephen@x3dmedia.com

+44 (0)20 3384 5297

Managing Editor Greg Corke greg@x3dmedia.com

+44 (0)20 3355 7312

Staff Writer Claudia Schergna claudia@x3dmedia.com

Consulting Editor Jessica Twentyman jtwentyman@gmail.com

Consulting Editor Martyn Day martyn@x3dmedia.com

+44 (0)7525 701 542

DESIGN/PRODUCTION

Design/Production Greg Corke greg@x3dmedia.com

+44 (0)20 3355 7312

ADVERTISING

Group Media Director Tony Baksh tony@x3dmedia.com

+44 (0)20 3355 7313

Deputy Advertising Manager Steve King steve@x3dmedia.com

+44 (0)20 3355 7314

US Sales Director Denise Greaves denise@x3dmedia.com

+1 857 400 7713

SUBSCRIPTIONS

Circulation Manager

Alan Cleveland alan@x3dmedia.com

+44 (0)20 3355 7311 `

ACCOUNTS

Accounts Manager Charlotte Taibi charlotte@x3dmedia.com

Financial Controller

Samantha Todescato-Rutland sam@chalfen.com

Wrapping up the final issue of DEVELOP3D for another year, I’ve had time to reflect on all the people, topics and products we’ve looked at in these pages during 2022. We’ve covered a lot of ground, and we’ll be aiming to give you just as much variety in 2023.

This issue is no exception. Greg has been beavering away to produce an exceptional Workstation Special Report, full of insight and reviews of the latest in hardware, processing and graphics.

Our cover story looks at a different type of hardware, as the wearable technology experts at RealWear give us a peek behind the curtain at their company. These headsets are built specifically for industrial use, eschewing flimsy futuristic consumer tech for tried-and-tested resilience and proven ergonomics. Meanwhile, Claudia conducted not one, but two excellent interviews for this issue. One was with Harman’s Philipp Siebourg, with the future of car audio design under the spotlight. The other was with Christina Perla, CEO and co-founder of MakeLab, a woman working to make additive manufacturing more accessible to a far wider range of creatives and companies.

Elsewhere, we also tinkle the ivories with Casio, as its Tokyo design team talks us through the process of creating a piano designed to fit modern lives and living spaces.

I’ll sign off here with a huge thanks to everyone who has contributed to DEVELOP3D over the past 12 month, giving us their time, helping us to pull together these pages, offering their opinions, or simply getting in touch for a natter.

In 2023, DEVELOP3D celebrates its 15th year in print and we look forward to celebrating that milestone with all our readers!

Stephen Holmes Editor, DEVELOP3D

@swearstoomuch

DEVELOP3D.COM DECEMBER 2022 / JANUARY 2023 3

ABOUT DEVELOP3D is published by 19 Leyden Street London E1 7LE, UK T. +44 (0)20 3355 7310 F. +44 (0)20 3355 7319 © 2022 X3DMedia Ltd All rights reserved. Reproduction in whole or part without prior permission from the publisher is prohibited. All trademarks acknowledged Opinions expressed in articles are those of the author and not of X3DMedia. X3DMedia cannot accept responsibility for errors in articles or advertisements within the magazine

WELCOME DEVELOP3D.com facebook.com/DEVELOP3D @DEVELOP3D groups/DEVELOP3D Join our online community

Magazine,

The Tools to Supercharge Your CAD Workflow

SpaceMouse ®

Smooth, intuitive and powerful navigation

CadMouse

Specially designed for CAD professionals

Keyboard Pro with Numpad

Customization taken to the next level

out more

Find

NEWS

PTC buys ServiceMax in a bid to stretch the digital thread, Epic Games adopts Hoops Exchange for CAD import and Siemens launches Simcenter Cloud HPC

FEATURES

Comment: IDC’s Luke Williams on biopolymer futures

Comment: SJ on manufacturing workforce mathematics

Visual Design Guide: Toka 4 from Gecko Robotics

COVER STORY Workplace wearables get real Sweet music: Casio rethinks the piano for modern homes

Eurominuterie’s stylish designs for garment details

Inside Makelab: A new breed of copy shop

Q&A: Philipp Siebourg of Harman International

THE LAST WORD

The way we purchase many products is changing, creating challenges for designers and manufacturers. How might these shifts impact our gift-giving habits? FREE

Comment: workstation energy efficiency

13th Gen Intel Core vs AMD Ryzen 7000 CPUs

Review: Scan desktop workstations

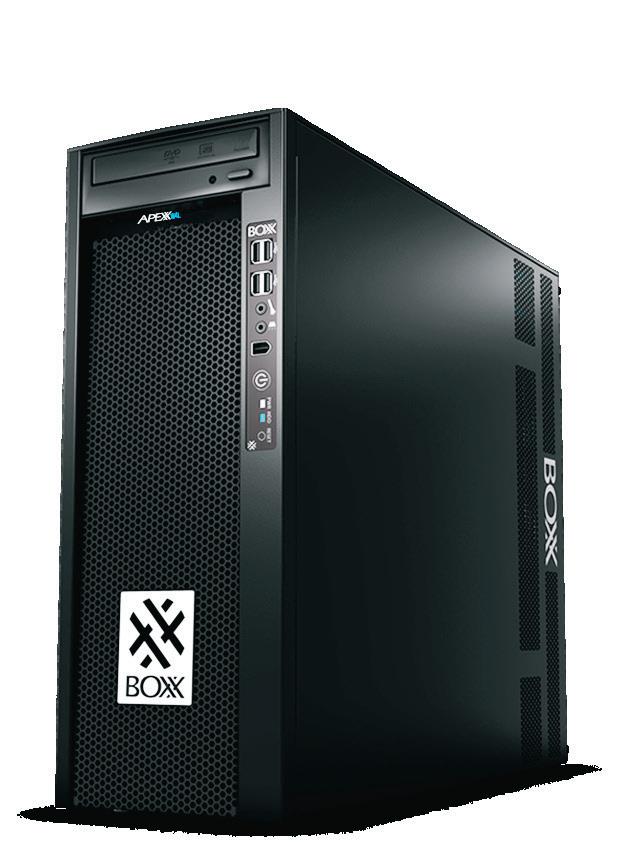

Review: Boxx Apexx S4.04 workstation

Review: HP Z2 Mini G9 workstation

Round-up: mini desktop workstations

Review: Armari Magnetar M64TP-RW1300G3

Review: Dell Precision 5470 mobile workstation

Round-up: ultra-portable mobile workstations

Review: Intel Arc Pro A40/A50 GPUs

Review: Nvidia RTX A2000 / Nvidia T1000 GPUs

AMD Radeon Pro OpenGL driver

DEVELOP3D.COM DECEMBER 2022 / JANUARY 2023 5

INSIDE WORKSTATION SPECIAL REPORT

DECEMBER 2022 / JANUARY 2023 ISSUE NO. 137 06 13 14 16 20 26 30 34 38 44 WS03 WS04 WS14 WS17 WS18 WS19 WS20 WS24 WS25 WS28 WS34 WS36

magazine

Forest Stewardship Council certified well-managed forests, controlled sources and/or recycled material CONTENTS www.develop3d.com December January2023 workstationspecialreport With impressive performance and hardware tracing built this low profile graphics card transform theworkflows lovers smalldesktop workstations,writesGregCorke SmallFormFactor(SFF)worksta like Precision 3460 havebecomeextreme ly popular designers and engineers because they take up signifi cantly spacethanstandarddesktop towers. However, because their slenform,theyhavebeenlimitedtoprofile’GPUs halfheightbracket. Historically,low-profilecardshavebeen verymuch‘entry-level’—perfectlygood for CAD, lacking performance featuresformoredemandingworkflows asreal-timevisualisationand raytracerendering. This changed last with introduction Nvidia RTX A2000. This powerful low GPU not only delivered more performance than before, but introduced RTX technologyentry-levelsegment.Previously, order professionalNvidiagraphics with hardware ray tracing built-in, you needed classGPU. The other major difference between theNvidia A2000andprevious low-profile offerings that double height board, taking up two on motherboard.accommodate beefier type for better cooling, where hot directly exhausted the workstation via the on bracket. size, Nvidia RTX A2000 started workstations well, as the Z2 MiniG9(seepage18). But not limited to workstations. can fitted standard towers, when GPU purchasedseparately comeswith half heightandfullheightATXbracket. Nvidia A2000 featured GBofGDDR6memory. timeoflaunch we suggested might be light its intended workflows. After all, datasets quickly swell, especially 4K resolution. recently,however,Nvidia released GB version, which subject thisreview. GB models identical with Mini DisplayPort outputs and minimal matt black enclosure. maxboard of70W GPU designed to operatewith slot the A2000 with full suite proapplications. In and software Inventor, Solidworks Revit — thandelivered.Compared to the Nvidia A4000, SPECapc Solidworks benchmark scores may dropped off 4K resolution, we still perfectly smooth viewport with 26.4 Frames Second (FPS) testing our large 2,300 part, milliontrianglesnowbikeassemblywith vizworkflowsthingsstartedto down little. While card showed great performance FHD resolution, dropped considerably especially in some of our more demanding tests. VRED Professional 2023 with aliasing to ultra-high in Unreal Engine 4.26 ray tracing enabled, reacheddoubledigits.InGPUrendering,the A4000was 88% faster V-Ray, in Solidworks Visualize stillrendered Camaro model 4K(100passes de-noising) in perfectlyacceptable38.5seconds. an ourtestinghighlightedimportanceofselecting rightprodriver. Newerisnotalwaysbetter.InSolidworks Visualize 2022, card almost timesslower the driverthan with certified516.94 verdict its impressive performance hardware ray tracing, Nvidia RTX A2000 has completely transformed the andultra-compactworkstation.excellentchoice CADusers want to expand design visualisation, with dedicated tools KeyShot GPU tracersthatarestarting make way CADviewports. forgetabout GBversion card. much better now well the TheRTXA2000 notthe for you designvizseriously.TheRTXandabove much suited moredemandingworkflows,especially resolution. these full boardsforfull sizedtowers. youhaveyourheart pint-sizeddesktop,thenthere’snothing outthererightnow comesclose. NvidiaRTX RTXA2000(12GB) budgets and little designvisualisation, should Thislow-profile nailed CAD.DisplayPorts, max models. Solidworks2022, our assemblies, hardly difference Nvidia A2000. And (Ex cheaper. Nvidia T1000 (8GB) RTX opens possibilities entry-level viz workstations applications KeyShot courtesy Cooper) WS34_D3D_DEC22FEB23_Nvidia-RTX-A2000.indd 19/12/2022 www.develop3d.com workstationspecialreport Threemoreultra-compactdesktopworkstationsforspace-constrained environments,orsimply sitprettyonyourdesk Tinydesktopworkstationsthealternatives 190 178mm, microworkstation smaller the G9, narrows your 65W Intel shouldn’t you CAD difference performancebetween 65W i9-12900 i9-12900K neglible, you’ll get multi-threadedperformance rendering. There’s compromise graphics GPUs Nvidia A2000 covering viz. machine from choice storage HDDs SSDs) are ports can VESA-mounted Dell’s all-in-onemonitor (pictured) deskclutter-free. Precision3260 name, nature, ThinkStation workstation 183mm. just this is, ports picture left. thermals check, presume ThinkStation can low processors, configured or Gen CPUs (up plus pro the T1000 making for machine placed desktop mode the stand) under or VESA with custommounting and kg) can throw between and lenovo.com/workstations LenovoThinkStationP360Tiny powerful option high-performanceGPU opens Nvidia A5000 GB) well real-time and tracing.However, expect exact level performance would standard mobile desktop draws less ThinkStation 202mm features design themotherboard the andserviceability. the supports 128 DDR5 memory, smaller Precision Compact, 12th processors lenovo.com/workstations ThinkStationP360Ultra www.tinyurl.com/P360-ultra WS19 December2022 January workstationspecialreport Vs WS04_05_06_07_08_09_10_D3D_DEC22JAN23_Intel_AMD.indd 19/12/2022 WorkstationspecialreportforCAD,visualisationandbeyond DECEMBER 2023 DEVELOP3D.COM THEBATTLEOFTHECPU 13thGENINTELCOREVERSUS CAD-CENTRICAMDRYZEN7000FORWORKFLOWS MINIWORKSTATIONS POWERFUL MACHINES TO SIT PRETTY ON YOUR DESK OR HIDE BEHIND A DISPLAY INTELARCPRO WHAT DO INTEL’S LONG AWAITED DISCRETE GPU MEAN FOR CAD AND VIZ? Vs Slimline laptops PORTABLE MOBILE WORKSTATIONS Exclusive WS01_D3D_DEC22JAN23_Cover.indd 19/12/2022 PLUS

The wood used to produce this

comes from

PTC ANNOUNCES ACQUISITION OF SERVICEMAX IN A BID TO STRETCH THE DIGITAL THREAD

PTC has announced the acquisition of ServiceMax, in a move designed to strengthen its closedloop product lifecycle management (PLM) offerings.

ServiceMax, a provider of cloud-based field service management (FSM) software, is expected to be fully integrated into PTC by the end of January 2023.

The acquisition was signed for almost $1.5 billion and aims to expand PTC ’s offerings by extending the digital thread of product information into downstream enterprise asset management and FSM capabilities.

This deal is particularly strategic for PTC, executives from the company said, because its manufacturing customers rely on FSM for product performance, customer satisfaction and profitability. “The addition of ServiceMax will realise a key part of PTC ’s closed-loop PLM strategy,” said PTC president and CEO Jim Heppelmann.

As he explained, the PLM capabilities that PTC already offers engineering and manufacturing firms provide a system of record for the digital definition of any product configuration. ServiceMax adds to this, by providing a system of record for monitoring and servicing products after they leave the factory and are in use by customers.

ServiceMax has changed hands regularly in recent years. PTC is acquiring the company from the private equity firm Silver Lake, which in turn purchased it from General Electric in 2018.

The ServiceMax FSM platform is typically used by companies with extensive field service and support operations, helping them to coordinate out equipment repairs.

For instance, a wireless network operator might use the platform to dispatch technicians to a mast or radio base station experiencing technical issues.

Additionally, ServiceMax provides a mobile app, giving engineers working in the field immediate access to technical data on how to repair malfunctioning equipment and information on the availability of spare parts needed to make a fix, among other functions.

“Upon completion of this acquisition, PTC will have the unique ability to complement the full digital product definition from our computer-aided design (CAD) and PLM solutions with detailed usage information from our Internet of Things (IoT) solutions and the complete service history from ServiceMax,” said Heppelmann.

In that respect, he claimed, PTC “is poised to be the only company that will be able to offer manufacturers this comprehensive view of their products at each stage of the lifecycle.”

ServiceMax and PTC have worked together since 2015 to support manufacturers in the creation of complex, highly configured products for the medical, industrial and aerospace industries.

The two companies said FSM is key for manufacturers in those industries, as it allows them to maintain product performance, extend product lifecycles, increase customer satisfaction, drive revenue growth, and expand profitability.

“ServiceMax and PTC have a longstanding relationship rooted in the common profile of our customers, the natural synergies of our products, and a shared understanding of the importance of product data at different stages of the lifecycle,” said ServiceMax CEO Neil Barua. ServiceMax was built on the Salesforce platform and offers capabilities that include management of all relevant information about serviced products, creation/management of work orders, and scheduling/dispatching of technicians. These capabilities integrate closely with Salesforce’s customer relationship management (CRM) capabilities.

Alongside its FSM platform, ServiceMax also offers an artificial intelligence tool, which can recommend possible ways to fix a malfunction and rank answers by their likelihood of success. www.ptc.com

Field service engineers use ServiceMax to access information on appointments, consult technical information and check on spare parts

6 DECEMBER 2022 / JANUARY 2023 DEVELOP3D.COM NEWS

NEWS

» The cloud-based field service management provider brings PTC users a system of record for products after they have left the factory and are in use by customers

Intel® Arc™ Pro A40 GPU unites fluid viewports, the latest in visual technologies, and rich content creation in a condensed half height, half length form factor. • Ray Tracing Hardware Acceleration • Dedicated AI Acceleration • Industry First AV1 Hardware Encode • 6GB High Speed Memory • Software Certifications • Up to 4x Displays, with Audio Support and Latching Mechanism • Single Slot, Tiny Form Factor • Premium Components • Extended Warranty Professional Graphics Begins Here Intel.com/ArcProA40 © Copyright 2022 Intel Corporation. All rights reserved. Intel, the Intel logo, and other Intel marks are trademarks of Intel Corporation or its subsidiaries. Intel Arc Graphics is a trademark of Intel Corporation in the U.S. and/or other countries. Other names and brands may be claimed as the property of others.

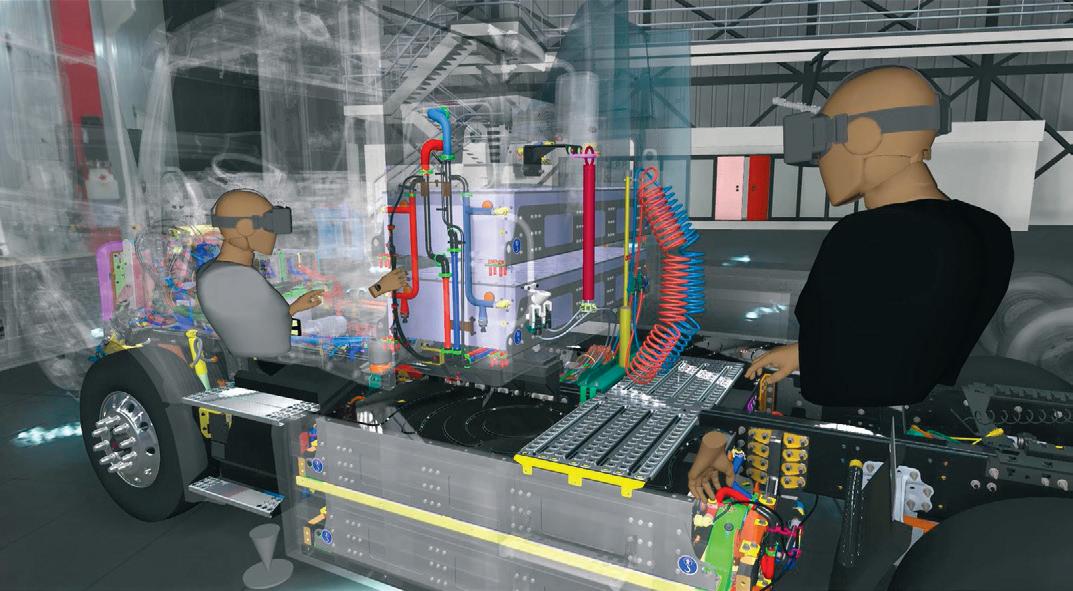

EPIC GAMES ADOPTS HOOPS EXCHANGE FOR CAD IMPORT

Stratasys buys QA expert Riven

Stratasys has acquired Riven, a cloud-based quality assurance software that aims to help customers inspect, diagnose and correct deviations between CAD files and 3D-printed parts, resulting in higher accuracy rates and lower costs.

Riven’s technology will be integrated into Stratasys’ GrabCAD Additive Manufacturing Platform, benefiting customers that use a Stratasys 3D printer running GrabCAD Print software. A new version of this software that uses artificial intelligence to pre-adjust models automatically is currently being tested, according to Stratasys execs.

www.stratasys.com

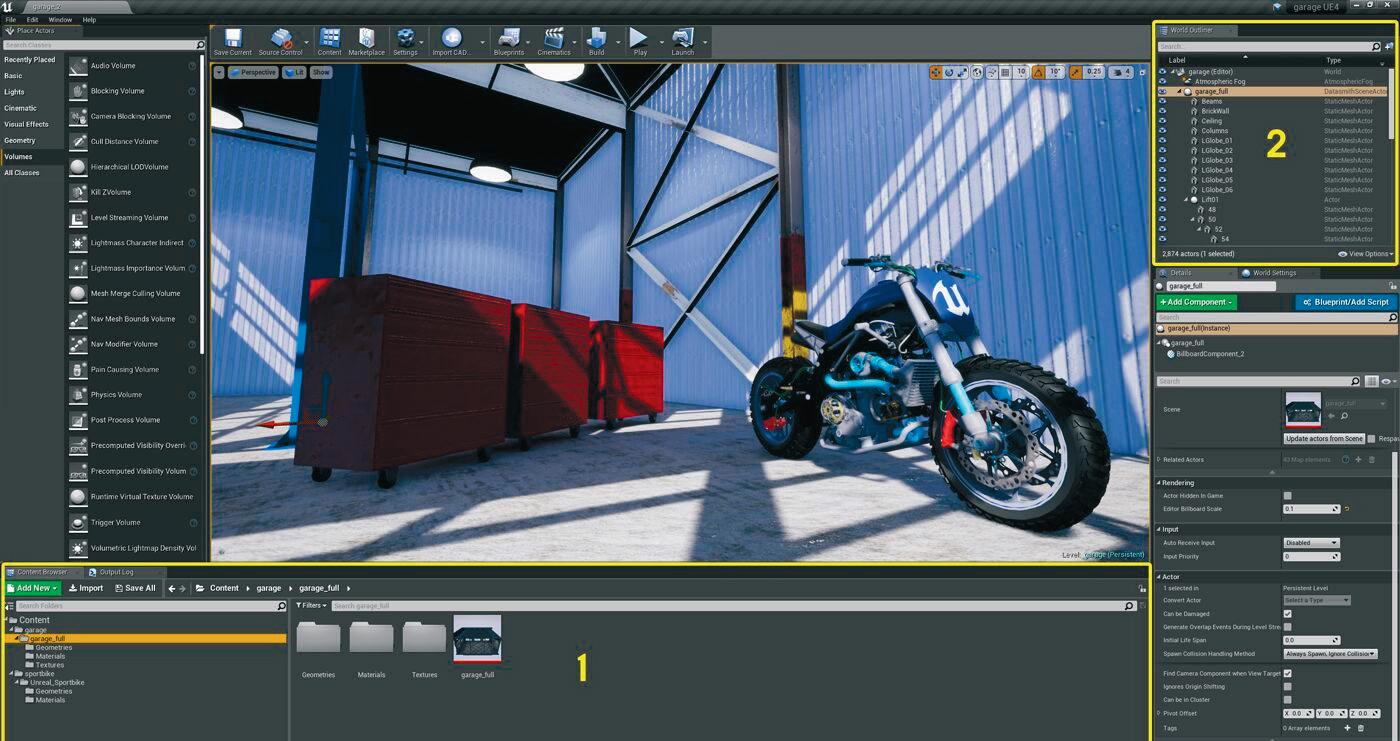

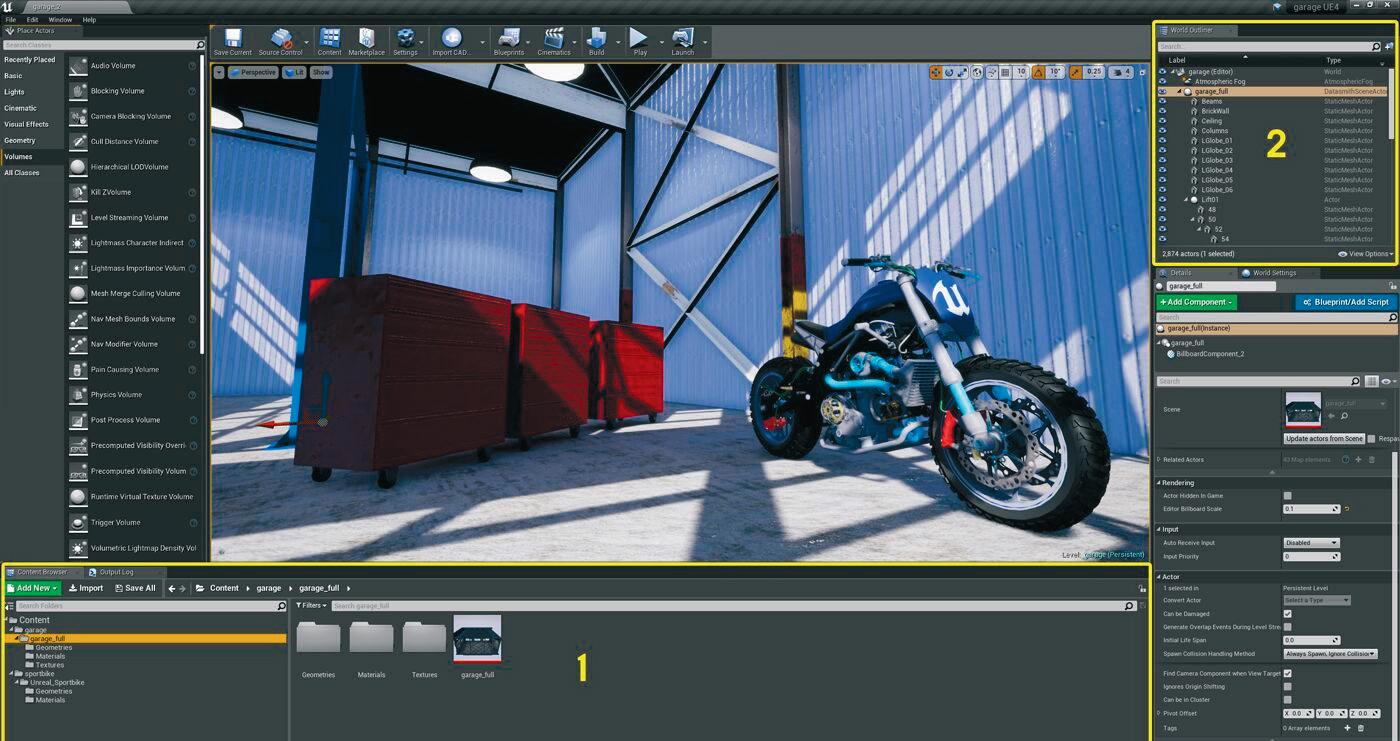

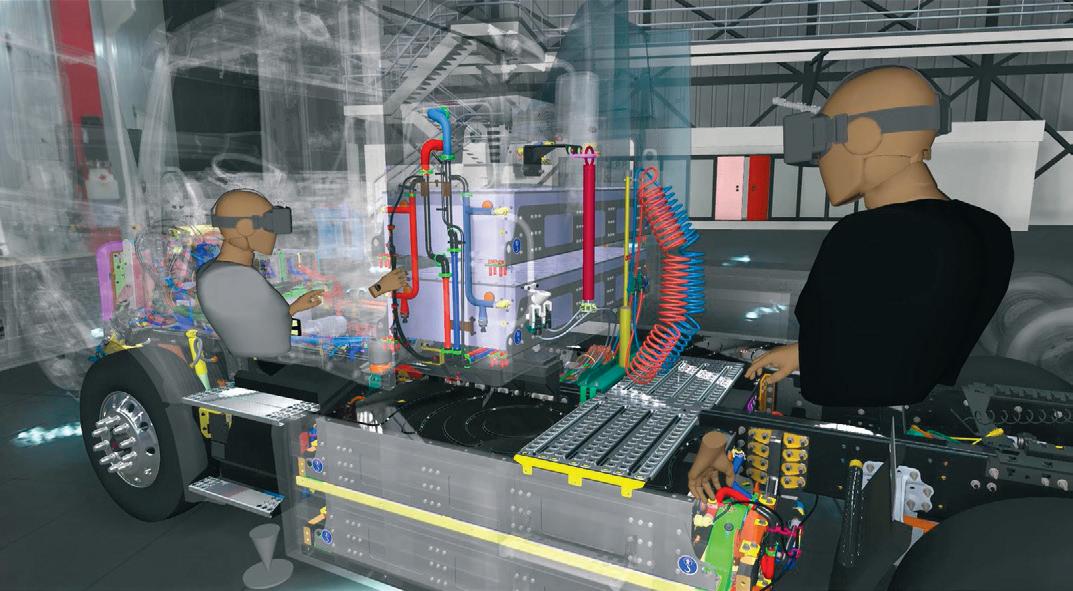

Epic Games has announced it has selected Hoops Exchange from Tech Soft 3D to simplify CAD data import. The technology will be incorporated into Epic's Datasmith pipeline, used to bring CAD models into the Unreal game engine to create more sophisticated visualisation and interactive applications.

According to Epic Games, customers from industries including automotive and aerospace had previously complained that they found it challenging to get their data into Unreal Engine, because CAD data is typically created for manufacturing, rather than for interactive visualisation.

To solve this problem, Epic Games built Datasmith, a collection of tools that allows Unreal Engine customers to import preconstructed scenes or complex assets and

assemblies from industry-standard design applications into Unreal Engine. The result is a more streamlined workflow when it comes to importing and preparing CAD data for visualisation.

At the same time, Epic aims to support the widest possible range of 3D design applications and file formats, which is where Hoops Exchange comes into the picture. This is a software development kit, or SDK, which supports imports in over 30 CAD formats, including Catia, Solidworks, Inventor and Revit.

Epic Games has already reported positive feedback from customers. Several companies from the automotive sector, for example, have said they are now able to bring in 3D CAD models and interact with them via virtual reality, in order to perform engineering reviews.

www.epicgames.com

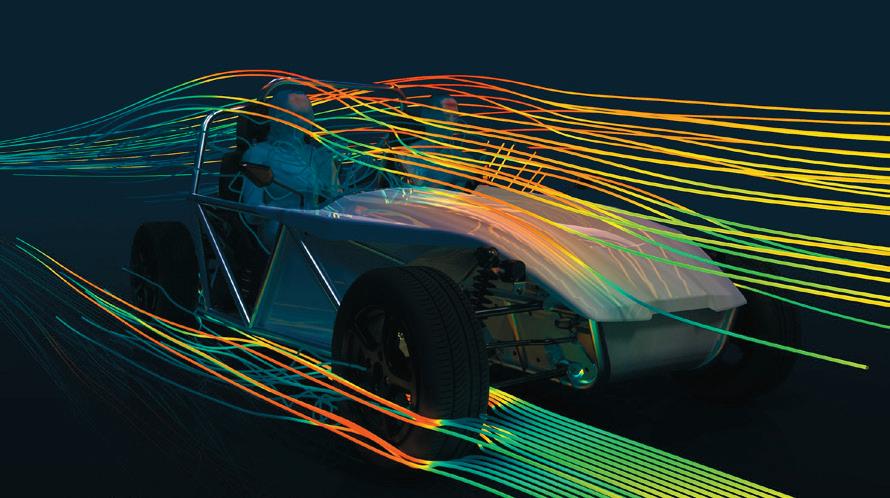

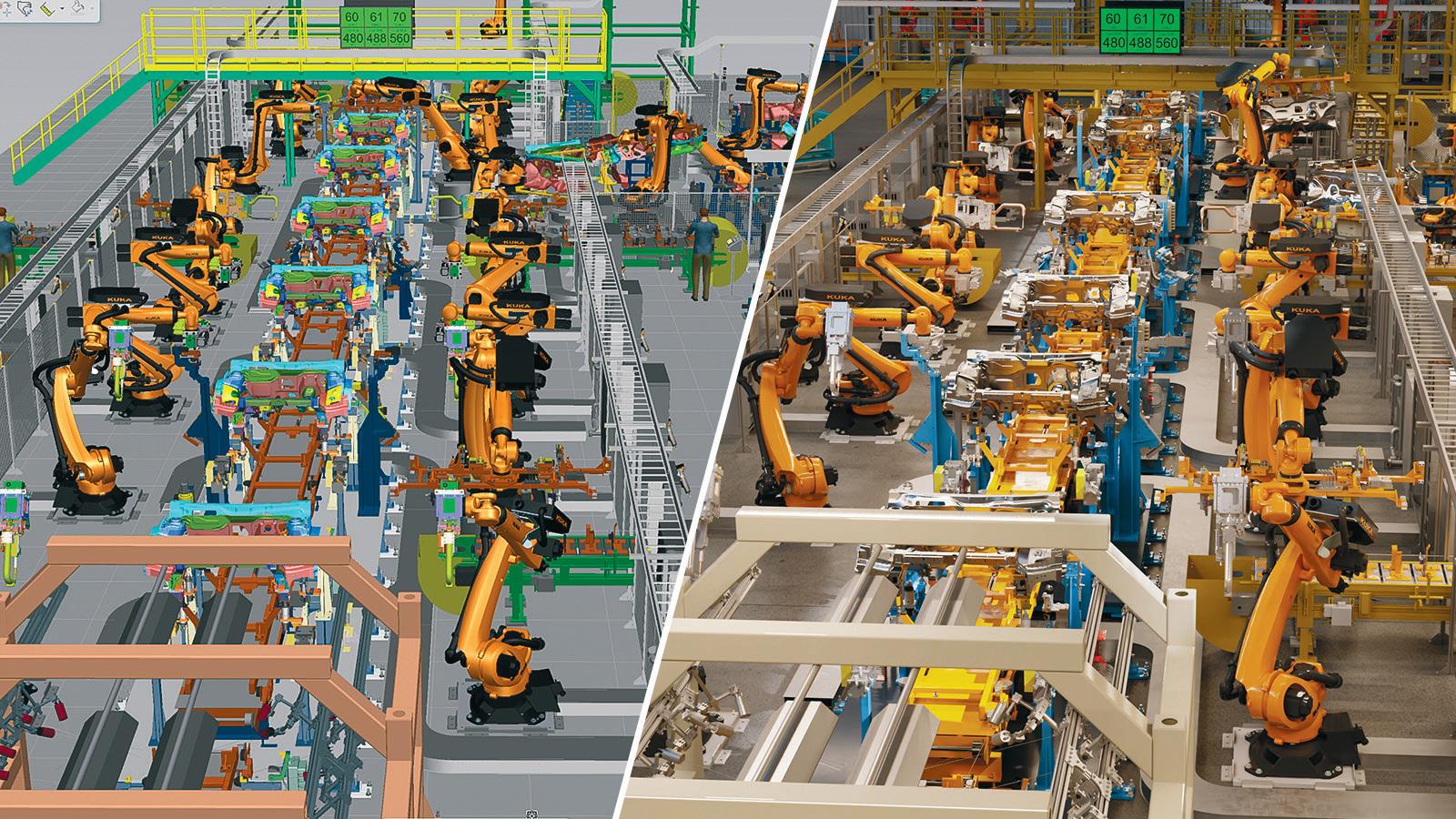

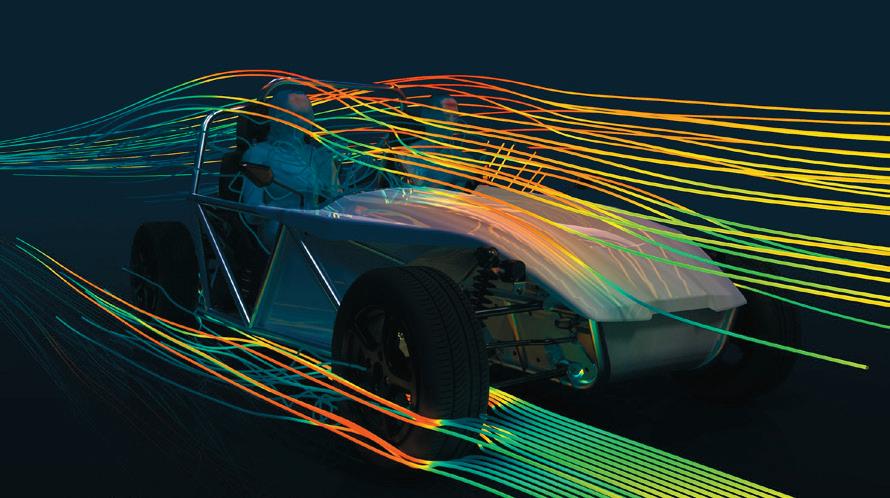

Xcelerator gains complex simulation on AWS

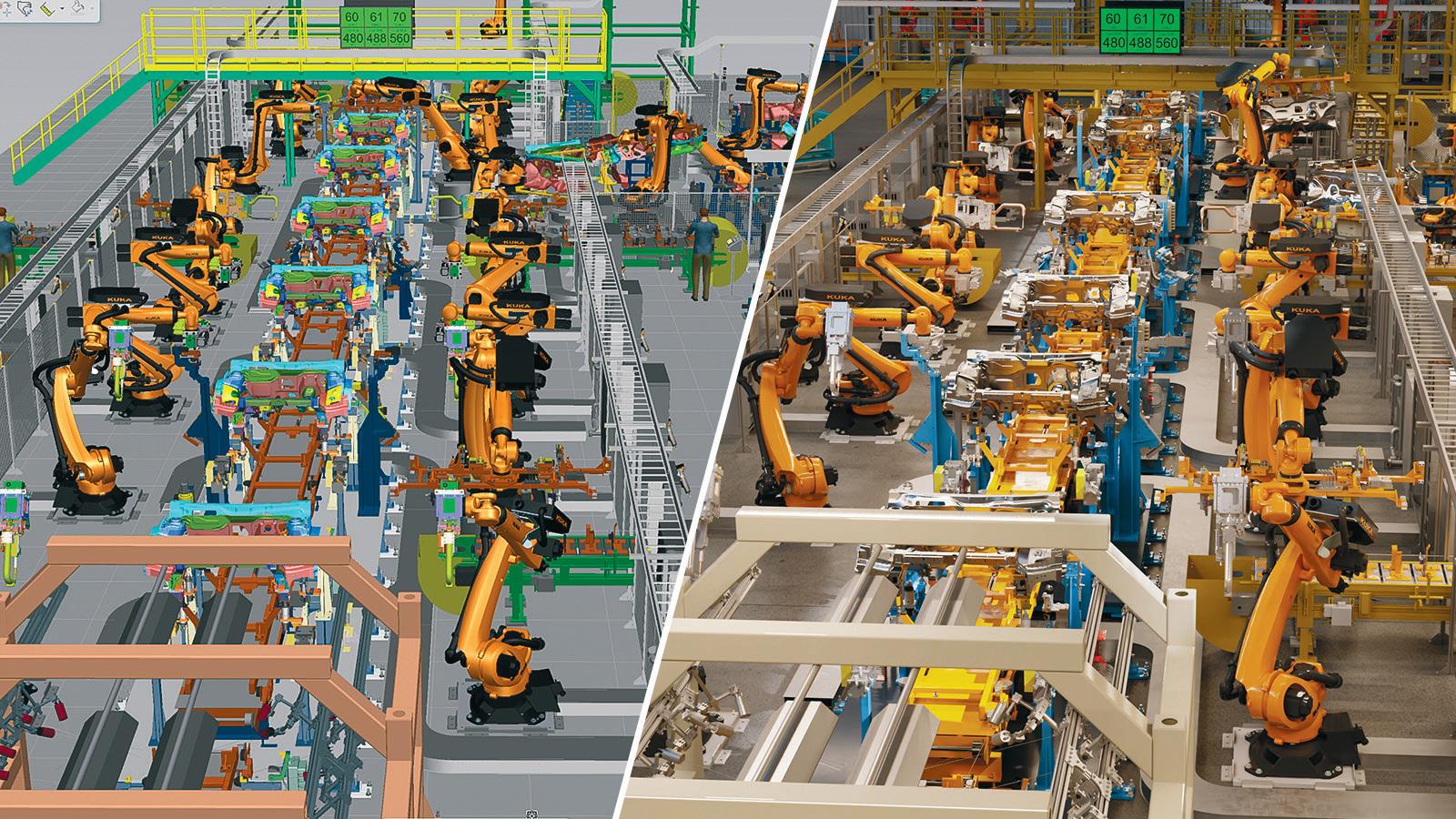

Siemens Digital Industries Software has added scalable, on-demand, highperformance simulation capabilities to Siemens Xcelerator as a Service (XaaS) with the launch of Simcenter Cloud HPC.

As part of an ongoing collaboration between Siemens and Amazon Web Services (AWS), the new service is hosted on AWS, optimised for Simcenter solver technologies and managed by Siemens.

The new service, according to Siemens executives, is designed to reduce the costs traditionally associated with onpremise high performance computing (HPC), allowing organisations of all sizes to access the benefits of advanced simulation, gain deeper insight into the performance for their products, and make more informed engineering decisions.

New LPBF app from Dyndrite

Dyndrite has announced the launch of its first enduser software, Dyndrite Materials and Process Development for LPBF.

Focused on materials and process development for laser powder bed fusion (LPBF) additive manufacturing systems, the new software takes advantage of Dyndrite’s Accelerated Computation Engine (ACE) and 3D volumetric part segmentation. Leveraging that technology, it provides the ability to work with CAD data directly, handle large files, and save and share build recipes.

www.dyndrite.com

Zortrax launches full-metal AM packages

Zortrax has launched two AM sets — Full Metal Package 17-4 PH and Full Metal Package 316L — as well as a new filament, Victrex Paek AM 200, which is designed to be extruded at lower temperatures, having a lower melting point than Peek.

Simcenter Cloud HPC is accessible seamlessly from the desktop simulation tool with no additional configuration needed, providing “immediate access to near-unlimited compute capacity”, while avoiding the cost and complexity of accessing third-party cloud services. www.sw.siemens.com

Each Zortrax Full Metal Package has been developed by the company to offer customers all the essentials for an easy start with metal 3D printing. They include either Basf Ultrafuse 316L or Basf Ultrafuse 17-4 Ph metal-polymer filaments, patented by Basf Forward AM. www.zortrax.com

8 DECEMBER 2022 / JANUARY 2023 DEVELOP3D.COM NEWS

By bringing CAD data into Unreal Engine, manufacturers can create more sophisticated visualisations

Simcenter Cloud HPC provides cloud-based capabilities for advanced simulation on AWS

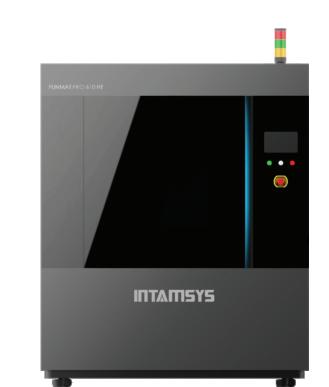

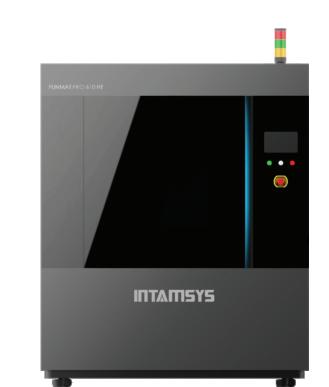

High Temp 3D Printers High Temp 3D Printers for demanding applications for demanding applications

Materials include:

PEEK, PEKK, PEI, PPSU, PC, PA, PA+CF, ABS, ASA, PETG, HIPS, TPU, PLA, PVA

610

— 260 × 260 × 260 mm

— Single head

— 450 °C extruder temp

— Print speed 300mm/s XY

— Ceramic heated bed

— 305 × 305 × 406 mm

— Dual head

— 450 °C extruder temp

— Print speed 300mm/s XY

— Ceramic heated bed

www.cdg.uk.com

— 610 × 510 × 510 mm

— Dual head

— 500 °C extruder temp

— Print speed 500mm/s XY

— Vacuum system on bed

“

Funmat HT [Enhanced]Funmat Pro 410Funmat Pro

· 01420 556755

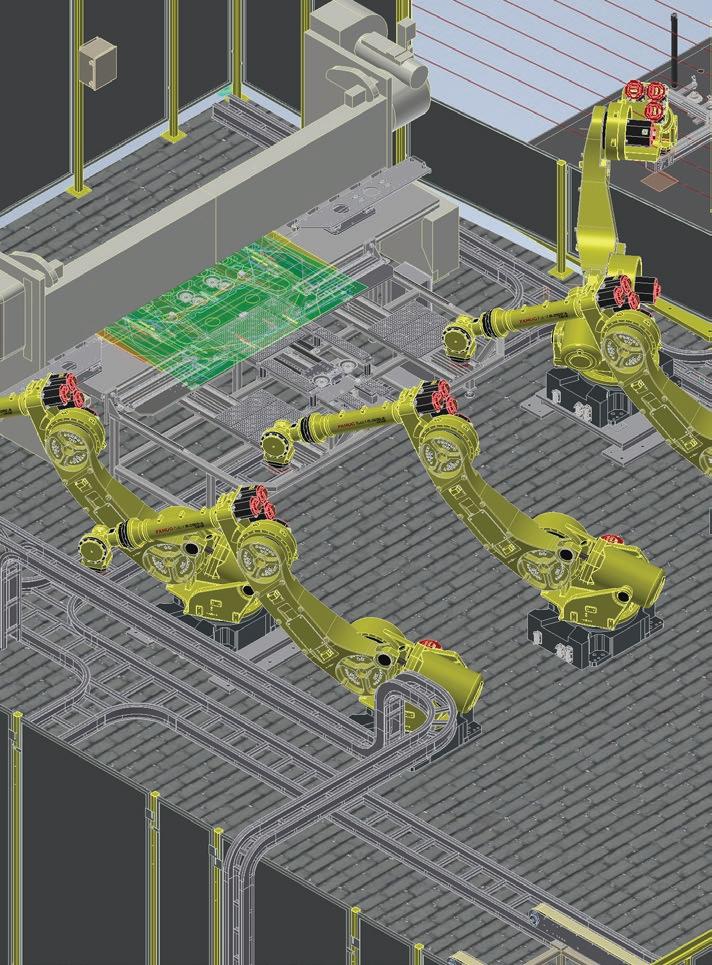

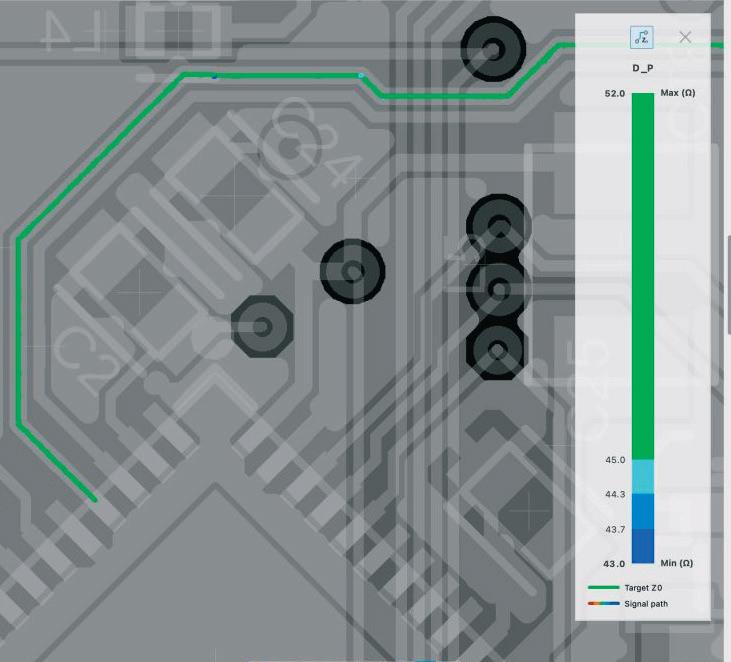

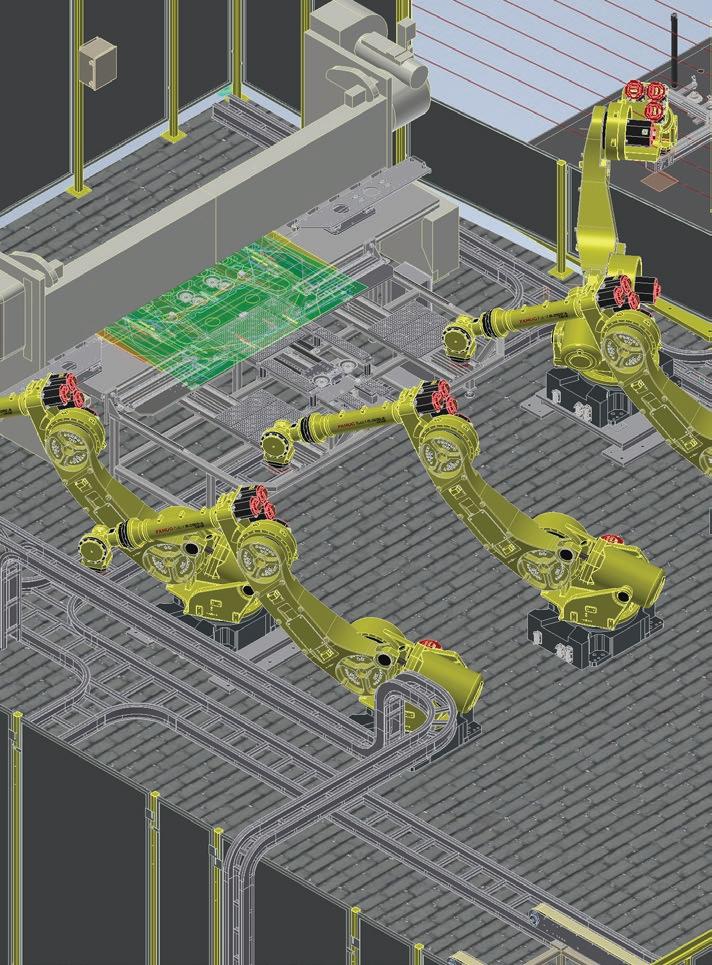

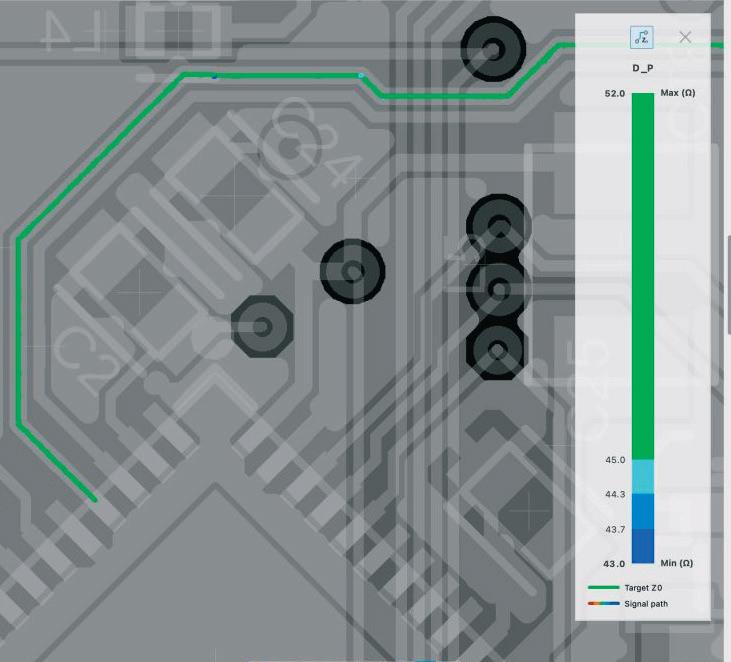

SIGNAL INTEGRITY EXTENSION LAUNCHED FOR FUSION 360

Autodesk has announced its new Signal Integrity Extension for Fusion 360, powered by Ansys to enable users to analyse PCB electromagnetic performance.

The results are rendered with a coloured gradient, enabling designers and engineers to easily identify problematic signal paths and violations, make design updates and deal with any signal impedance mismatches that they find.

Fusion 360 Signal Integrity Extension should enable users to deliver compliant smart products, reduce development costs and shorten time to market.

The new extension is designed to assist them in making sure that their products’ high-speed, RF and wireless capabilities meet design specs and are compliant with a range of industry standards, directives and rules.

It was also developed to help minimise costly PCB physical testing and board respins, by giving users immediate access to feedback on their design’s electromagnetic performance and thus reducing project timelines.

Fusion 360 Signal Integrity Extension offers simple input parameters and configuration to empower engineers to select signals of interest for fast, ondemand analysis, explore their design and inspect parameters that characterise highspeed signals, such as propagation delay, trace length, impedance and coupling.

Additionally, users should be able to manage and control impedance for every transmission line throughout a board, for a distortion-free and optimal high-speed performance design, and visually identify

any potential impedance or coupling issues, thanks to a superimposed colourcoded overlay on 2D PCB designs.

“What we want to do for manufacturers is improve the collaboration, help them design things faster and help them do more design exploration, so they can get more innovation in a shorter time,” said Autodesk VP of industry strategy Srinath Jonnalagadda, speaking at the company's Autodesk University 2022 event.

“With this simulation extension, we want to make sure that design insights are readily available for engineers at the time when they are doing the design. The extension is able to give real-time insights, so the designers can figure out how to optimise their product and printed circuit board designs,” he said. The new extension is now available for a 14-day trial. www.autodesk.com | www.ansys.com

Photocentric unveils Liquid Crystal Titan

Photocentric, inventor of LCD 3D printing, recently took the opportunity at Formnext to show off parts created by the Liquid Crystal Titan, its largest 3D printer yet.

According to company executives, the machine has been developed to combine large size, high resolution, fast print speeds and high accuracy.

The Titan is equipped with a 700 x 395 x 1200 mm build volume and a 91µm pixel pitch resolution, and also features an 8K 32-inch LCD screen. With it, the company aims to

ROUND UP

Materialise has announced that seven new partners have joined its CO-AM software platform to support design and preprinting automation, traceability, printing and post-processing for 3D-printed parts.

Materialise Magics has also been integrated into CO-AM www.materialise.com

Authentise has released its Digital Design Warehouse platform, which was developed to help organisations establish more cohesive additive manufacturing initiatives, by bringing into one place insights into AM processes collected from disparate silos and teams www.authentise.com

3D Systems and ALM have partnered to expand access to industry-leading 3D printing materials, in an agreement that involves the addition of 3D Systems’ DuraForm PAx material to ALM’s portfolio. This will give ALM customers access to a unique copolymer designed specifically for use with SLS technologies www.3dsystems.com

make large-scale production a reality for additive manufacturing applications in automotive, transport, creative arts and merchandising.

Photocentric also announced it will be delivering ceramic production parts in Alumina and Silica and benefiting from extensive experience in photopolymer and LCD-based, large-scale manufacturing to mass manufacture Alumina parts. It is also partnering with Loctite and BASF Forward AM, to develop and validate high-performance engineering-grade resins for industrial applications. www.photocentric group.com

Dyemansion has announced its Powerfuse S PP postprocessing station for vapour polishing, in a move designed to bring surface and material improvements specifically to parts 3D-printed in polypropylene, making new use cases possible for this material www.dyemansion.com

Cloud Factory has raised £1.7 million for its direct metal 3D printing technology to manufacture sustainable jewellery and develop its online jewellery platform. Through its use of additive manufacturing, the company defines itself as the world's first zero-waste jewellery factory www.cloudfactory.jewelry

DEVELOP3D.COM DECEMBER 2022 / JANUARY 2023 11 NEWS

Fusion 360 Signal Integrity Extension is designed to help users deliver safe, compliant smart products

The Liquid Crystal Titan is Photocentric's largest 3D printer yet

additivemanufacturingstrategies.com networking & intelligence summit NEW YORK | february 7-9, 2023 THE VOICE OF 3D PRINTING 3dprint.com The Leading Source of Industry Analysis, Market Forecasting and Data for Additive Manufacturing smartechanalysis.com

Since designers are now expected to be conscious of their role in sustainable product development, an awareness of emerging ways to remove carbon from the design process is paramount. Reducing our dependence on fossil fuels is one of the key steps in decreasing our carbon footprint — and adopting biopolymers may be the answer.

So what actually are biopolymers? Crude oil is typically used to create virgin plastic. Crude oil is refined, polymerised and processed to form pellets used to injectionmould plastic parts. Biopolymers are derived from renewable sources. Instead of crude oil, they are created from a renewable feedstock, in the form of crops, waste cooking oils or algae. These renewable feedstocks are processed at a biorefinery, polymerised and similarly processed to form pellets for injection moulding.

Renewable feedstocks are a carbon sink, as they absorb carbon throughout their life. As a result, biopolymers exhibit a negative carbon footprint and contribute to the reduction of carbon. Replacing virgin polymers with biopolymers helps to build a circular economy, removing the need for fossil feedstocks like crude oil.

SAYING NO TO VIRGIN PLASTIC

The primary advantage of biopolymers is that they remove the dependence on crude oil and replace it with renewable sources that contribute to the reduction of carbon. Before biopolymers, the nonfossil alternative to virgin polymers was a mechanically recycled polymer.

Mechanical recycling starts with the waste plastic that is collected from your door. Local councils send it for sorting, cleaning, shredding and reprocessing, where it becomes pellets for injection moulding.

The primary limitation of mechanical recycling is the lack of complete cleanliness and traceability. For these reasons, mechanically recycled polymers cannot be used to manufacture medical or food/

drink-safe products. Biopolymers, by contrast, have cleanliness and traceability attributes identical to virgin polymers.

IDC recently worked with Reuser to develop a reusable coffee cup lid. BioPolypropylene was used to manufacture the product, which has a negative carbon footprint, offers mechanical and thermal properties nearly identical to that of a virgin Polypropylene and is fully recyclable at the end of its life. IDC’s sister company Naiad became the first UK manufacturer to use Bornewables’ bio-Polypropylene within the food and drink industry, while the use of biopolymers contributed to Reuser’s mission of replacing the disposable, single-use food and beverage system with innovative reusable solutions. The fully recyclable bio-Polypropylene, with an established end-of-life infrastructure, formed a circular economy.

Much of the attention around sustainability is focused on one-off projects where face masks or plastic bags have been recycled to form an exotic piece of art or furniture. While this removes single-use products from landfill, the elaborate and laborious processing means this can never be adopted at a scale where the positive environmental impact would be meaningful.

Earlier in 2022, Philips launched the world’s first breakfast set made from bio-based plastics. The toaster, kettle and coffee machine were manufactured from biopolymers derived from recycled cooking oil. It is hoped that other manufacturers will follow suit and embrace the use of biopolymers at scale as a direct replacement for fossil-based plastics.

Injection moulding biopolymers is no different from virgin polymers. No special set-up or processing is required, and mass production can begin immediately using existing infrastructure.

WHAT’S STOPPING US?

The primary drawback of biopolymers is cost. While virgin Polypropolyne costs roughly £2/kg, bio-Polypropolyne costs roughly £3/kg. The cost of biopolymers is

largely driven by the expensive and lowyield processing of renewable feedstocks, but with time and economies of scale, the price gap between bio and virgin polymers is expected to close significantly.

In addition, the price of virgin polymers is linked to the price of crude oil, which is only going to increase as stocks are depleted. While there are thousands of virgin polymers available with properties to suit almost any application, there are only a handful of biopolymers to choose from. Bio Polypropylene (PP), Polyethylene (PE) and Polyethylene terephthalate (PET) are among the most common. These polymers have a limited number of useful applications.

Chemical recycling is an emerging process that can produce a wider range of available bioplastics. Here, non-mechanically recyclable waste plastics are broken down into hydrocarbons that are polymerised and processed to form virgin-equivalent biopolymers. This will play a key role in reducing the quantity of conventionally unrecyclable plastic sent to landfill.

The use of biopolymers is supporting the push for a circular economy that isn’t dependent on crude oil. As the processing of renewable feedstocks develops and economies of scale reduce raw material costs, the use of biopolymers is set to have a significant positive impact on the plastics industry.

ABOUT THE AUTHOR: Luke Williams is a Senior Design Engineer at IDC. He plays a key role in design for manufacture, in particular design for injection moulding. As well as detailed design, this involves polymer selection across a range of parts for medical and industrial devices. Recent work has involved the analysis and implementation of biopolymers to deliver sustainable solutions

DEVELOP3D.COM DECEMBER 2022 / JANUARY 2023 13

COMMENT

Replacing virgin polymers with biopolymers helps to build a circular economy, removing the need for fossil feedstocks like crude oil

Design and manufacturing pros who want to play their part in creating more sustainable products need to keep a close eye on biopolymers, writes Luke Williams of industrial design consultancy IDC

Current numbers simply don’t add up if the manufacturing sector hopes to maintain a fit-for-the-future workforce, writes our columnist SJ. Here’s some advice for employers keen to recruit new talent to the sector in 2023

My first written sentence, made with a shiny yellow number 2 lead pencil, was an algebraic equation.

Raised by a math teacher, my mother taught me the language of numbers – and the stories they told –before I even learned to ride a bike.

In this column, I have another story to tell, about hiring in advanced manufacturing, and in this one, the numbers just don’t add up. Or, as members of the Gen Z cohort sometimes say: “The math isn’t math-ing.”

I recently had the honour and pleasure of attending the International Conference for Additive Manufacturing. After their sessions, I made a point of speaking to panellists about their perspectives on the job market.

I’m happy to report back that many were optimistically hiring. They had “tons of positions open”, they told me. I expressed surprise because, from a personal perspective, I’ve been seeing record layoffs and industry colleagues struggling to get rehired. For the last year, my LinkedIn feed has been filled with contacts being laid off, companies going bankrupt and start-ups disappearing almost overnight.

The more sage members of the community were quick to point out that many of the layoffs were happening at specific types of companies, and in particular, those that manufacture machines.

In other words, it’s simply a reflection of “too much supply, not enough demand”, they told me, and not something for the advanced manufacturing sector as a whole to be overly concerned about.

At the same time, one of the more prestigious firms reported continued record growth for the industry, increasing numbers of patents, and even hinted at potential job security into the future, thanks to the large demand they were seeing for employees.

From my perspective, this last point is where “the math isn’t math-ing.” Why, I wondered, am I seeing this complete disconnect between the dismal situation seen on my LinkedIn account and hubristic industry reporting?

MAKE IT ADD UP!

It’s time to put our yellow number 2 pencils to work. I imagine the math problem might read something like this: “In the manufacturing industry, 25% of employees are more than 55 years old and the median age of the workforce is 44.5 years. If a person is selected at random from this industry, what is the probability that they are under 30 years of age?”

Now, I don’t need a calculator to tell you how bleak that picture looks for the future of advanced manufacturing. I’ve heard first-hand the frustrations of young high school students, worried about their future earning potential; of parents, who are scared to see their child begin a career that might get outsourced before it has barely begun; of employers, representing organisations both large and small.

Businesses in the US are disheartened by the unsustainable, over-inflated salaries required to retain top talent. In the UK, they are struggling to back-fill a talent pipeline hamstrung by immigration challenges as a result of leaving the EU. And companies in both the US and the UK all face fierce challenges when it comes to creating more diverse workforces.

MY ADVICE TO INDUSTRY

But, as I stand in a weird gap between people close to retiring and people entering the workforce for the first time, I have a unique perspective to offer companies looking to attract and retain talent. My advice comes in three parts.

First, “If you can see it, you can’t be it.” Statistically, only 180 young players out of a pool of 1.5 million have the chance to become a pro footballer in the UK. Yet many take those odds, because they see the sport everywhere. If you want to attract and retain a workforce of skilled employees, create programmes that are widely seen. Penetrate spaces popular with young people and market career opportunities on social media: Snapchat, TikTok, or Instagram. Meet them where they are most comfortable and most receptive to your message.

Second, “Make it bite-sized.” This upcoming generation is one accustomed to instant gratification, because its members were born and raised on the internet. They’re not interested in extensive 401k benefits, life insurance, retirement programmes/assistanceship, or stocks with long vesting periods. Instead, offer them achievable and clearly outlined goals to achieve regular promotion faster. Offer them healthcare benefits for their pets (because having children in this economy? Absolutely not.) For those that do have children, offer a generous family leave policy – for both partners. Give them lots of options, but make them bite-sized. This generation loves to pick and choose, creating a benefits package tailored to their wants and needs.

Third, “Be fuckin’ for real.” That’s Gen Z slang for “be authentic and cut the bullshit.” This starts with company culture. The younger generation wants to work for a company where personal values align with company values and overall mission. Rewrite your company story, find a purpose. In 2023, you need to “eat, pray, love” your company culture. It’s not enough to simply slap three keywords on an inspirational landscape and hang it on a wall in the break room. No, you have to change your company culture to be more open and responsive to the social issues that this generation cares about, like climate change, mental health and DEI (diversity, equity and inclusion). My mother’s favourite algebraic equation is y = mx + b, used to describe the slope of a line. Those four characters tell a story about who crossed what and where, how fast or how slowly, upwards or downwards. At some point, we have to draw the line for ourselves. I remain optimistic that change always brings a positive slope.

ABOUT THE AUTHOR: SJ is a metal additive engineer aka THEE Hottie of Metal Printing. SJ’s work involves providing additive manufacturing solutions and #3dprinting of metal parts to help create a decarbonised world.

14 DECEMBER 2022 / JANUARY 2023 DEVELOP3D.COM

COMMENT

Companies in both the US and UK face fierce challenges in 2023, when it comes to attracting and retaining diverse talent

Subscribe now FREE Print* or digital Technology for the product lifecycle register.develop3d.com *Free for UK readers ($49 per annum for ROW)

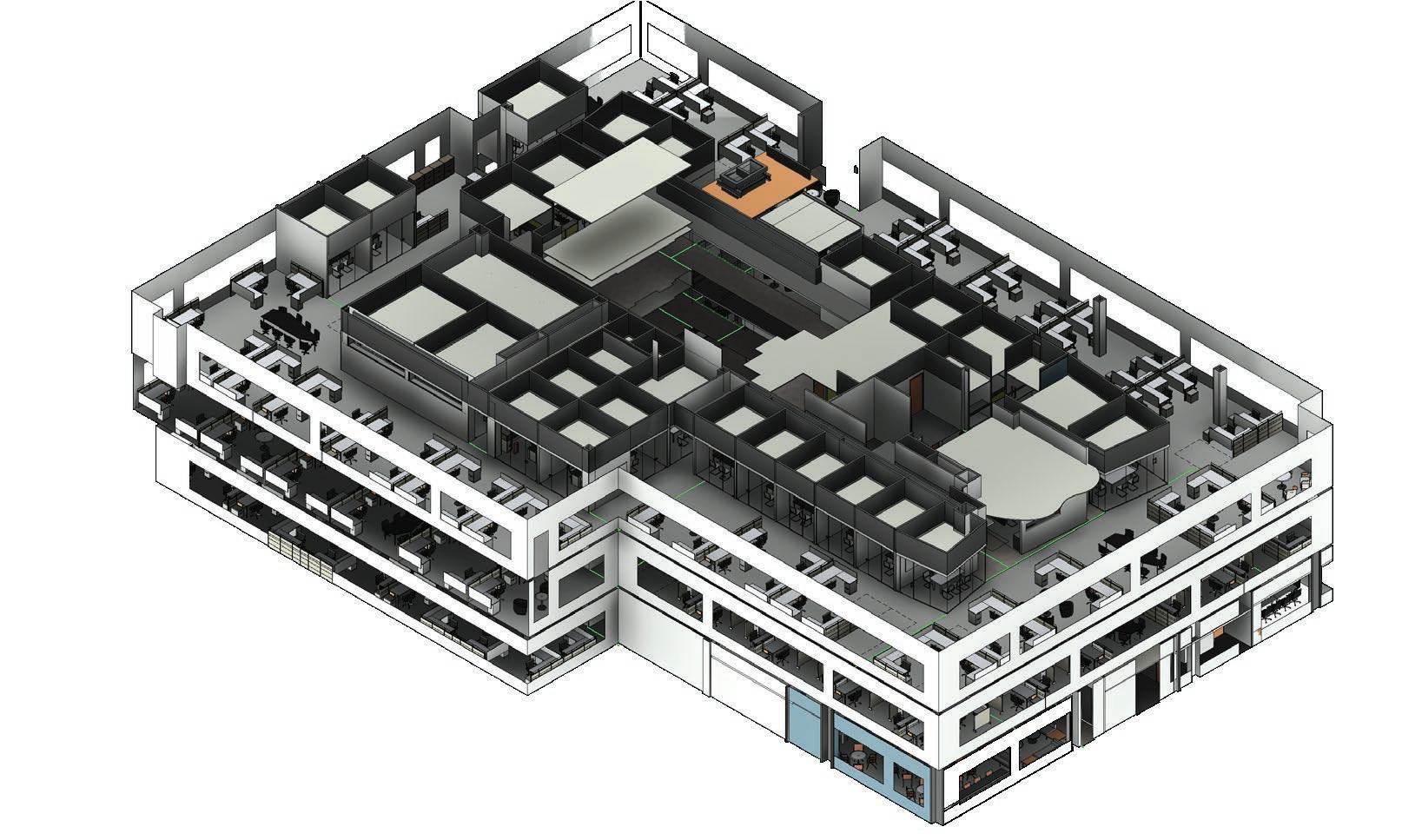

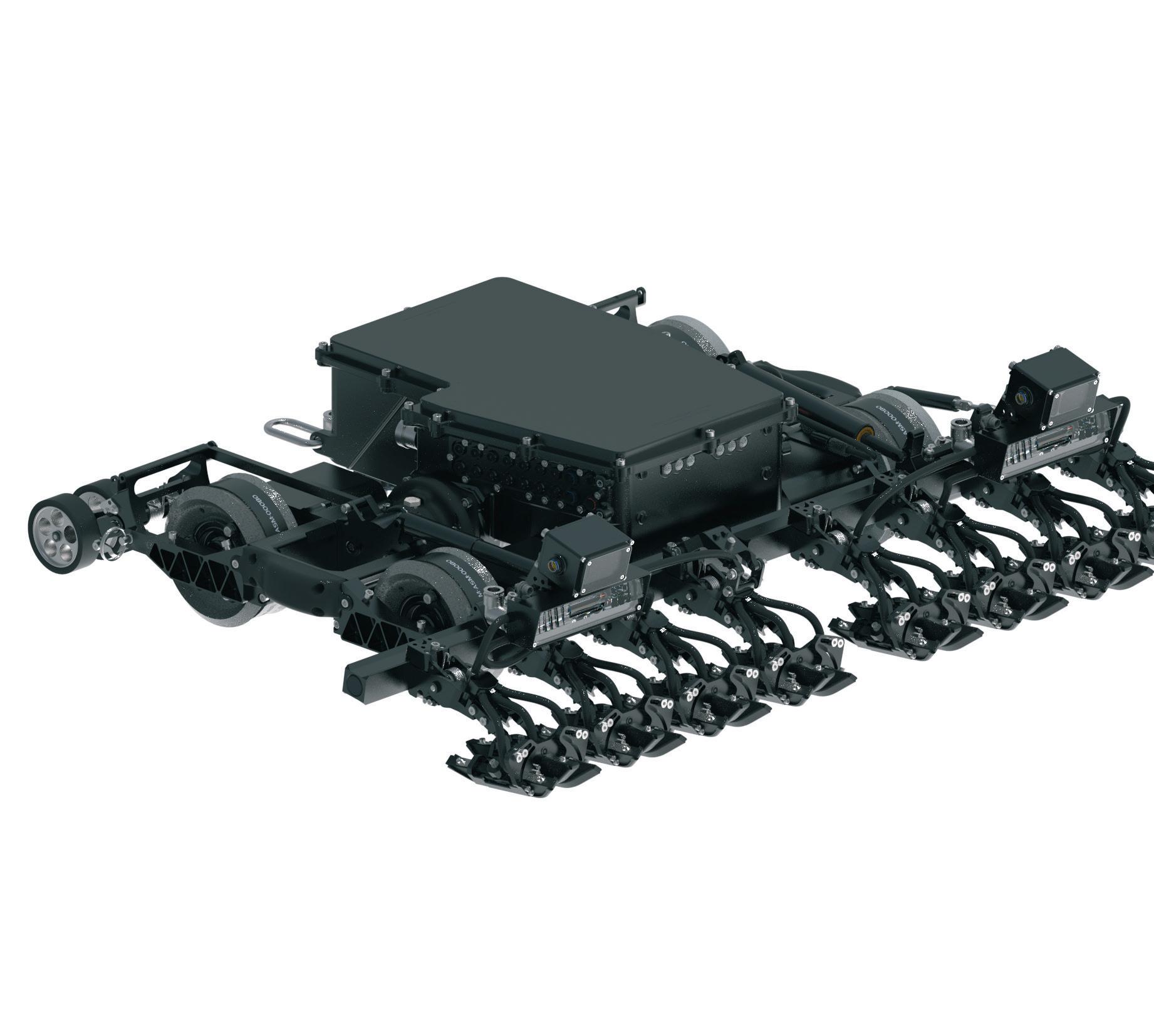

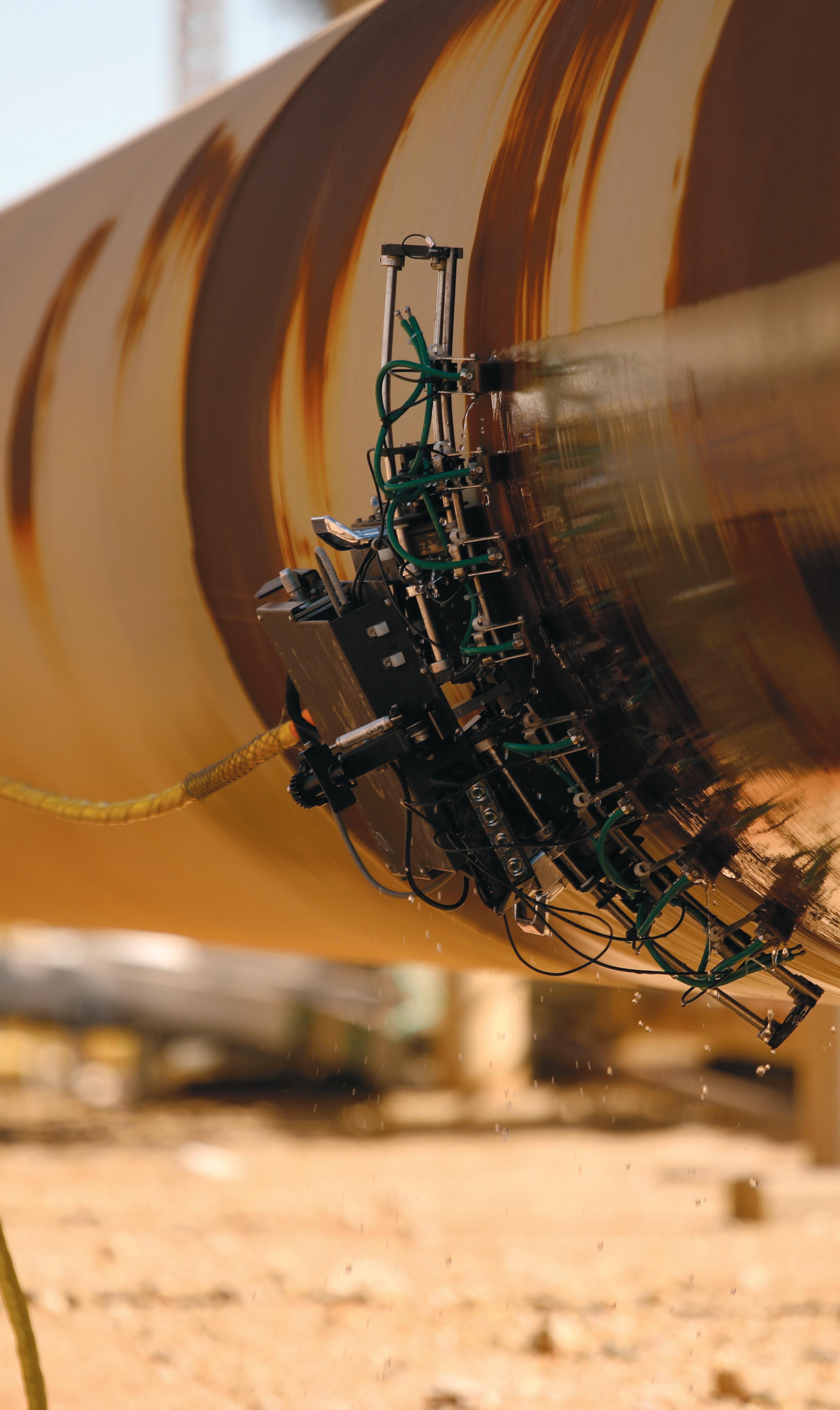

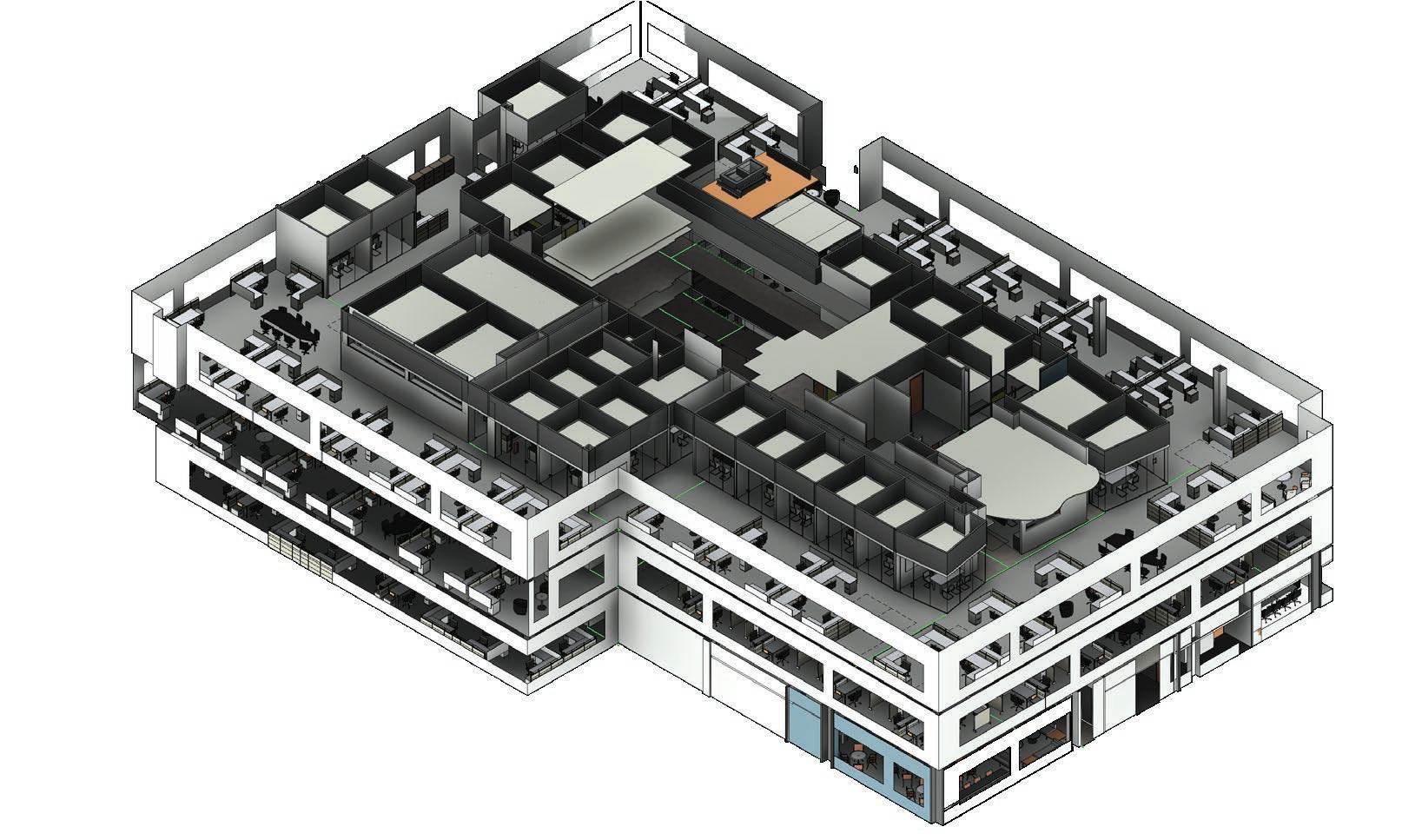

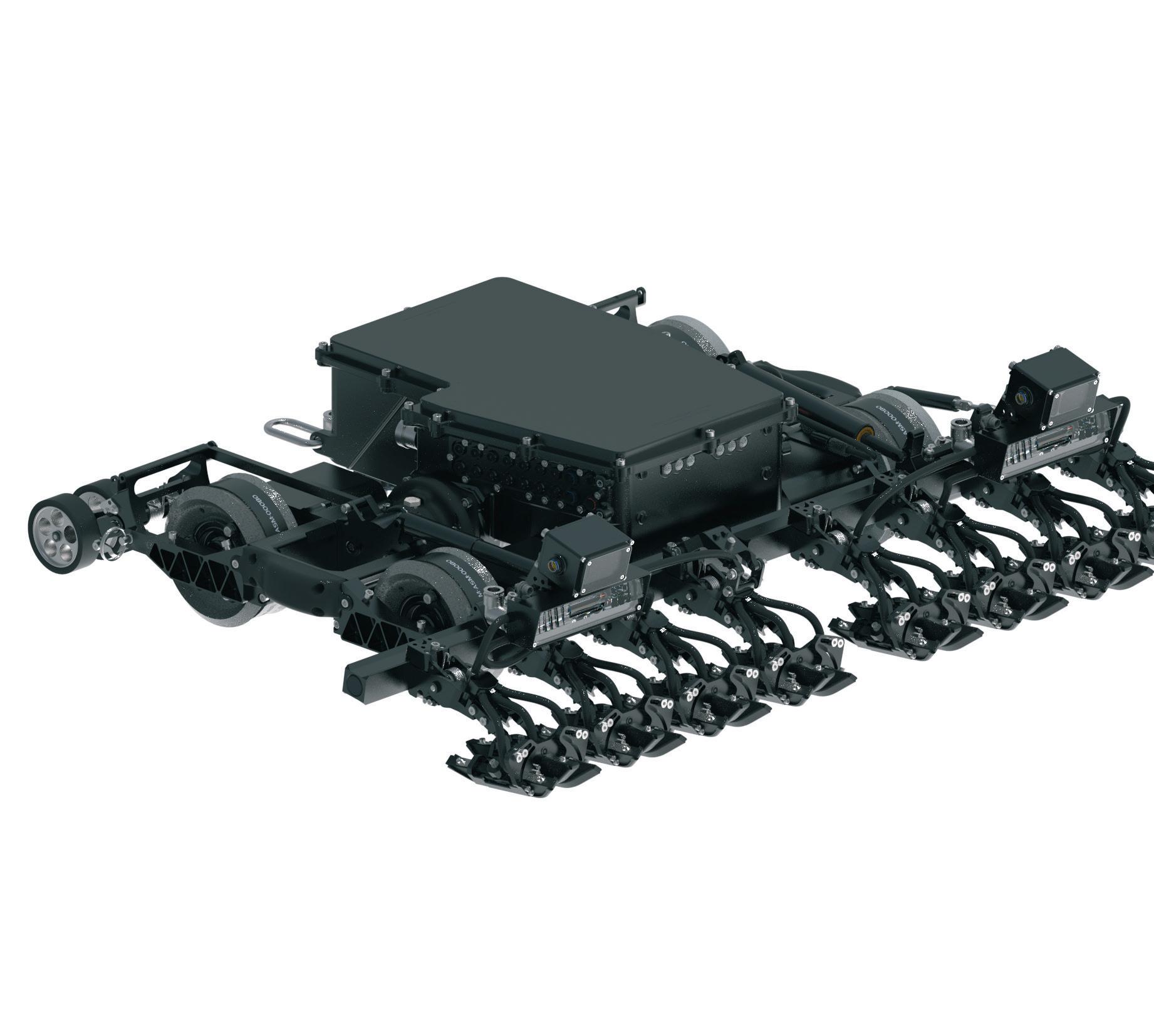

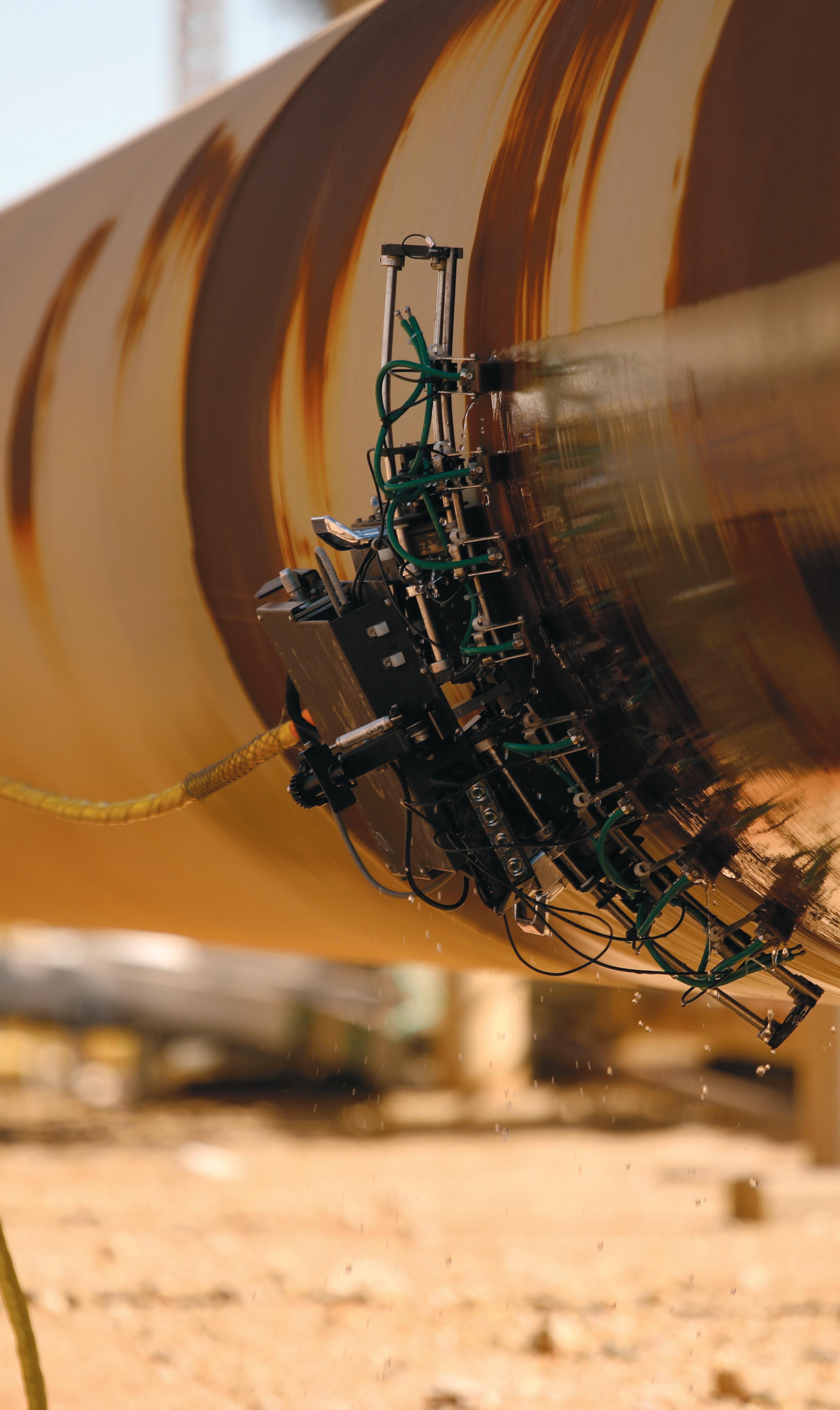

VISUAL DESIGN GUIDE TOKA 4 FROM GECKO ROBOTICS

A climbing robot developed for inspecting areas too difficult or dangerous for humans to access, including pipework and boiler systems

ALL UNDER CONTROL

Front and rear HD driving cameras provide an operator with visuals for manoeuvring around environments and for capturing an asset’s surface condition during inspection

SMOOTH TRANSITIONS

Actuation of the sensor arms enables the robot to accomplish angle transitions while still capturing necessary data, and without slowing down the process

STRONG ATTRACTION

Permanent rare earth magnetic wheels support strong asset surface adhesion at speeds of up to 9 metres per minute

ALL THE DATA YOU NEED

Capable of carrying a payload of around 56Kg, the Toka 4 can be equipped with between 24 and 32 ultrasonic inspection sensors, in order to collect a wide array of data at rates of around 39 samples per metre

16 DECEMBER 2022 / JANUARY 2023 DEVELOP3D.COM

UPWARDS CURVE

The Toka 4 has been designed for curved surfaces such as tank walls and pipework, making it a valuable tool for companies where employees perform regular inspections, in industries such as oil and gas, pulp and paper, power generation and maritime transportation

FULL COVERAGE

The Toka 4 utilises compact rotary magnetic encoders for the accurate positioning of data, allowing it to create 3D models of inspection data

DEVELOP3D.COM DECEMBER 2022 / JANUARY 2023

BBI AUTOSPORT PUSHES THE BOUNDARIES OF MOTORSPORTS AND 3D MODELLING WITH FUSION 360

BBi

By: Gregory Han

Like many origin stories , the early beginnings of the Huntington Beach, California automotive tuning company BBi Autosport can be traced back to the wide-eyed and formative years of childhood.

“It was one afternoon when my cousin and I were playing outside when we spotted a stunning Porsche 959 drive by,” recollects BBi co-founder Betim Berisha, “It was the very same car on my cousin’s favourite poster up on his wall. We later found out the driver behind the wheel was Bill Gates!”

The sighting of the supercar – one of only

292 ever built – would give birth to a lifelong obsession with Porsches that would only intensify with age, culminating in Berisha founding BBi Autosport in 2005.

Alongside designer and company CTO, Dmitriy Orlov, today BBi Autosport operates at the upper echelons of bespoke motorsports, hosting a team capable of not only tuning and customizing the “phenomenal, dynamic, wildly versatile canvas” of Porsche vehicles,” but also designing vehicles uniquely their own in spirit and performance.

Designing “The Pig”

BBi’s talent for conjuring one-of-a-kind Porsches is perhaps best embodied by the creation of the Hoonipigasus, a beastly 1,400 HP mid-engine AWD rally racer conceived from the ground up in partnership with Hoonigan Racing for rally car legend, Ken Block. Loosely inspired by the Porsche 911, “The Pig” – as it is fondly referred to by its creators – was to be let loose on the death-defying winding course of Pikes Peak International Hill Climb for its 100thanniversary race with the hopes of breaking records on its way up to the race’s 14,100 feet peak.

The Pikes Peak trial was preceded by BBi’s own race against time. Battling an “insane” schedule compounded by long lead times further complicated by the pandemic, BBi found themselves designing, engineering, fabricating and testing The Pig in parallel.

Traditional tools wouldn’t allow each of the team members to work concurrently and collaboratively without “stepping on each other’s toes”. The Pig not only had to get assembled to roll up to the starting line by race day, but had to be engineered to the most exacting standards.

With a mere 0.04mm margin of error for their measurements, the team had to factor in every aspect of every part to line up with precise accuracy to bring their vision to life.“Producing parts of that

Autosport explains how Fusion 360 enabled them to design the Hoonipigasus, “a car that can do nearly anything.”

Sponsored content

quality is a daunting task when dealing with the tight deadline we were under,” says Berisha.

From chaos into collaboration

The need for a CAD/CAM solution that would allow the BBi team to develop products concurrently and outside the boundaries of traditional 3D modelling software made Autodesk Fusion 360 the ideal tool set, one that could bring all of their aggregated data into one centralized location. They’d find simplicity in using a cloud product development tool integrating CAD, CAM, CAE, and PCB to turn prototypes into production-ready parts.

“Autodesk Fusion 360 enabled us to move seamlessly through every stage in our development process, whether we were designing an engine, chassis, or even the smallest component,” says Betim. Tools like generative design enabled Betim and his team to run flow analysis to generate recommended outputs. They then used this data to design parts manufactured to their desired specifications.

“Fusion 360 allowed Dmitriy, to bring all of our aggregated data into one centralized location,” he says, “We could then all design and build in parallel by prioritizing tasks based on their lead times. For example, making moulds and tooling for bodywork was our first priority because it would have the longest lead time.”

Thesecarscan doanything: hillclimbs,offroad,iceracing, rallyracing, enduranceraces BetimBerisha, Founder,BBi Autosport

“Collaborating on the cloud turned the chaos into organized chaos, Fusion 360 enabled us to design, validate, build and get straight to the racetrack very quickly.”

The motorsport to consumer product pipeline

Unfortunately, even with the greatest plans in place, motorsport races are unpredictable by nature. The Pig would drop a valve before even qualifying for the race, leaving a disappointed Block and the BBi team to look ahead toward the 101st “Race to the Clouds.”

Though disheartened, Betim remains upbeat about the lessons learned leading up to the race and how they’ll translate to their consumer products division.

“There’s a trickle-down effect from our motorsport division to our consumer product division,” notes the Porsche-loving-kid-turned-BBi-founder. “We found with almost the click of a button, Fusion 360 is capable of exporting our 3D models to our CNC machine to manufacture right then and there, ending up with a finished part that is ready to hit the racetrack or ship out the door to our client.”

As for Pike’s Peak, “We’ll be back. A little wiser, always humble, but no less hungry.”

Learn more about Fusion 360 here: https://www.autodesk.com/products/fusion-360/

Sponsored content All images courtesy of Autodesk

MORE THAN MEETS

20 DECEMBER 2022 / JANUARY 2023 DEVELOP3D.COM

MEETS THE EYE

DEVELOP3D.COM DECEMBER 2022 / JANUARY 2023 21 COVER STORY

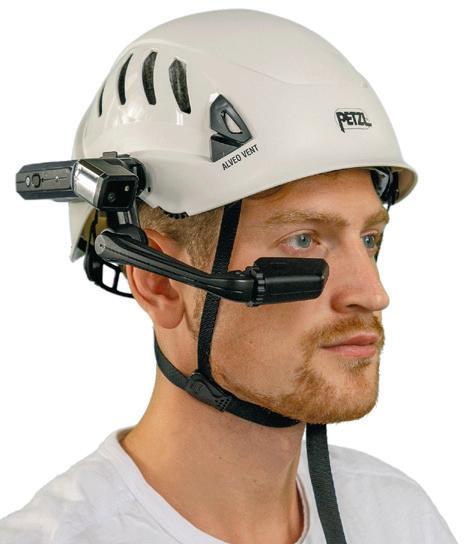

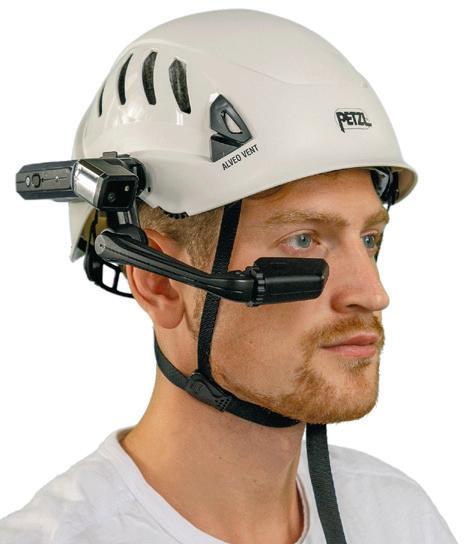

Put yourself in the steel-toe capped work boots of a lift maintenance engineer for a moment.

Responding to an issue, you put on your new head-mounted, mixed reality headset, which is going to show you how to identify and fix the problem through vivid, overlaid graphics. You stride towards the elevator in question – and whoosh. You failed to spot the edge of the lift shaft and down you plunge.

It’s not just the cost and complex set-up associated with new head-mounted displays that are off-putting, says Noah Balmer. It’s also the risks they pose when a user has bright lights blasting both eyeballs.

“Yes, you can see through it – but it’s like when you see something in your peripheral vision, for example. You know, something’s there, but you have to actually look at it to see it. And when you’re looking at something, you have blind spots everywhere else.”

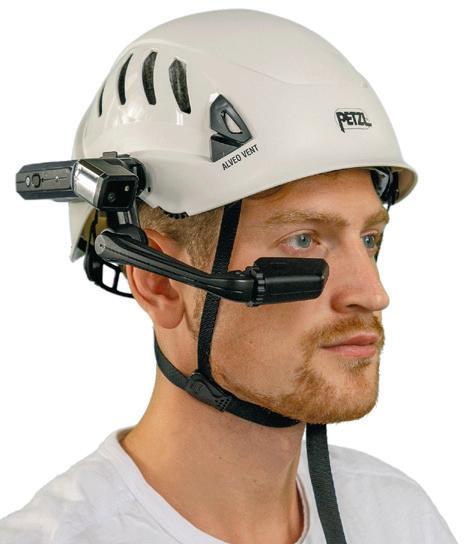

Balmer is director of product design at RealWear, a company that since 2016 has produced head-mounted displays that position a screen close to the wearer’s eye, but leaving their view unencumbered. Marketed as ‘assistive reality’, RealWear’s products are built solely with industrial use in mind.

For most industrial maintenance workers, he says, the jump from laminated print-outs of work instructions, say, to hi-tech, mixed reality headsets is far greater than you might imagine.

“With our device, it’s a lot easier for people to wrap their head around, or have it wrap around their head!” laughs Balmer. “We can just explain to them that this is a normal display. It doesn’t have holograms that dance around, you don’t need to develop new models, or digitise every schematic you have in your factory.”

RealWear’s products, such as the latest Navigator 500, offer a screen similar to a digital viewfinder on a camera. Once your eye is up against it, it looks like a big display. It’s often compared to a hands-free mobile phone display.

For someone needing to read page 132 of a PDF, while wearing gloves and goggles inside of a crawlspace, having to consult a document or a tablet is not ideal. A bunch of laminated papers is still the norm at many companies, according to Balmer. “They wake up in the morning, and they print out a bunch of crap. And then they laminate it. They’re all there fighting over the lamination machine!”

The Navigator 500 connects to WiFi or can be fitted with a modem. It can connect, for example, to a Microsoft Teams call, its camera capable of putting an expert on the other side of the world at eye level with the problem at

RealWear’s handsfree technology can quickly get expert eyes on a technical issue, via a standard Microsoft Teams call

22 DECEMBER 2022 / JANUARY 2023 DEVELOP3D.COM COVER STORY

» Hands-free access to documentation is a godsend for workers operating in awkward or high-risk environments. Stephen Holmes talks to RealWear, a company behind wearable technology that prioritises industrial needs and winning fans in work environments ranging from oil rigs to operating theatres

hand. Or it can bring up video for a walk-through of how to conduct a repair via its screen.

While many new augmented and mixed reality (AR/ MR) headsets have been launched, few companies yet have detailed models for their service workers to use.

“Most of the time, they’re printing out a PDF,” says Balmer, “There’s no way they’re gonna get to the next level of augmentation.”

UP TOP DESIGN

Before RealWear even started, its founders were already working in different companies, learning about optics and head-mounted devices. Using Human Factors and User-Centred Design principles, plus all they had learned about optics and how the human eye works, they began to build industrial headsets.

A lot of this is based around the shape of the human head, and the fact that what might be a perfect fit for one person may be huge or a tight squeeze on another, given their very different head dimensions. Eye dominance also plays a role, especially for a product that might be worn all day, hence RealWear’s display arms can be flipped to accommodate this.

In an industrial space, there’s also the challenge of PPE – personal protective equipment. Many countries have different hard hat designs to meet varying safety certifications, so everything is slightly different.

(RealWear offers around 50 different clip designs for

different hard hats.) And you can add to this mix a wide range of use cases. A wearer might need ear defenders, for example, but then they can’t wear the device under the brim.

A lot of this product development work and identifying specific problems comes down to physical prototyping. At RealWear, much of this is down to the framework set out by Balmer’s predecessor.

“The guy that I replaced, Stephen Pombo, was a pretty famous guy around this space. He was a model maker in the Bay Area for 30 years. He worked on original models for Apple computers and for Atari. He worked on some Star Wars assets for Industrial Light & Magic,” says Balmer.

“He hired me, and long story short, I realised that sketching models, scratch builds, these kinds of things, are way more important than people realise.”

The development process at RealWear begins with masses of brainstorming and consideration of specific customer requirements, but very quickly, moves into physical prototyping.

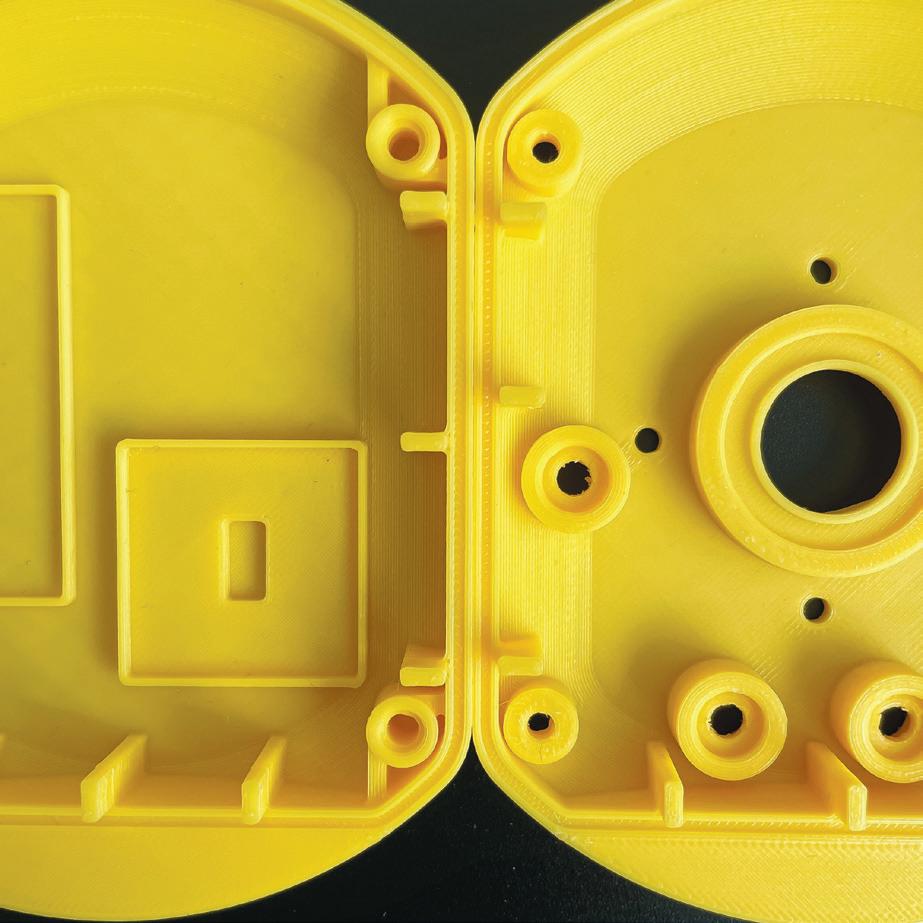

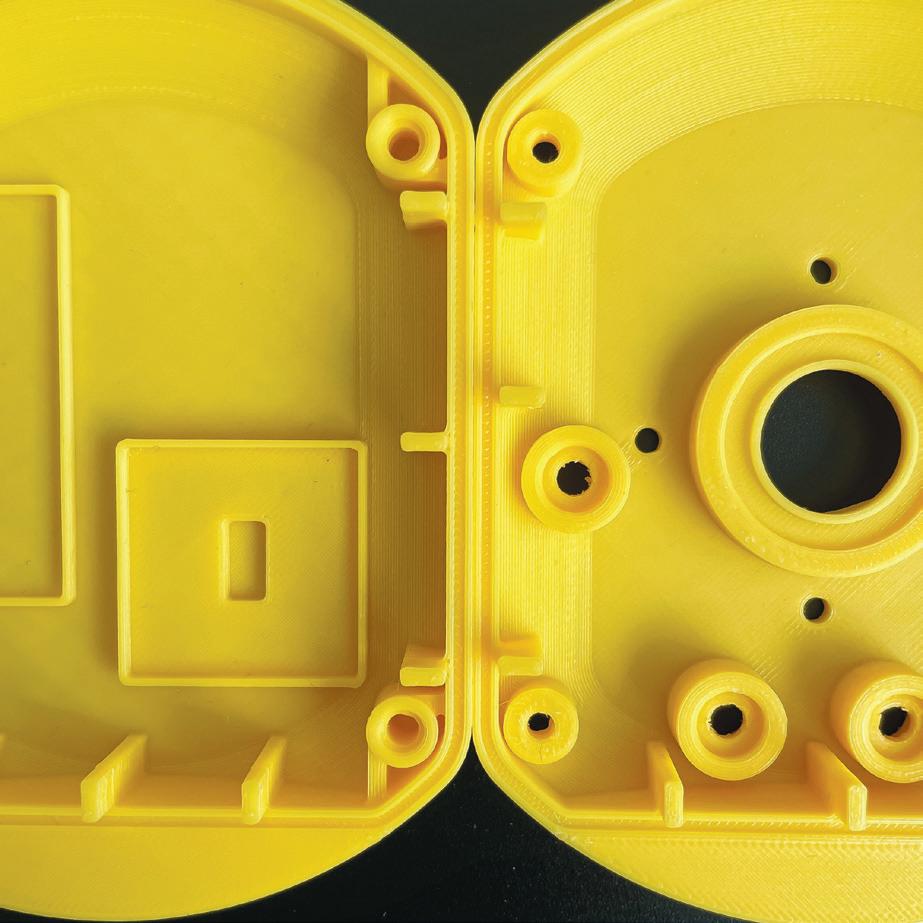

Balmer models most of the concept designs in Solidworks, and then 3D prints quick models for assessment on a desktop Prusa in his home office, in order to get an idea of how something might work or sit on the headset.

For presentation models, he steps up the design to the two workhorse Markforged Onyx 3D printers at RealWear’s design studio. “Those things just print every time. I’ve done like a 26-hour build lots of tiny parts –and it just works every time. It’s miraculous!” he says. These prototypes are vitally important, he says.

“You can have bigwigs in a room talking, and you’re not gonna get anywhere until you put something on someone’s head and see if they like it or not see if it hurts their brain! Part of what I do here is make a ton of working models, and then test them on people. And that’s really, I think, the key to success for anything that goes on the human body, especially.”

A lot of Balmer’s role involves concepting, research and user studies. His design team, meanwhile, boasts plenty of CAD geniuses.

“I’m pretty good, but you know, there are those masters,” he says. “They’ve been doing it for 10,000 more hours than me, and I’m not going to catch up anytime soon while I read all these emails!”

A new display in a different form factor might begin life as a development circuit board hanging off a headset made of cardboard and 3D-printed parts. This, according to Balmer, is because he doesn’t want to be married to any single idea.

“If I make a model that takes two months, I’m really going to have to make it work, you know? But if I make it out of cardboard and I show it to people, they’re not

● 1 Lightweight and rugged, RealWear headsets can handle long hours in difficult environments

● 2 Ball joints allow for perfect screen positioning, even when working in cramped conditions

● 3 Thorough concepting work is key to achieving the best fit and comfort levels in RealWear headsets

DEVELOP3D.COM DECEMBER 2022 / JANUARY 2023 23

1 2 3

‘‘ This is a normal display. It doesn’t have holograms that jump around, you don’t need to develop new models, or digitise every schematic you have in your factory ’’

worried that there’s a big investment. If I show it to the CEO, he’s not worried that we’re gonna lose hundreds of thousands of dollars, because we have to zigzag from this specific concept,” he explains.

“It doesn’t feel scary to them, because it’s just like, ‘Oh, it’s fun.’ It’s like a costume and it looks stupid and there’s wires hanging off it. They feel like they’re part of something.”

As the design progresses, and more models are tested, the design eventually transitions into PTC Creo for detailed mechanical engineering and production, with every element built in 3D CAD, right down to the last chip on the custom board. “In the beginning, it’s all about ‘fake it till you make it.’ Then you start getting into real mechanical and electrical engineering and it has to get more locked down,” says Balmer.

Loadbearing models are outsourced to Protolabs to be made using SLS 3D printing. CNC models are produced for final testing with all the electronics fitted in place.

The headsets feature a lot of metal components, in order to be able to stand up to industrial use. A ball joint for the display could be skimped on to save costs, says Balmer, but then you’re opening up the product to flaws. If it isn’t a ball joint, then it can’t be adjusted to achieve perfect horizontal levelling for the user.

“Why would that matter? It’s just a little bit, but I don’t know if you’ve ever mounted a TV to a wall one inch off [level] or something like that? It doesn’t feel good, like your brain has to somehow rotate five degrees. It takes more processing and brain power.” Such is the drive to achieve the best level of everyday comfort.

CLEVER COMPONENTS

The industrial settings in which the headsets are designed to be worn add further levels of complexity. Drop-tests are rigorous, while the need to balance strength with weight reduction leads to a lot of FEA work to assess the best placement of internal ribs and screws. As a result, the latest model weighs, on average, only two-thirds what its predecessor weighed.

● 4 Modular designs enable custom elements, such as this tiny modem, to be fitted

● 5 Designs need to be versatile to accommodate different combinations of helmets, visors, goggles and masks

● 6 3D printers from Prusa and MarkForged play a key role in the prototyping process at RealWear

● 7 Prototypes are created to test different variations of colour, materials and finishes

● 8 RealWear designers work fast, using sketches and scratch models to ensure that design and prototyping processes stay nimble

24 DECEMBER 2022 / JANUARY 2023 DEVELOP3D.COM

‘‘ What I do here is make a ton of working models and then test them on people. And that’s really the key to success for anything that goes on the human body ’’

6 7 4 5

Modularity is another key factor. With a huge range of add-on components and features, the headsets can be customised for all kinds of roles.

“It makes sense in this world, because we’re using components from the smartphone industry. You get a camera from a smartphone, and in two years, they don’t even make that camera anymore. It’ll be some newer camera,” says Balmer.

“And so, for a business, it actually makes sense, because you can lengthen the lifespan of the overall product by offering accessory modules to make it more powerful.”

The latest model now offers a spring-loaded metal slide switch for the camera connector unit that allows the user to swap it for a different type of camera – such as specialised wide angled or thermal imaging kit – or for something else entirely, like a laser or a flashlight.

And if it turns out that a customer has a very specific requirement, then the headset proves far more versatile, and won’t require a full redesign to accommodate those needs.

Rugged aesthetics, such as overmoulded TPU bumpers, are designed with industrial use in mind, while Balmer suggests that other glasses companies have fallen into the trap of “trying to be a fashion brand.”

Donning a RealWear headset, he says “This looks pretty silly on me, but if I’m in a factory and I’ve got goggles and gloves on, it doesn’t matter that I don’t look like Blade or Vin Diesel or something!”

This versatility is a real strength, enabling RealWear to grab the attention of professionals in a wide range of sectors. Surgeons and cleanroom professionals love the devices. This widening market means that, over time, the design team will be looking to make products even more versatile.

As well as modularity, the latest model offers different head mounting options, including a lightweight, washable, soft headband option.

“For a medic performing surgeries, this is a much better design than a bump cap, or a hard hat, or some strappy thing,” explains Balmer. “[The Navigator 500] is kind of a chameleon, in that it can have different cameras, different sensors and different mounts on it for what you need in your industrial space or in your environment.”

RealWear is more accessible than many wearable devices, with its clever design allowing for a vast range of configurations and possibilities. That is enabling the company to plan clearly for the road ahead, spotting any proverbial lift shafts well before it steps into one.

www.realwear.com

DEVELOP3D.COM DECEMBER 2022 / JANUARY 2023 25 COVER STORY 8

‘‘

’’

With our device, it’s a lot easier for people to wrap their head around it — or to have it wrapped around their head!

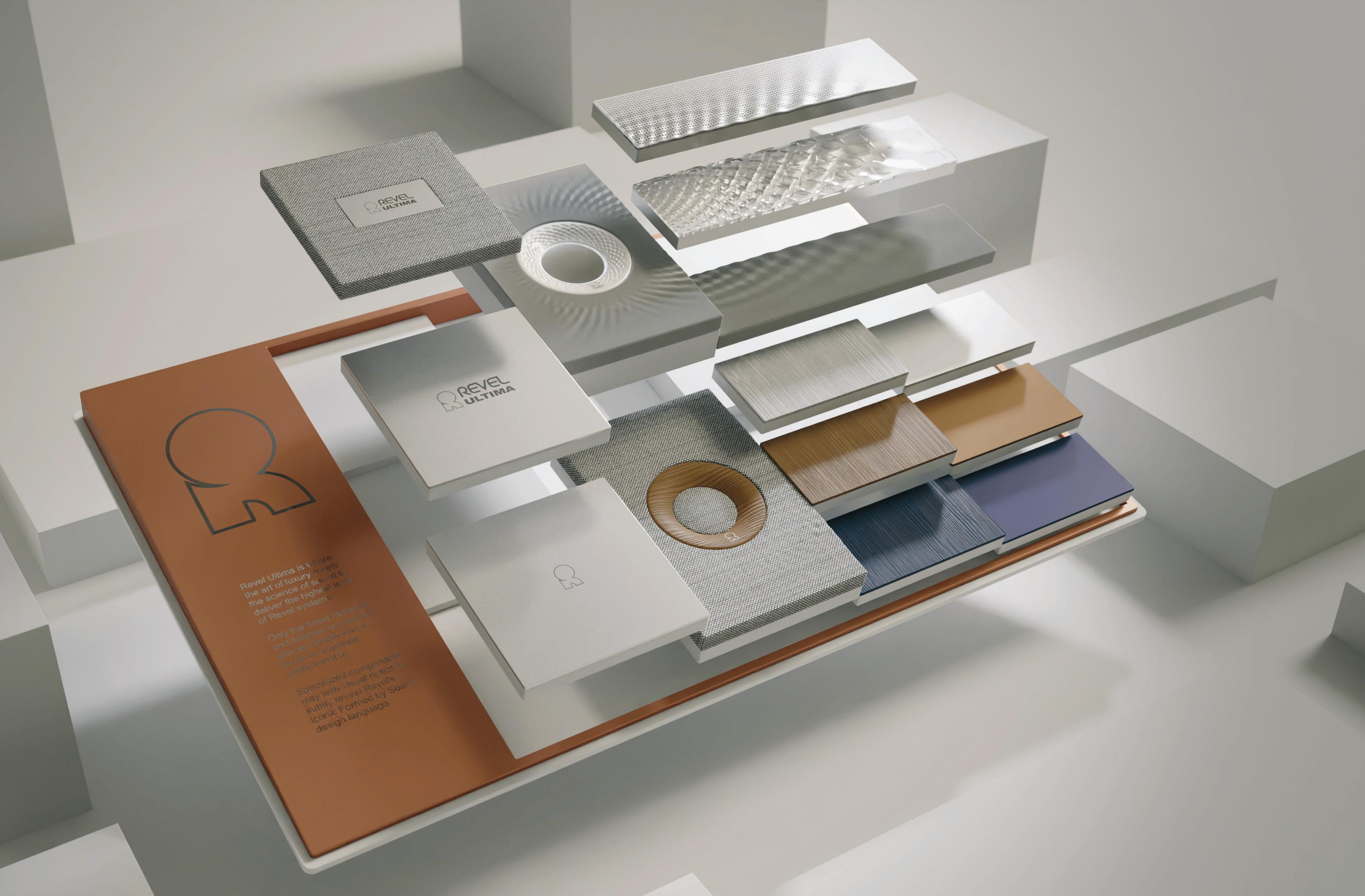

HITTING ALL THE RIGHT NOTES

Whether upright or grand, a traditional piano isn’t always a good fit for a contemporary living space. Stephen Holmes speaks to the team behind Casio’s Privia range, which has been hard at work on a design more in harmony with modern customer lifestyles

PROFILE

Casio’s bold new Privia PX design is in tune with the needs of modern musicmakers

Learning to play a musical instrument is a pastime that many pursue in their youth, only for their acquired skills to lie dormant in adulthood.

With a full-size piano taking up a considerable amount of room in a compact modern living space, former pianists face particular challenges when it comes to reacquainting themselves with their instrument.

It’s these thwarted musicians that Casio is targeting, introducing new models in its slimline home range Privia, designed to get them back to playing music again.

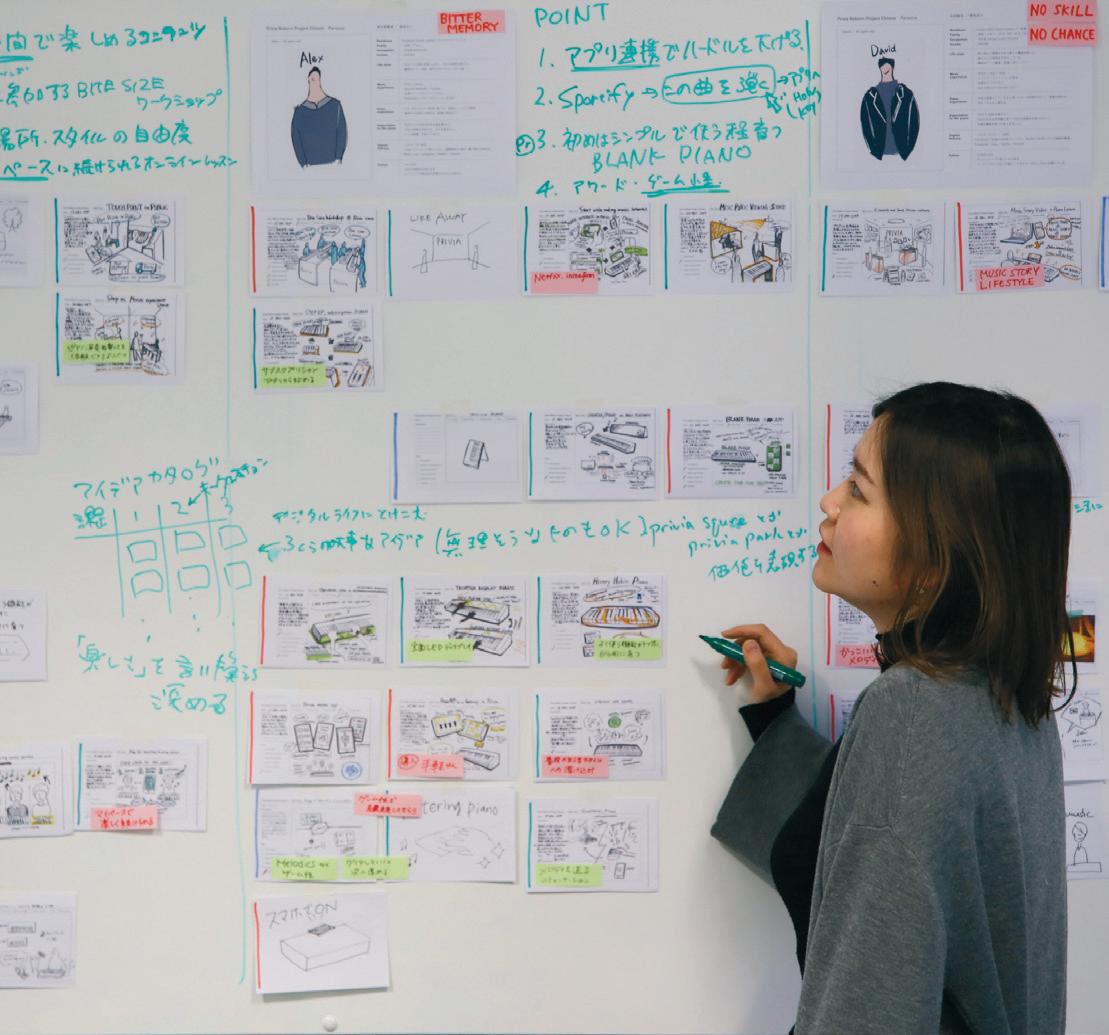

The design team is based in central Tokyo, near Shinjuku, but its research mission took it to London. Speaking to people who had given up playing the piano, team members found that a key issue was indeed the physical form of the piano. In short, traditional pianos were judged to be too large or aesthetically incongruous with home interiors.

“They felt those pianos were difficult to play with family or friends, and lonely to play alone, because the installation area is most of the time limited to the wall, so they simply gave up playing again,” says Shuhei Nakamura, an assistant manager in the product design department at Casio.

With these findings in mind, the team headed back to Tokyo and began the process of redesigning the piano to harmonise with people’s daily lives and at a scale better suited to modern homes.

ALL TOGETHER NOW

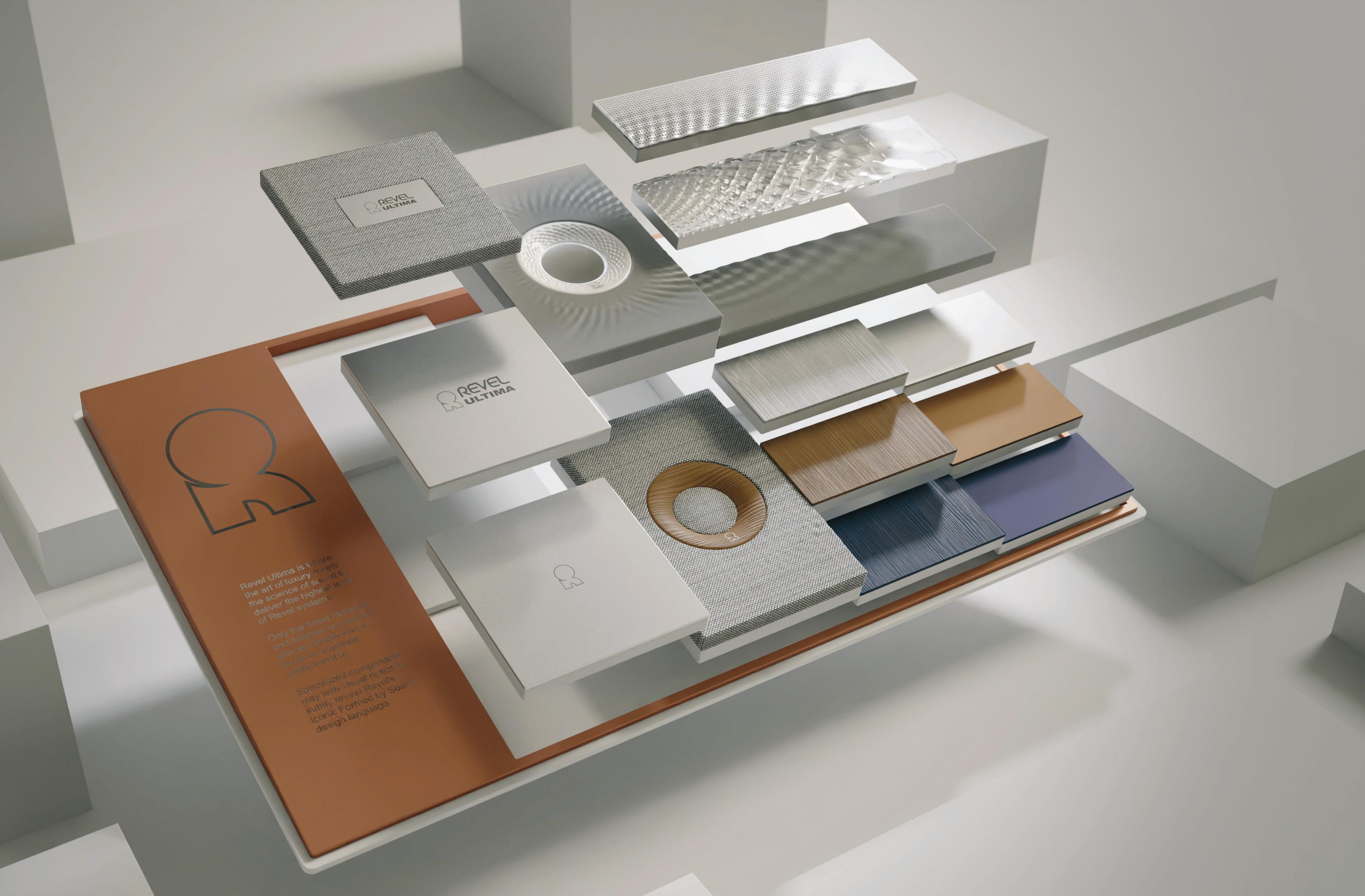

For the new PX line-up, a team of nearly 50 people was involved, drawn from several divisions dedicated to different technological aspects of the product.

Of these, six were responsible for the visual identity of the piano, working closely with a hardware design and engineering team of 10, who took charge of identifying the right materials, structure and exterior.

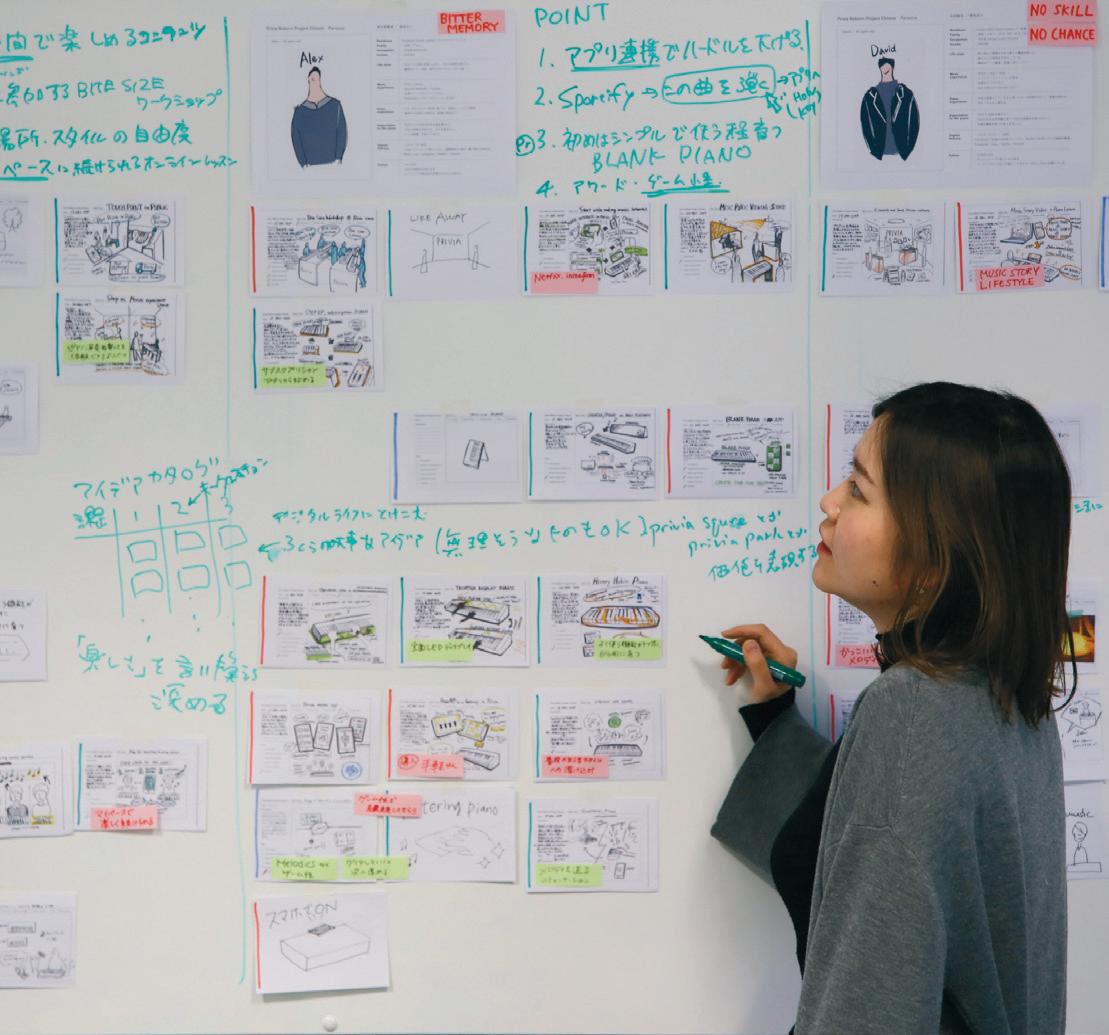

“We created four types of concept model in two batches before the final product design stage, since the new Privia series targets new users and an unprecedented market,” explains Nakamura.

A lot of effort went into the concept process, much of it involving hand-drawn sketches. These, Nakamura says, led directly to an innovative design being born: “It was a distinctive design that was unfamiliar as a piano at the stage of the internal discussion.”

Once the final design theme was chosen, the process then moved into 3D CAD with PTC Creo used to further develop

the product, to add in the electronic elements and to enable the model to be mass-produced.

The PX range includes new elements never seen before in Privia products, so there was a lot of engineering to be carried out. In particular, developing the unique stand with its three-pedal unit proved a challenge in terms of meeting Casio’s strength criteria. This demanded structural studies and CAE evaluations of dozens of variations before a final design was reached.

In addition, a newly developed housing composed of wood and resin was designed to improve the acoustic characteristics of the piano, while retaining a slim and compact aesthetic. The development team achieved this by testing several variations using computer-aided engineering tools, allowing for a functional design capable of housing the inner electronics to be built as close as possible to the original design intent.

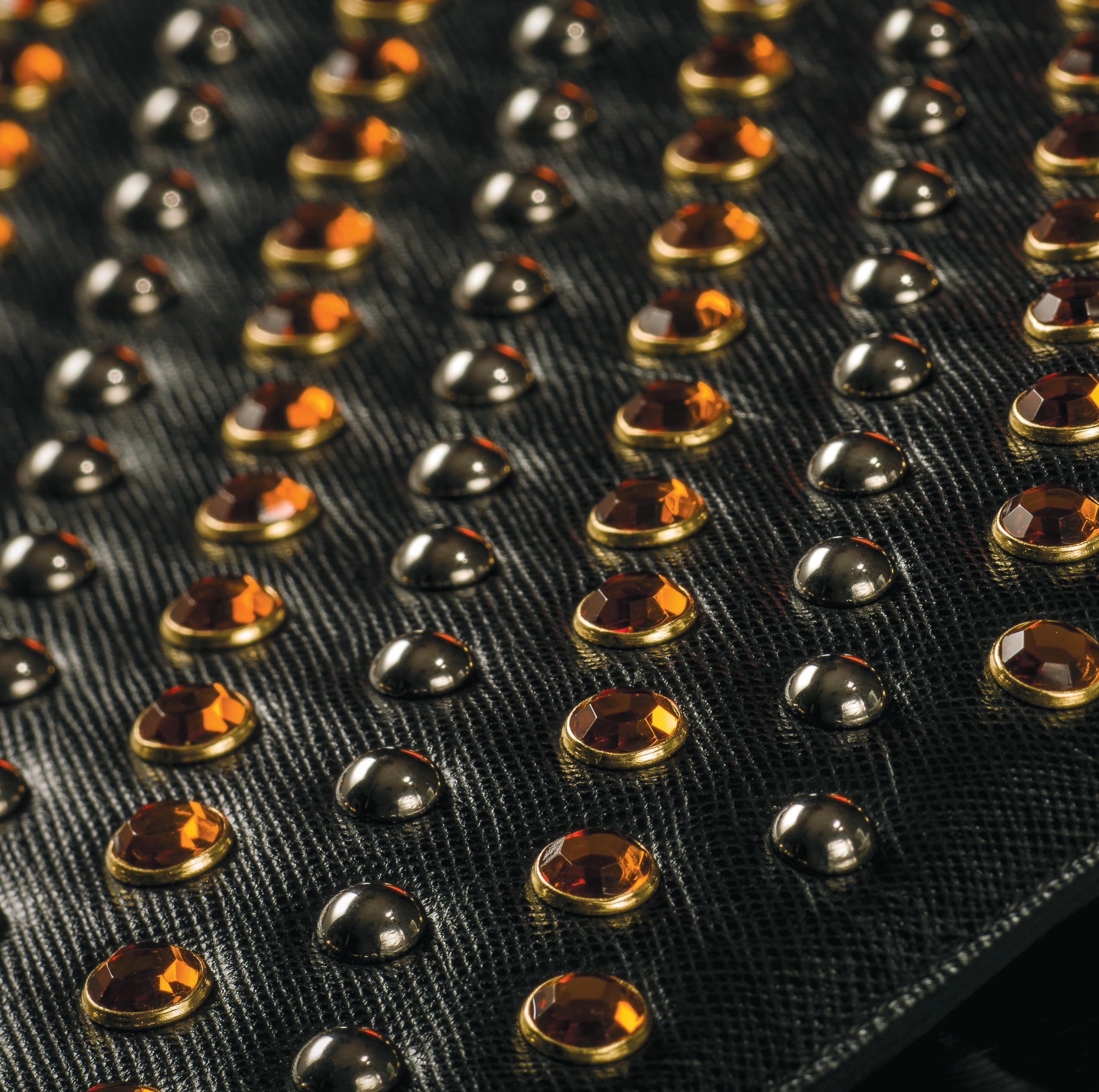

COLOURS AND TEXTURES

Colour and finish were extremely important in creating a design for the PX range that could either seamlessly blend into the background, or stand out as a focal point, depending on the preference of the customer.

“Once the shape is decided to some extent, the general flow is to examine the colours and textures with CG sketches,” explains Casio mechanism development engineer Takahiro Moriya.

The polished finish on the ‘Harmonious Mustard’ coloured model – a radical departure from traditional black-and-white finishes – uses the same high-gloss method as an acoustic piano, with its lustre attained from multiple applications of paint and polishing.

“To express the ideal colour directed by our designer, we went through a number of trials right up until we started mass production,” explains Moriya, adding that this special colour, rarely found on a piano, was chosen for its ability to harmonise with virtually any room’s interior, while adding a touch of elegance to the living space.

To help maintain the analogue form of a piece of furniture, while boasting all the digital capabilities required for a professional-quality instrument, the design team used ‘stealth printing’ for the console area.

“Our intention was that it’s best that the button seems like it doesn’t exist on the console when the LED is off, as it may give a gadget-like impression if any of the letters can be seen through while we want it to look like an interior piece,” says Moriya. With this method, the musician is able

28 DECEMBER 2022 / JANUARY 2023 DEVELOP3D.COM

1 2

‘‘ We created four types of concept model in two batches before the final product design stage, since the new Privia series targets new users ’’

● 1 After conducting initial research in London, the Tokyobased design team headed home to begin its concepting process

● 2 CMF took centre stage for this piano, as Casio strove to create a product that would harmonise with modern home interiors

● 3 Pen-on-paper sketching proved valuable in the process of creating the new design

● 4 Foam prototypes enabled the design team to quickly ideate on scale and angles

● 5 Marketing renders were created to virtually showcase the depth of colours, materials and feel of the product

to see touch buttons when the device is in use, but only a satisfyingly smooth surface when it is turned off.

A key element throughout the development was the use of physical prototypes to further evolve the design. This included initial foam concept models, to evaluate the size and form of the keyboard, and fitting internal electrics into a 3D-printed prototype casing to test sound and playability. Physical prototypes were also used to determine the final production moulds, to confirm consistency between CAE evaluation and actual product, and highlight any issues that might be difficult to determine under CAE evaluation.

The digital work continued with Casio working alongside a regular production partner to create the marketing visualisation artwork from CAD data. “They have captured our intention very well of how the product should be portrayed, so that the users can feel the colour and texture of the product,” concludes Moriya.

With its compact profile, minimalist mid-century aesthetics and high-end finish, the new additions to the Privia PX range have been designed to appeal to a wide range of musicians, enabling them to hit all the right notes. www.casio.co.uk

3 4 5

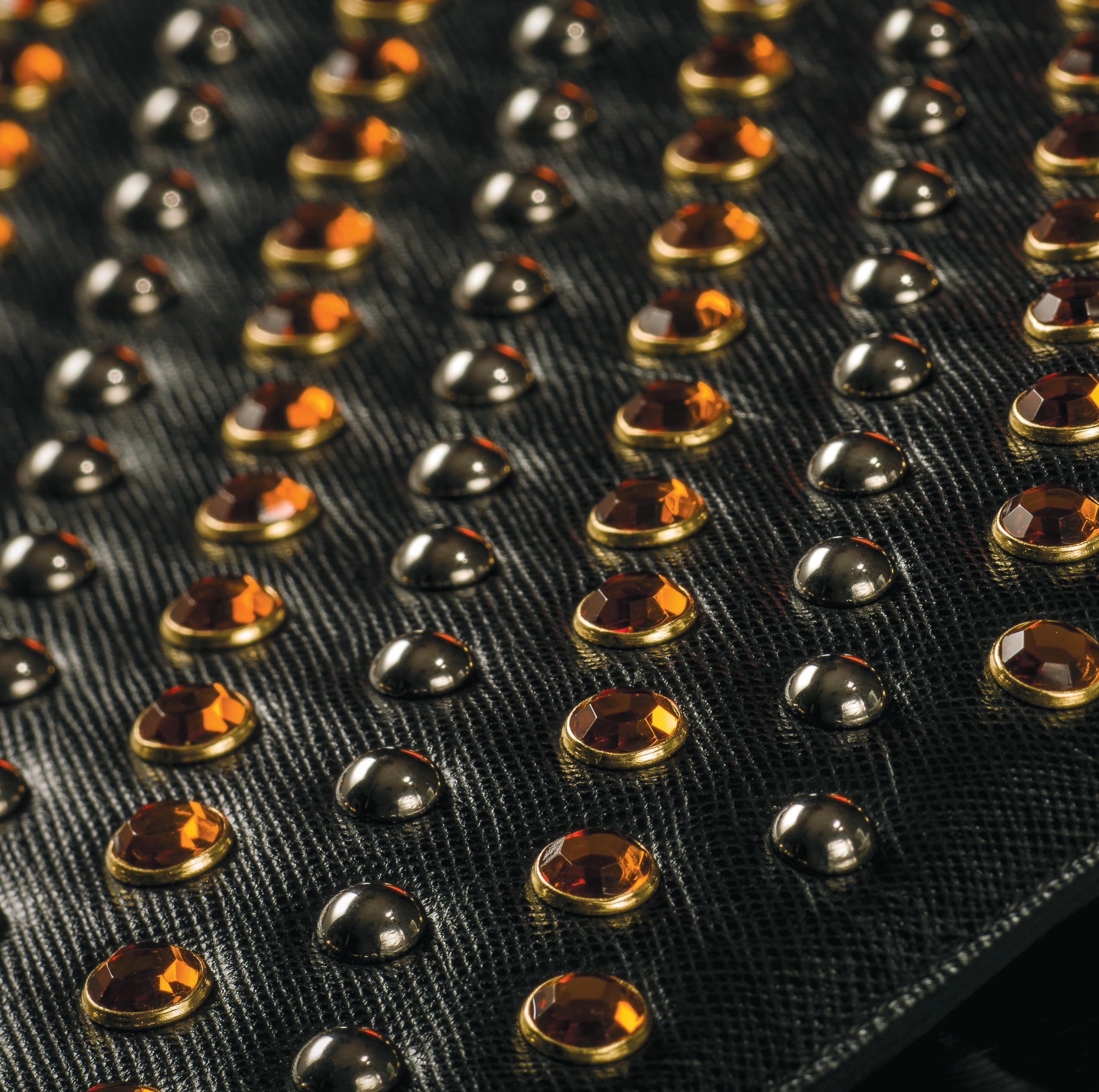

The devil is in the details. In the fashion world, the interior finish of a dress or the design of a tiny button can transform an everyday garment into one that exudes high quality and luxury.

Headquartered in Padua, northern Italy, Eurominuterie produces billions of stamped small metal details for the fashion industry each year. Its output includes decorative elements, internal components, buttons, eyelets, rivets, rollers, hooks and lace feeders for footwear.

Although these components are generally small and simple, they are the result of a careful design study and a production process that involves several stages.

The process starts with a client request, typically for a new or customised design. Team members from the production department at Eurominuterie studies the

30 DECEMBER 2022 / JANUARY 2023 DEVELOP3D.COM

Buttons, eyelets and rivets are just some of the detailed metal parts designed and manufactured for the fashion industry by Eurominuterie. Claudia Schergna spoke to the team to find out how digital tools help deliver those final flourishes for a garment

ONTHEBUTTON

brief and draws on the company’s catalogue, where they can find years’ worth of designs for previous projects. They then make the necessary changes and add some new elements, to come up with something as similar as possible to the item requested by the client in terms of functionality and style. And finally, they work with the technical department to select the best technologies and materials to realise the project.

With over four decades in the industry, Eurominuterie is able to offer a wide choice of processing to enhance a finished product, while also helping guide clients with creative solutions for customisation, says CEO Alessandro Rigato.

For example, he says, “we have developed a refined painting technique that allows the items to maintain strength and aesthetic appearance without giving rise to oxidation or staining.”

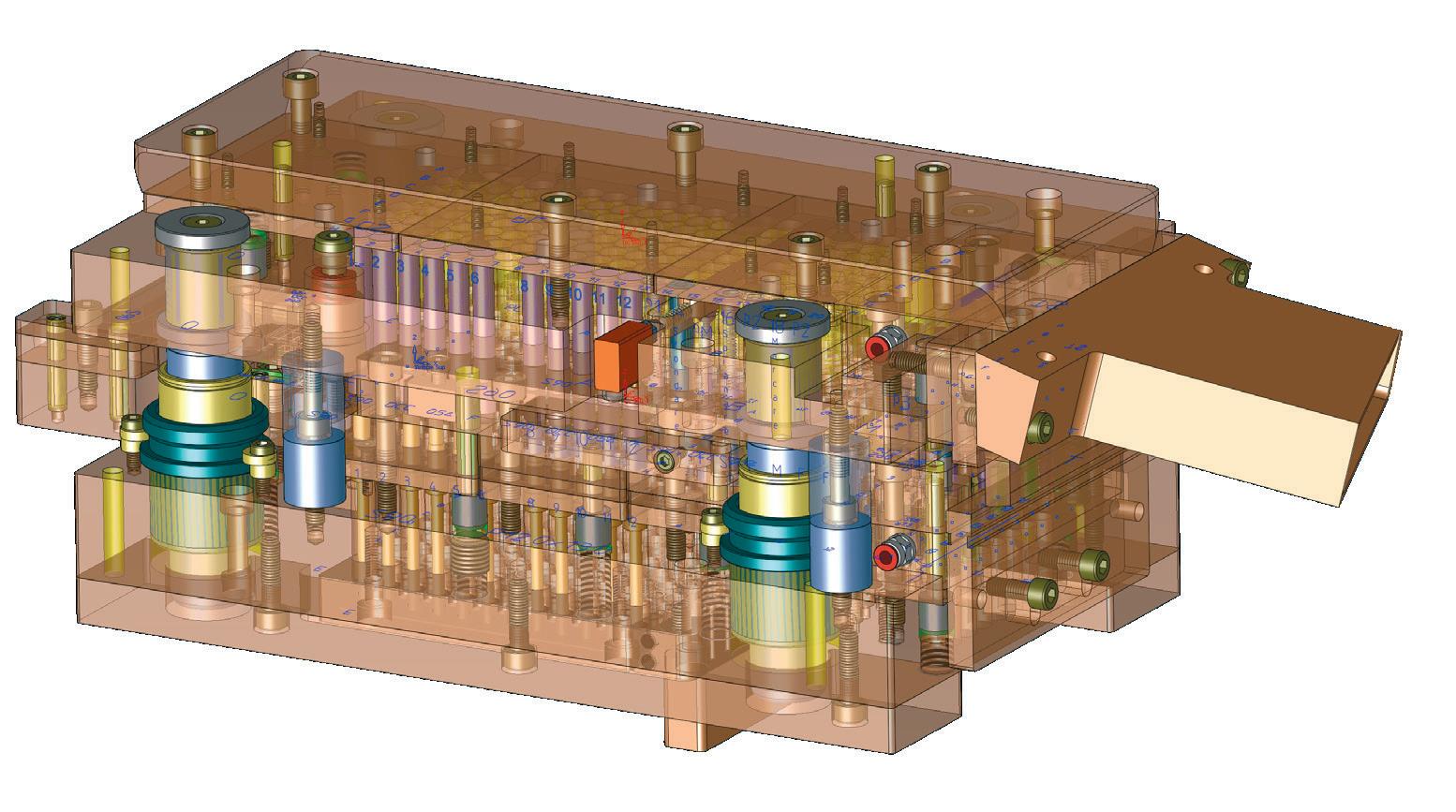

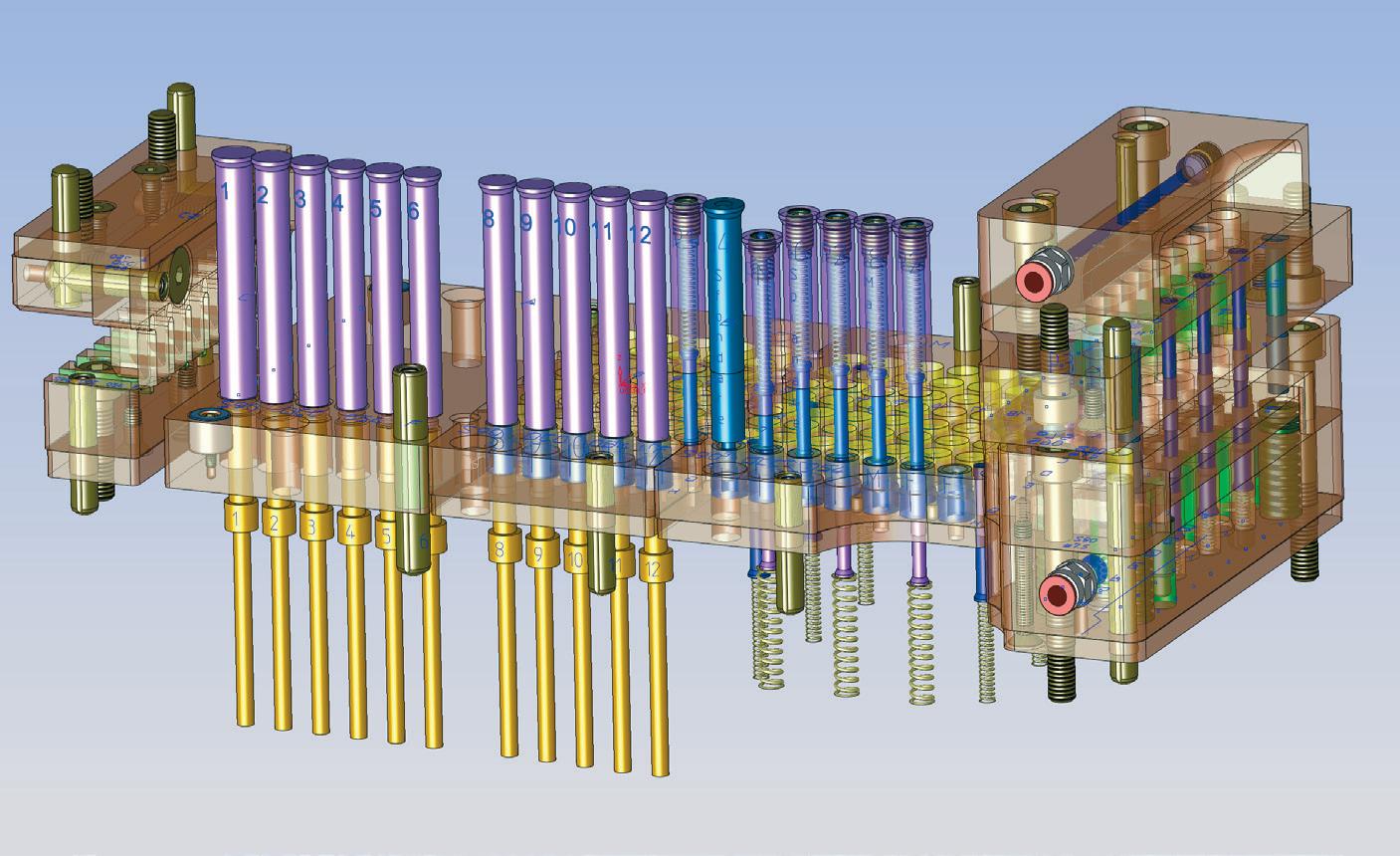

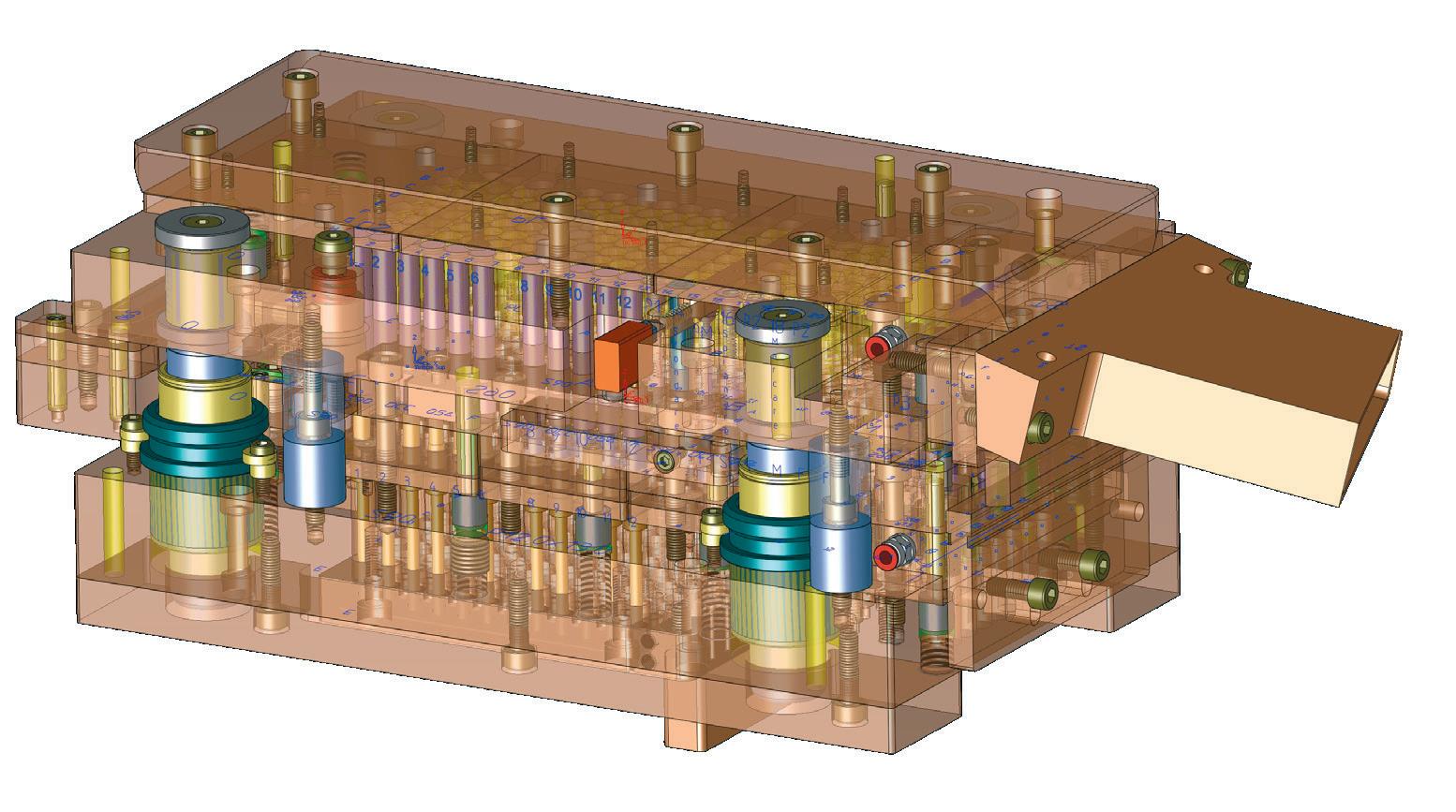

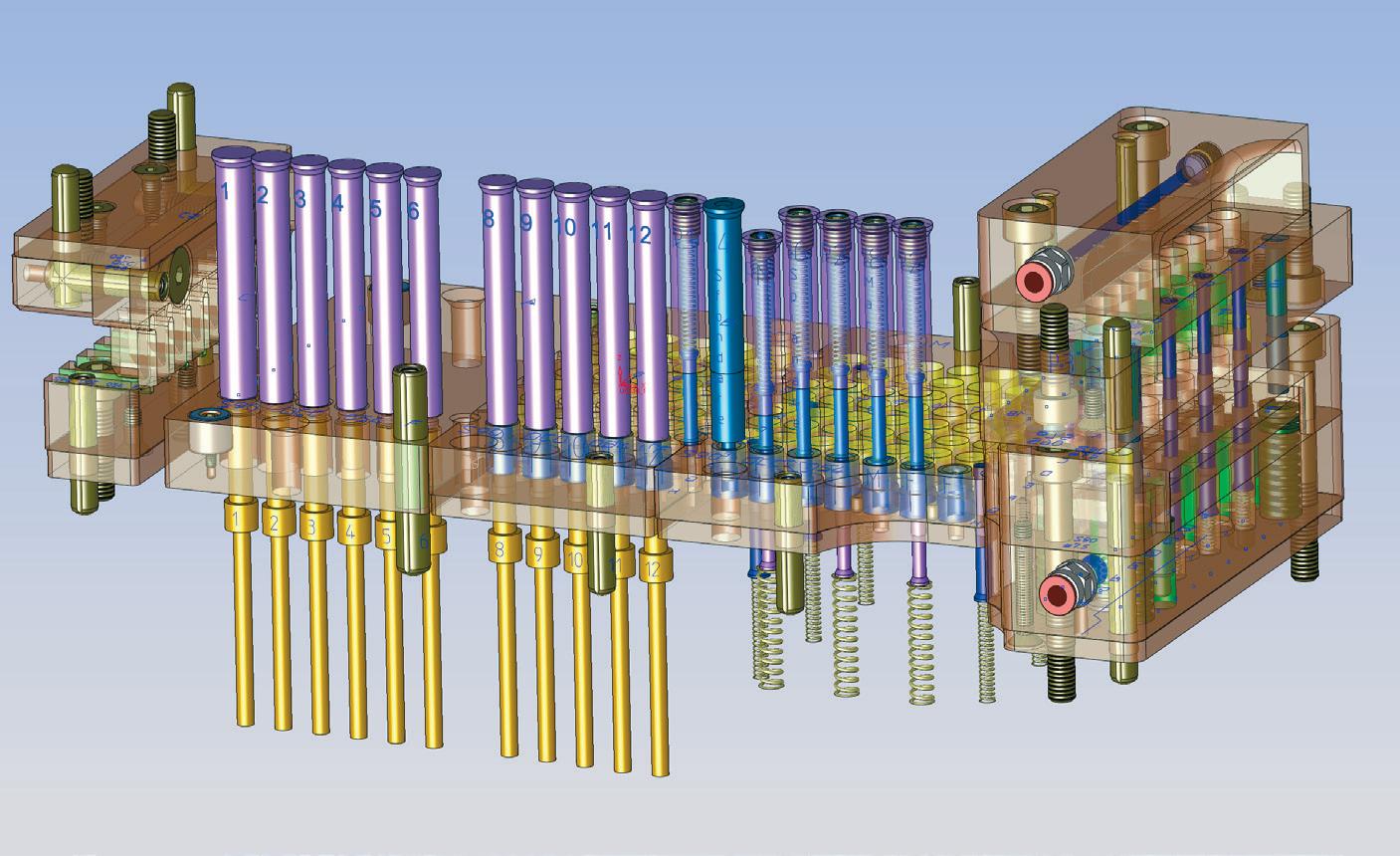

IN-HOUSE MOULDS

As well as producing individual components, Eurominuterie also makes its own moulds in-house, giving it the flexibility to respond to customisation requests, while also reducing production costs, material waste and delivery times.

Moulds for each component are designed using Cambrio Cimatron, which allows the team to visualise the piece and estimate the quantity and cost of material needed. The pieces are stamped on sheets of metal using CNC machines, which are also programmed using Cimatron technology.

Stamped parts then undergo a galvanic process to apply aesthetic and protective treatments by adding a thin layer of metal deposited by electrolysis onto surfaces. These can be more valuable metals like gold, silver, or nickel, giving the product the lustrous finishes desired by the client.

DEVELOP3D.COM DECEMBER 2022 / JANUARY 2023 31

Technology from Cimatron enables Eurominuterie to create fashion details with passion

PARAMETRIC DESIGN

Eurominuterie’s digitalisation process began when the engineering team felt the need for CAM software to help programme its growing number of CNC machines. Once they saw how much the adoption of such technologies aided workflow and how it revolutionised production, they never went back.

Cimatron was chosen in part because of its capabilities with parametric design, explains Rigato, “a method that does not focus on individual results but describes the entire design process, allowing us to automatically, or almost automatically, infer many design variations, promising to increase our competitiveness and profitability.”

The ability to reuse data and develop it further from project to project enables changes to be made with greater ease, he says. Cimatron offers several modellingto-analysis functions that help speed up delivery times and cut costs.

One of these is mould set-up, which allows the team to create 80% or more of the mould. Beyond that, only a few new parameters need to be entered to create a unique custom design.

“Over time, we have set up several basic mould structures in the company: those that are not needed in a new project are simply deleted, then we only need to modify other parts,” explains Rigato.

“The work is completed really quickly. In cutting and punching, the tools in the system from the earliest versions were already very advanced. Now, with the updates and upgrades that Cimatron regularly provides, even the deep-drawing strips can be designed very quickly and reliably. They have given us great advantages in these phases.”

Thanks to this feature, every change is updated in the drawing and all CAM procedures involved. In this way, the parallel design capability enables Eurominuterie engineers to start working on CAM programming even if a design process is just at the beginning stages.

RIGOUROUS, LOGICAL AND INTUITIVE

Rigato points out that the team has developed its own control model for the designs, with a scheme to follow that is available to all technicians, which improves the quality and reduces errors substantially.

The system makes it possible to define precise rules according to a chosen operating standard with which everyone can comply. This might include positions, diameters, rank, applied technologies and tool combinations, for example.

“In reality, the correct way to proceed is dictated by the system itself; the sequence of operations is rigorous, logical and intuitive,” says Rigato. “After constructing our reference formulas, the mould almost assembles itself.”

When it comes to CAM, although the steps at Eurominuterie are not particularly complex, the integration that Cimatron provides between design and machine tool

programming makes the workflow smoother.

“The technology in our industry has not changed much on the method,” says Rigato, “but the way we build today allows us to save literally hundreds and hundreds of hours, not to mention labour. We could never go back from digitisation.”

The digitisation of the product development through manufacture has given Eurominuterie’s team more design freedom to deliver truly unique pieces, each of them capable of catching the eye. www.eurominuterie.com

● 1 After modelling and stamping, the process moves on to the milling of components

● 2 Cimatron Die allows the team to visualise pieces such as eyelets and estimate the quantity and cost of material in advance

● 3 Users can construct the geometry of the mould and utilise that knowledge at subsequent stages in the design process

32 DECEMBER 2022 / JANUARY 2023

PROFILE

1 3 2

WINTER SALE up to 40% Off replik8.co.uk Prices are subject to the items being in UK stock. Stock is limited for some materials. All filament is 1.75mm diameter. Discount is off the current published price or the manufacturers list price. Sale ends on 31st January 2023. Payment is via credit card, paid online. VAT & shipping is added in the checkout. 3D PRINTER FILAMENT

CLICK AND

Born from a young couple’s desire to democratise additive manufacturing, Makelab is a 3D printing bureau like no other. Makelab CEO and co-founder Christina Perla talks to Claudia Schergna about the company’s values and vision

‘‘

Makelab is a different concept. We try to attract creative souls, which is a niche. I don’t think many people in the industry do that

Upload. Print. Collect. That’s how most print shops work today. What if 3D printing could be just as straightforward?

This is the mission behind the 3D printing service bureau Makelab. Based in Downtown Brooklyn, New York, Makelab is very unlike your typical printing facility. Small, bright and spotlessly clean, desktop 3D printers and post-processing machines are arranged neatly on shelves around the lab. A small dog wanders around the office, while the staff chat over their lunch.

“Makelab is a different concept,” says Christina Perla, confidently. The Makelab CEO met Manny Mota, her co-founder, at Pratt Institute, where she was an industrial design student, and he was working as a shop technician. When they first approached the additive manufacturing (AM) industry, they quickly realised that most services were inaccessible for small businesses, freelancers and students.

Some years later, having established themselves in the industry, they came to recognise that the gap in the market that they had spotted as students was actually more like an abyss.

PROFILE

’’ 1 4

AND COLLECT

A MODERN APPROACH

Repeatability and profitability are the pillars on which the Makelab business was built, Perla explains. Local service, an open-door policy and face-to-face contact are what attracts customers and “makes them stick”, she says.

The relationship with customers, meanwhile, is always post-order: “We are not a consultancy,” she clarifies. “Most of our orders come from direct print online.”

An analogy that works with investors, she says, is to position Makelab as an AM version of the Kinko’s chain of copy shops, now part of FedEx. While there are clear differences, she adds, “it really explains the multilocation play that we’re going for, the hyperlocal presence and the culture we have here.”

Another similarity is that, for Makelab, no order is too small. Most customers will submit an order quantity of one at first, because it involves the lowest risk. Once they have the results in their hands, they frequently go on to order larger quantities.

Makelab’s most recent projects range from kitchen tools to supports for card games, from jewellery to packaging, and from fem-tech to art installations.

Having such a wide customer pool can be a doubleedged sword. On one hand, it brings more business opportunities. On the other, it might lead to scepticism,

given that other bureaus often specialise in serving a single industry. “The risk is that we might look unfocused,” says Perla.

“We try to attract creative souls, which is a niche. I don’t think many people in the industry do that.”