EDITOR´S COMMENTS

INDUSTRY NEWS

GREENHOUSES AND POND LINERS

The future of intensive tilapia production and the circular bioeconomy without effluents: Biofloc technology, recirculation aquaculture systems, bio-RAS, partitioned aquaculture systems and integrated multitrophic aquaculture.

Editor and Publisher Salvador Meza info@dpinternationalinc.com

Contributing Editor Marco Linné Unzueta

Indonesia towards a world aquaculture giant.

A bioeconomic model for the evaluation of a backyard aquaculture system for tilapia (Oreochromis niloticus).

Editorial Coordinator Karelys Osta edicion@dpinternationalinc.com

Editorial Design Perla Neri design@design-publications.com

Sales & Marketing Coordinator crm@dpinternationalinc.com

Sales Support Expert sse@dpinternationalinc.com

Operations Coordination Johana Freire opm@dpinternationalinc.com

Business Operations Manager Adriana Zayas administracion@design-publications.com

Subscriptions: iwantasubscription@dpinternationalinc.com

Design Publications International Inc. 401 E Sonterra Blvd. Sté. 375 San Antonio, TX. 78258 info@dpintertnatinonalinc.com

Office: +210 5043642

Office in Mexico: (+52) (33) 8000 0578 - Ext: 8578

Aquaculture Magazine (ISSN 0199-1388) is published bimontly, by Design Publications International Inc. All rights reserved. www.aquaculturemag.com

Follow us:

UPCOMING EVENTS

ADVERTISERS INDEX

» 2 APRIL - MAY 2023 on the cover

INDEX Aquaculture Magazine Volume 49 Number 2 April - May 2023 Volume 49 Number 2 April - May 2023

From

a cell model

to

a fish trial: Immunomodulatory effects of heat-killed Lactiplantibacillus plantarum as a functional ingredient in aquafeeds for salmonids

6 4 12 18

28 54

ARTICLE ARTICLE

22

32 40 42

FAO IN AQUACULTURE

Half of my professional life working for FAO.

By Alejandro Flores

34

THE RECIRCULATOR

Some thoughts/observations on the current state of RAS technology as a viable alternative for aquaculture production.

By Philip Buike

By Philip Buike

46

CARPE DIEM

Branding, branding, branding…

By Antonio Garza de Yta, Ph.D.*

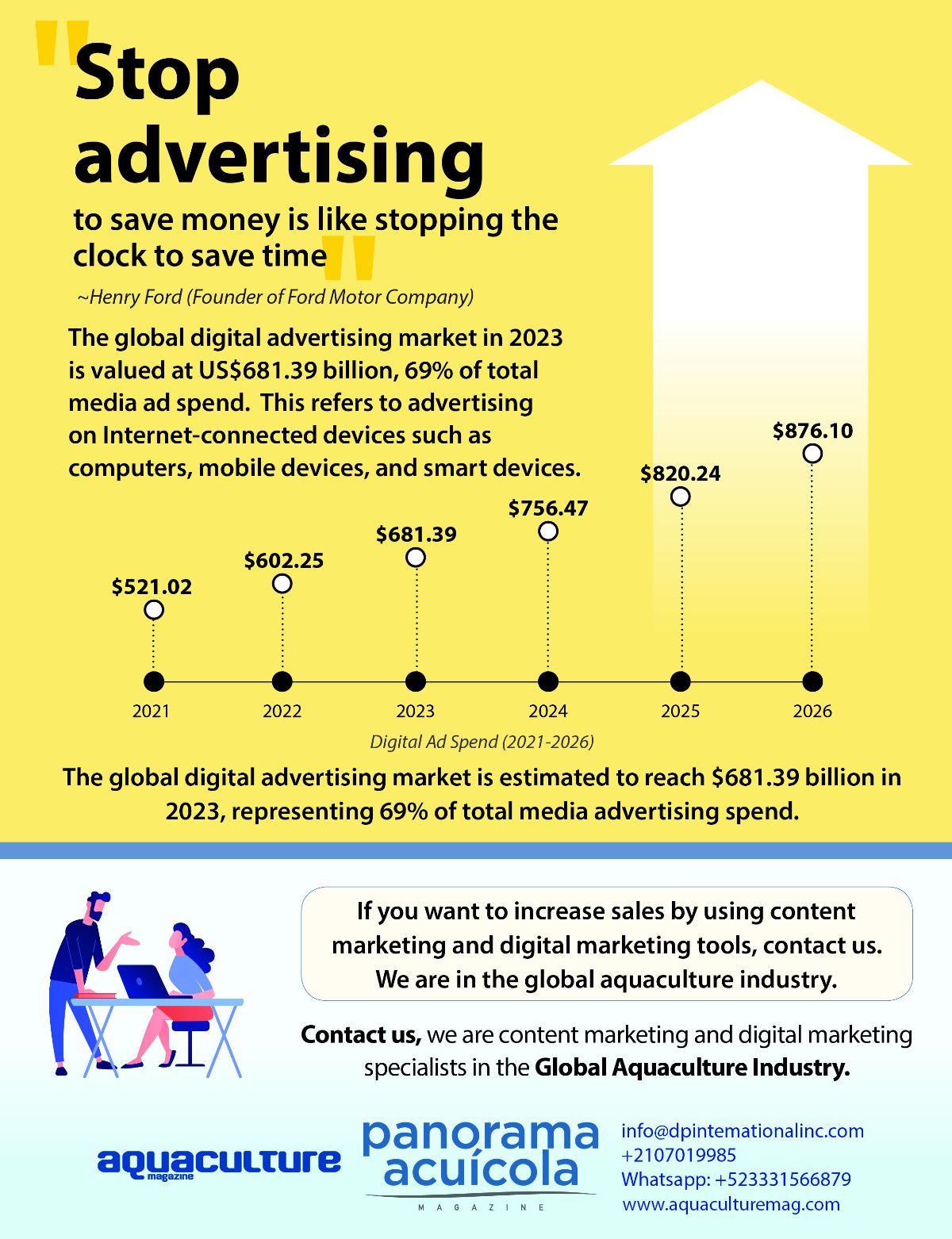

DIGITAL AND SOCIAL MARKETING BYTES

Cybersecurity basics for protecting your business online.

By Sarah Cornelisse*

THE GOOD, THE BAD AND THE UGLY

Why growing bacteria up pond side without professional oversight may be a biosecurity nightmare?

By Stephen G. Newman Ph.D. * President and CEO AquaInTech Inc.

By Stephen G. Newman Ph.D. * President and CEO AquaInTech Inc.

50 THE FISHMONGER We can do better.

» 3 APRIL - MAY 2023

COLUMNS

Marco Linné Unzueta Associate Editor

The aquaculture-fisheries sector encompasses the set of activities that originate in the use of aquatic flora and fauna resources, especially the capture and cultivation of these resources, their transformation and commercialization. It is part of the economic activity of a country or region with an extractiveproductive approach, and is of vital importance in the generation of food of high nutritional value, employment and economic income for the population, as well as a source of input for the food industry and foreign exchange for the country.

Based on the opening up of trade in food products at the international level and the signing of agreements in this area, the health authorities of the countries have made it a priority to establish policies to ensure the health and safety of food and its access to national and international markets. At the global level, two factors have had a direct impact on the relevance and use of the concept of “animal health”: a) the risk to the public health generated by con-

Aquaculture health and safety: tools for traceability in aquaculture products

suming spoiled products, and b) the premise of being responsible for environmental contamination.

As a result of the above, health and safety has become an important asset for countries to participate in agri-food trade, so they are stricter in controlling pests and diseases in accordance with policies aimed at preserving wildlife and animal health and in order to ensure the quality and safety of food for the population. For this reason, product exporting countries must invest in an increasingly rigorous control system in which health, quality, and food safety become the cornerstones of international trade. One of the fastest growing international food production systems in the last three decades has been aquaculture, which, as a result of having diversified, intensified and modernized very rapidly, contributes to food production, foreign exchange generation and food security; however, its products must be regulated by international health and safety agencies.

At the international level, countries have included health and safety

as part of their food safety policies, both because of the global trend and to ensure and increase the domestic and export marketing of their products. In view of the above, and the fact that aquaculture health and safety are priorities as strategies to ensure and increase the availability of food products, both for domestic marketing and export, it is considered necessary for producers to interact with research institutions dedicated to generating relevant information on these issues. By being updated, they will be able to face the new market scenarios.

This interaction is generated in forums such as the Aquaculture Health and Safety Forum, where the results of relevant research are presented. Given the relevance of the aspects that allow sustainable production, the sanitary and safety aspects in the production of aquatic species should be considered, and management strategies to minimize or eradicate the effects caused by diseases or parasites typical of the cultivation of aquatic organisms.

» 4 APRIL - MAY 2023

Sea Bream Farm is Japan’s First Facility to be Best Aquaculture Practices (BAP) Certified

The Ainan Fishery Cooperative Association, which produces red sea bream, has become the first facility in Japan to achieve Best Aquaculture Practices (BAP) certification, the Global Seafood Alliance (GSA) announced. Located in Ehime Prefecture, Japan, the Yasutaka Suisan farm and the Hamasui processing plant, both members of the Ainan Fisheries Cooperative, have achieved BAP certification.

“We are very pleased that two of our members, Yasutaka Suisan and Hamasui, have become the first in the world to receive BAP certification for red sea bream. BAP standards have been benchmarked by the Global Sustainable Seafood Initiative (GSSI) at the farm, and the Global Food Safety Initiative (GFSI) at the processing plant, which we believe will give further impetus to exports,” said Hiroki Tachibana, President of the Ainan Fishery Cooperative Association.

“Although Ainan is a small town at the southernmost tip of Ehime Prefecture, it is one of Japan’s top aquaculture producers, and we hope that Ainan sea bream will spread its wings to the rest of the world,” he added.

“The seafood industry in Japan is among the leaders in Asia for promoting and developing more responsible practices that fit with the United Nations Sustainable Development Goals. I would like to commend the Ainan Fishery Cooperative Association for becoming the first BAP-certified facility in Japan, with their red seabream farm,” assured Steve Hart, VP of Market Development at GSA.

Third-party certification

It’s good to remember that Best Aquaculture Practices is a third-party certification program developed by the Global Seafood Alliance, an international, nonprofit trade association headquartered in Portsmouth, N.H.,

USA, dedicated to advancing environmentally and socially responsible seafood practices through education, advocacy and third-party assurances. Through the development of its Best Aquaculture Practices and Best Seafood Practices certification standards, GSA has become the leading standards-setting organization for seafood.

“When creating our BAP and BSP standards, we think about the fact that broad guidelines may cause unintended consequences given the complexities of seafood, which can differ greatly by species, production method and region. Our Standards Oversight Committee (SOC) and technical committees work tirelessly to ensure the seafood industry rises to the highest level of animal welfare, food safety, social accountability and environmental stewardship,” they said.

BAP standards address the most pressing issues when it comes to aquaculture. Certified facilities must meet every single line in our standard to achieve certification, with no exceptions. Other certification schemes allow for non-conformities, but BAP does not in order to ensure responsible practices at certified facilities.

“Our process allows for transpar-

ency and collaboration at every step of the process, and we invite public comments when standards are in the process of being developed or refined. Our standards exist to enable our vision of a world that embraces the role of responsible seafood in meeting global nutrition needs.”

Among other things, BAP standards require farmers to set upper limits for fasting periods. These periods are needed prior to harvest to aid food safety and ensure the quality of finished products. Also, BAP standards require that fish be slaughtered humanely. Adapting specific humane slaughter methods for each aquaculture species is an avenue that must be explored by farmers.

The Global Seafood Alliance has been fully committed to promoting best practices in animal health and welfare through the extensive adoption of its Best Aquaculture Practices (BAP) certification standards for 20 years now, and will continue to refine them for many years into the future.

The GSA has been fully committed to promoting best practices in animal health and welfare through the extensive adoption of its Best Aquaculture Practices certification standards for 20 years now.

» 6 APRIL - MAY 2023 INDUSTRY NEWS

ASC and SFP join forces to enhance responsible aquaculture production worldwide

The Aquaculture Stewardship Council (ASC) and Sustainable Fisheries Partnership (SFP) signed a Memorandum of Understanding (MoU) formalizing their common goal of increasing the sustainability of aquaculture production and practices around the globe. The signature was made on April 25 at Barcelona’s Seafood Expo Global. The ASC and SFP are currently building a work plan for the next steps of the collaboration. The MoU builds on work by the ASC and SFP on data sharing and aligning information systems.

“We are excited to explore new ways of collaborating with SFP whit whom we had a longstanding and successful history of partnership for many years. By working together on scaling our efforts in the aquaculture improvement space, enhancing the sustainability of the reduction fisheries sector based on ASC Feed Standard requirements and coordinating our market engagement efforts, we aim to leverage our shared work with farmers, feed suppliers and other stakeholders,” said Chris Ninnes, ASC CEO. “Our collaboration is a powerful opportunity to increase sustainable aquaculture production,” said SFP founder and CEO, Jim Cannon. “With the ASC, we can innovate and enhance the scope of aquaculture improvement projects so that more producers can improve practices, more government regulators can strengthen governance, and more buyers can find meaningful ways to engage and support improvements.”

Complementary approaches

ASC promotes responsible seafood farming by setting the standard for seafood farmed with care and operating a third-party certification model at farm level. Producers are checked on-site by for compliance with the ASC standard and can use the ASC label if they pass the audit. SFP maintains FishSource with aquaculture management status

assessments to monitor and improve the sustainability of farmed seafood production at the landscape scale. They believe that these complementary approaches can deliver more impact througth collaboration and combination.

A key project in the works is ASC’s Improver Program to help producers who cannot currently achieve certification improve their farming practices and performance and reach a level that meets certification requirements. ASC and SFP plan to develop a process for designating stepwise improvements across at least four impact area modules (water quality, disease management, feed and effluent). Together, the organizations will also look into developing a framework to monitor and track progress.

More projects

ASC and SFP also intend to work together on increasing sustainability and reducing the ecological footprint of aquaculture feed ingredients and production. In collaboration with a broader suite of partners, the ASC and SFP aim to deliver an improvement framework for South American fisheries based on ASC Feed Standard requirements and aligned to the goals of the Global Roundtable on Marine Ingredients.

13

years

In 2010 was launched the Aquaculture Stewardship Council (ASC) as an

impact-driven NGO. They partnered with the Dutch Sustainable Trade Initiative IDH and WWF Netherlands to make aquaculture more sustainable. ASC does this by setting strict standards for seafood and farms and delivering high assurance throughout the supply chain.

To drive our third-party certification and labelling program for seafood farming worldwide, we work with the environmental and scientific communities and beyond. Together, they develop standards with other NGOs, academics, farmers, retailers and experts, and they keep developing more standards to meet changing market needs and demand.

ASC certified farms are independently assessed against every requirement in their species-specific ASC standard. Our system has been evaluated against ISEAL’s Codes of Good Practice, a globally-recognized framework for effective, credible sustainability systems. By adheringto these codes, we’ve become the world’s leading farmed seafood certification program, from farm to fork. In the case of SFP, is a United States (US) registered nonprofit that operates globally to rebuild depleted fish stocks and reduce the environmental and social impacts of fishing and fish farming. The organization works by engaging fishery stakeholders and seafood businesses throughout the supply chain to promote the sustainable production of seafood.

» 7 APRIL - MAY 2023

Benchmark promotes Stenerud and Holmvåg in new leading commercial roles to

sustain successful sales growth of the salmon product range

A significant breakthrough in the development of disease-resistant tilapia strains.

Effective May 1, the Norwegian company Benchmark has appointed Kate Furhovden Stenerud as the new Commercial Director for salmon, while Thommy Holmvåg was promoted to the position of Commercial Lead for genetics in Norway. These changes are part of the company’s strategy to enhance its sales of genetics and health products for the aquaculture industry. The sales department is now better equipped to continue the positive growth of Benchmark ’s product range.

Stenerud takes over the commercial responsibility from Geir Olav Melingen, who will become the new Head of Benchmark Genetics starting next June 1. Stenerud previously worked with regional customer responsibility in South Norway and has collaborated closely with the global sales team. In her new role,

she will report to Melingen, who is pleased that Kate has accepted the position.

Melingen states: “Kate has proven to be a strong candidate for this role, and we are delighted to have her take on this new responsibility. Her contribution will continue the great work that has been done in genetics and health for salmon worldwide.”

Benchmark ’s commercial teams for Atlantic salmon are located in Norway, the UK, Iceland, North America, and Chile, and the company provides fertilized salmon eggs and delousing services to more than 40 countries worldwide.

Holistically organized on sales and marketing

To support Stenerud in her new role, Thommy Holmvåg has been ap -

pointed as the Commercial Lead for genetics in Norway, a newly created position, and will report directly to her. Holmvåg previously held the responsibility of managing regional customers in Northern Norway.

“Thommy is a dynamic and collaborative team player who effectively communicates with both our customers and the team. These strengths will help us further develop our work both internally and externally,” commented Stenerud.

The commercial team and genetics marketing department were reorganized in June 2022 to focus more holistically on sales and marketing of the company’s Atlantic salmonrelated products. This restructuring has positively contributed to building even stronger customer relationships and improving collaboration across different departments.

» 8 APRIL - MAY 2023 INDUSTRY NEWS

Tilapia strains: a significant step

On the other hand, the company’s team of scientists has identified a significant quantitative trait locus (QTL) affecting resistance to Streptococcus iniae in Tilapia, a significant step towards improving the health and sustainability of Tilapia farming.

Recent research demonstrates a significant quantitative trait locus (QTL) affecting resistance to Streptococcus iniae in Benchmark Genetics’ high performing strain of Nile tilapia. This discovery is the result of an award-winning collaboration between the USDA’s Aquatic Animal Health Research Unit (AAHRU) and Benchmark ’s geneticist Sergio Vela-Avitúa et al.

The QTL found by the team explained up to 26% of the genetic variation in resistance. Fish were then selectively bred for survival to S. iniae using marker-assisted selection (MAS) to demonstrate resistance in fish classified as “resistant” or “susceptible”.

The results were impressive, with a final cumulative percent mortality of only 1% for offspring from resistant parents, compared to 73% for offspring from susceptible parents. These results demonstrate that MAS for improved resistance to S. iniae is feasible and likely to be highly effective.

Benchmark Genetics has already implemented these results into their breeding and production of genetically improved Spring Tilapia breeders and fingerlings.

In that sense, Morten Rye, Director of Genetics at Benchmark Genetics commented: “We are thrilled to announce this breakthrough in the development of more disease-resistant tilapia strains. Our proprietary Spring Tilapia strain is the result of years of pioneering research and innovation, and we are committed to using our expertise to improve the sustainability and profitability of the global tilapia industry. We are confident that this new development will provide significant benefits to our customers and to the industry as a whole.”

» 9 APRIL - MAY 2023

Long-term contract with the global leader in aquafeed Skretting signed

The Norwegian company Nordic Halibut has signed a three-year contract with Skretting as a halibut feed supplier. The agreed collaboration ensures stability and predictability for feed supply to cover the company’s growth plan phase 1 of 4,500 tonnes HOG production in 2026. The company has worked closely with Skretting over several years to develop sustainable products with precise nutrition that are specialized for halibut, and now the two companies are currently working on the next generation of halibut feed.

“We believe that long-term cooperation is fundamental to achieving sustainable development. Working closely with Skretting will help us optimize the feed so that we can offer a premium quality product with a minimal footprint. Their ambitions in terms of quality and sustainability reflect ours, and therefore we choose to enter a new three-year partnership that ensures sufficient high-quality feed supply towards our production targets in 2026,” said CEO Edvard Henden.

On the other hand, Martin Davidsen, sales manager at Skretting Norway, assured: “We at Skretting are very happy for this long-term collaboration with Nordic Halibut. We have extensive experience with halibut feed, and now we will use our nutritional knowledge together with our extensive efforts for sustainability so that we can develop tomorrow’s halibut feed to be even more sustainable.”

Optimize the feed

Nordic Halibut strives to sustain a high level of performance in the company’s ESG areas and to establish ambitious ESG targets to maintain sustainable production and uplift local communities.

For them, it is advantageous that the Skretting production facility is located at Averøy, near Nordic Halibut’s core production hub at Nordmøre contributing to minimizing supply risk and reducing

the environmental impact of transportation.

Nordic Halibut is the brand name for exclusive, fresh Atlantic Halibut (Hippoglossus hippoglossus) on ice, but it is also the name of the company that produces it. According to them, Nordic Halibut believes in aquaculture that is responsible and secures a future for many generations to come.

“Our desire is to have a positive impact on the environment, local communities, and the health and culinary choices of our customers. Our passion is to raise fish that bring variety to dinner tables with a focus on fish welfare and sustainability. Our vision is to provide our customers with superior quality halibut through constant innovation and research,” they said.

Nordic Halibut is based on the west coast of Norway and has five departments stretching from Bergen to the island of Averøya. “We have full control of our production line from roe to fish of harvestable size. Our halibut is available fresh on ice all year round and does not depend on seasonal changes,” they added.

Achieves Global GAP certification

Recently, Nordic Halibut has reached a milestone in the company’s ambition to offer sustainable superfood with certification according to the Global GAP Aquaculture Standard now secured, which covers the entire production val-

ue chain from broodstock and juveniles to farming and harvesting.

The audit, performed by Kolos Aqua, assured the Company’s compliance with strict criteria for food safety, animal health and welfare, environmental sustainability and biodiversity, workers’ well-being, production processes, legal compliance, and traceability.

NOHAL also underwent the Global GAP Risk Assessment on Social Practice (GRASP), a part of the certification process applied to assess social risks in primary production and to provide additional transparency to supply chain partners.

“We are very pleased to have obtained this certification. It demonstrates our commitment and operational focus on sustainable halibut farming. The certification ensures that the Company’s production meets all international requirements for food safety, sustainability and welfare for both fish and employees throughout the value chain,” said Henden when the news was released.

Henden added that the certification reflects NOHAL’s ambition to produce sustainable, healthy protein in an industrial scale. NOHAL will be a sustainable producer contributing to a blue future with product quality and fish welfare as key parts of the Company’s ambition to produce 4,500 tonnes HOG within 2026 and 9,000 tonnes HOG within 2030.

» 10 APRIL - MAY 2023 INDUSTRY NEWS

Probotic secures a patent for an autonomous fish farm cleaning system

Probotic, a leading developer of autonomous underwater technology, announces the successful acquisition of a patent for its innovative cleaning system for fish farms. The patent covers marine and land-based fish farms. It represents a significant milestone for the company, which has been working tirelessly to create a system that efficiently cleans fish pens autonomously while minimizing damage to the pens and fish.

According to Mikkel Pedersen, CEO of Probotic, “We are thrilled to have received this new patent in Norway. It is a testament to our team’s hard work and dedication and a major step forward in our efforts to revolutionize the aquaculture industry. This patent is just the beginning for Probotic, and we have many more exciting developments and news in the pipeline.”

Probotic’s innovative system combines advanced robotics and artificial intelligence to clean fish pens autonomously and efficiently. The company has conducted real-world tests of the system during the last eight months in partnership with Ballangen Sjøfarm. It has made significant improvements to ensure the system can withstand harsh conditions over time.

“We have overcome some of the biggest potential challenges for the system and are now scaling testing to include new fish farmers,” Pedersen added. “We are also preparing for a commercial pilot later this year, which we hope will enable us to bring our technology to the market and revolutionize how we clean and inspect fish pen nets.”

Probotic’s patent marks a significant validation of the company’s technology and positions it well to attract investment and partners to bring its innovative system to market. The company remains committed to developing new solutions that can increase the productivity of fish farms while minimizing their environmental impact.

About Probotic

Probotic is a Norwegian Aquatech company founded in 2019 focusing on sustainable food production. Headquartered in Narvik and Trondheim, Probotic’s first product is an au-

tonomous underwater drone called Probot. This drone uses advanced technologies such as AI, cloud solutions, big data analytics, and machine learning to clean and inspect fish nets, ensuring optimal fish health and growth conditions. Probotic aims to become a leading high-tech brand, partnering with customers who share their vision for a cleaner, more sustainable future.

» 11 APRIL - MAY 2023

The future of intensive tilapia

production and the circular bioeconomy without effluents: Biofloc technology, recirculation aquaculture systems, bio-RAS, partitioned aquaculture systems and integrated multitrophic aquaculture

In recent decades, one of the most important innovations and trends in tilapia culture has been towards a circular bioeconomy, as characterized in this review by several recirculation systems, such as biofloc technology (BFT), recirculation aquaculture systems (RASs), bio-RAS, partitioned aquaculture systems (PASs with split ponds, SPs, and in pond recirculation systems, IPRS) and integrated multitrophic aquaculture (IMTA).

By: Aquaculture Magazine Editorial Team*

By: Aquaculture Magazine Editorial Team*

Resource flow in a circular economy can help reduce the use of increasingly scarce resources, reduce waste production and limit energy consumption. In a world with a growing demand for clean water and healthy food, the economy in a linear model is no longer adequate, since modern societies cannot build a future under a ‘take-do-discard’ model. The movement towards environmentally sustainable systems are necessary through circular and life cycle thinking to preserve our finite natural resources. Water, in particular as a valuable resource, must be treated with respect and managed with methods to reuse and conserve it, putting it into action the concepts of circular bioeconomy.

Circular Bioeconomy without Effluents

The circular economy can be defined as a production strategy that aims to reduce inputs, as well as waste production, close economic and ecological resource flows or links, decentralize production systems (local production and consumption) and question tools for measuring economic performance and the role of money and finance in building natural and social economic capital. The analysis of physical resources flows are of two main types: (1) linear, where biological wastes

(nutrients) are expected to be reintroduced into the biosphere, and (2) circular, with biological wastes (nutrients) being recirculated and used again in the production system, not returning to the biosphere.

Traditional aquaculture generates wastes that are deposited directly into nature, providing high levels of nitrogen and phosphorus to the natural environment. These represent a threat to human health, the welfare of fish and shrimp and the overall environment. The frequent diseases that occur in aquaculture and the growing demand of the population for clean, sustainable aquafarming that is environmentally friendly are leading to the development of alternative production models with greater

and more efficient controls, increase in predictability and repeatability of activities. These include a series of structural changes in aquaculture activity that consider the treatment of water and waste through closed landbased recirculation aquaculture systems (RASs) and the reuse of waste as nutrients. The partial or total reuse of water from aquatic crops has generated a series of land based RAS, undoubtedly the most important innovation in aquaculture in recent decades when integrated with complementary systems forming a donor and receiver system.

Recirculation is based on the movement of water through various compartments, tanks or ponds of different sizes. The water passes from

» 12 APRIL - MAY 2023

GREENHOUSES AND POND LINERS

one compartment to another and is partially or totally reused, depending on the intensity of the culture, ranging from more extensive/semiintensive ponds to intensive/superintensive tanks. The more intensive systems make use of sophisticated biofilters, compartments with biofilters, mechanical filters, geo-membranes/liners and various treatment methods, using any species grown in conventional aquaculture such as fish, crustaceans, molluscs, algae, and so on. Recirculation technology is widely used today in tropical fish farms, primarily for biosecurity reasons. RAS is

showing enormous growth in marine shrimp, bivalve and seaweed farming, especially in the initial phases (hatchery and nursery). There is also enormous investment in recirculating water in salmon farming, but at low temperatures filter microorganisms are not very efficient, which greatly increases the costs of biofilters and additional structures.

Low water demand systems, either in isolated or recirculating compartments with intense aeration and a high load of omnivorous tilapia or shrimp (more than 8 units/m3 for fish and 100 units/m3 for shrimp)

Tilapia tolerates very poor water quality conditions and will survive oxygen depletions that would kill most other fish, so they could be stocked in very small ponds at high densities and still thrive.

end up spontaneously generating bioflocs. In a single compartment, for example, a pond or tank, bioflocs are known as BFT (from biofloc technology). By recirculating the water in more compartments, this system can be called bio-RAS, a combination of the BFTs and the RAS. The primary objective is to improve the biosecurity of crops in places where water is scarce and/or land is expensive since the minimum exchange of water reduces the incidence of diseases. The recirculation and reuse of water is the most classic application of the circular economy in aquaculture. These techniques are deployed in several aquaculture systems with possibilities of ‘zero effluents’ (Figure 1), whose focus is to maintain stable water quality and levels through the recycling of nitrogenous and carbon components, carried out mainly by specific bacteria, which are stimulated by the balance/ratio of carbon and nitrogen (C:N) in the water.

Recirculation Aquaculture Systems

The main objectives of a more extensive recirculation aquaculture system (RAS) in ponds is to conserve water and generate less effluent that could damage the surrounding environment. To achieve this, an increased technology level is needed, which by default increases productivity. Despite the productive and environmental ad-

» 13 APRIL - MAY 2023

vantages, the reuse and maintenance of water quality, especially in more intensive RAS, will depend on a series of structures and equipment that are still relatively expensive, such as: settlers, mechanical filters, biological filters, ultraviolet lamps (disinfection), water pumps, air blowers, power generators, emergency aeration, ozone generation, and so on (Figure 2). In addition to the high investments in building structures and equipment, there are high operating costs such as electricity, maintenance and depreciation. This is in part compensated for by the flexibility to locate production facilities near large markets, complete and convenient harvesting, and quick and efficient disease control. RAS have been widely used for hatcheries and nurseries for both freshwater and marine aquaculture. In recent years, large scale production with RAS for grow-out to harvest size has come into commercial success.

Unfortunately, there were significant number of failures in RAS commercial operations before the more recent successes.

Biofloc Systems

The bioflocs are composed of assemblages of heterotrophic, nitrifying and cyano-bacteria as well as various algae and fungi. Therefore, compared with the more intensive RAS, it does not require filtration structures and can simply consist of tanks and aerators/pumps (Figure 3). The bioflocs in a single compartment (BFT) can be inserted into a recirculation system (optional), with a settler (optional) to control excess solids, a drainage system (optional), a blower and/or water pump and power generators. The structural and operational advantages of a BFT allows cultivation with high loads of suspended solids in the water, characteristics that affect different species produced in the RAS, but do not impact omnivorous filter-feeding species such as tilapia and marine shrimp, two of the most used species in BFTs around the world. The ability to work with a relatively high solids

load makes the BFT less dependent on mechanical filters. It also abolishes the need for either partial water exchange or a secondary denitrification system typical of a highly intensive RAS.

BIO-RAS

Bio-RAS is the combination of RAS with BFT (a recirculation system with bioflocs in more than one compartment). The advantages of BFT over classical RAS became apparent three decades ago, when different systems based on bioflocs were developed. Currently, there is a trend to merge these two low water demand systems to optimize crops with a reduction in production costs (especially food and electricity). The bio-RAS strategy uses the best and most efficient of each of the previous technologies, with cost reduction combined with

the maximization of technological, zootechnical and animal welfare efficiency and the sustainability of the crops. Bio-RAS has been used in the last decade in a number of low-cost aquaculture projects (Figure 4). In bio-RAS and bioflocs can form in part in one or more compartments, or in the entire circulating water.

Partitioned Aquaculture Systems

The objective of a partitioned aquaculture system (PAS) is to produce zero effluents, where fish are confined in high densities in concrete tanks (raceways) or smaller channels/ponds, around 5% of the total area for the tank and 95% of the pond or lake for recirculation and reuse of water. The fish residues from its catabolism circulate and recycle through the water body where there are high concentrations of algae (fertilized by these resi-

» 14 APRIL - MAY 2023

GREENHOUSES AND POND LINERS

dues), similar to a domestic wastewater treatment, which increases or even doubles the support capacity of the system. By doubling the rate of photosynthesis of algae in these generally isolated baffles and ponds, the rate of removal of nitrogenous, phosphorous and other waste products double, thus doubling the potential maximum feeding rate and the consequent carrying capacity to sustain the system and the fish and shrimp production.

PAS represents a high degree of intensification of previously extensive ponds and reservoirs where phytoplankton predominate. In its various forms, productions in the range of 10–50 tons of tilapia per hectare of surface or 10,000 m3 of total volume are attainable. Its two main variations are increasingly common around the world: (a) IPRS for in pond raceway system with a pond/reservoir/lake holding cages, raceways or containers and (b) SPs for split ponds (Figure 5).

IPRS confines omnivorous fish at high densities in cages or raceways (channels with high water flow) installed along the inside periphery of an existing lake or pond. The water recirculates through the large bodies of water that assimilates the waste from the small, cultivated areas, facilitating the feeding, sampling, protection and harvest of the fish. Although IPRS was originally designed for channel catfish aquaculture in the southern United States, its use expanded and became more popular in the farming

of carp, tilapia and other omnivorous fish in China, India, Brazil, Colombia, Thailand and several other countries.

Integrated Multitrophic Aquaculture (Aquaponics and Ferti-irrigation)

In an integrated multitrophic aquaculture system (IMTA), two or more complementary species with different trophic levels or niches are farmed. For example, tilapia with shrimp and seaweed in brackish water. Another example would be tilapia, silver carp and water lotus in freshwater. In some cases, fish and terrestrial animals and/ or hydroponics (vegetables) could be in the same production system as recirculation with single or multiple loops. The integration between aquatic and terrestrial species (such as plants, pigs, poultry, among others) is maintained with multiple relationships between resources (such as space, water, food or nutrients). Generally, these are shared between different species, thus offering greater potential in terms of technical and economic efficiency and redundancy.

IMTA combines the cultivation of fed species (e.g., tilapia + shrimp) with extractive (species, grazers and filter feeders) feeding on organic matter (echinoderms, molluscs, especially bivalves, micro-crustaceans and worms, other herbivorous fish) and inorganic extracting species (such as phytoplankton and marine macroalgae or hydroponic vegetables). The

goal is to match in the right proportions to create balanced systems that generate environmental and economic sustainability and social acceptability. In addition, the sludge from RAS and bio-RAS systems can be reused as predigested ingredients (highly digestible) in rations for aquatic and terrestrial animals (Figure 6).

Aquaponics is one of the classic examples of IMTA, an interaction between hydroponics and aquaculture, where one crop benefits from the by-products of another, making the respective ecological ‘bottlenecks’ of both systems become strengths, considerably reducing the need for inputs, nutrients and effluent production, unlike when the same systems are run individually (Figure 7).

Comparing the Systems

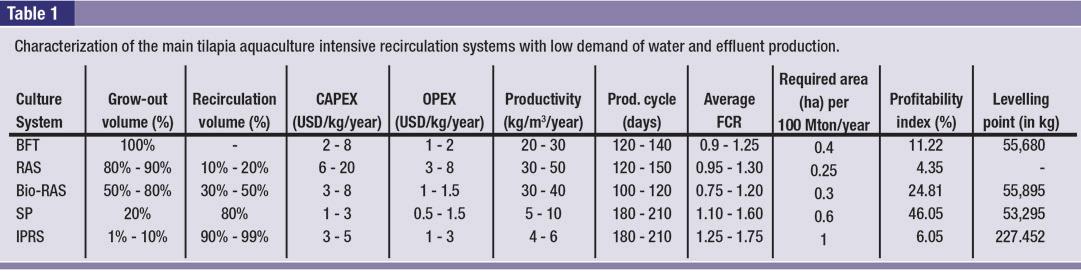

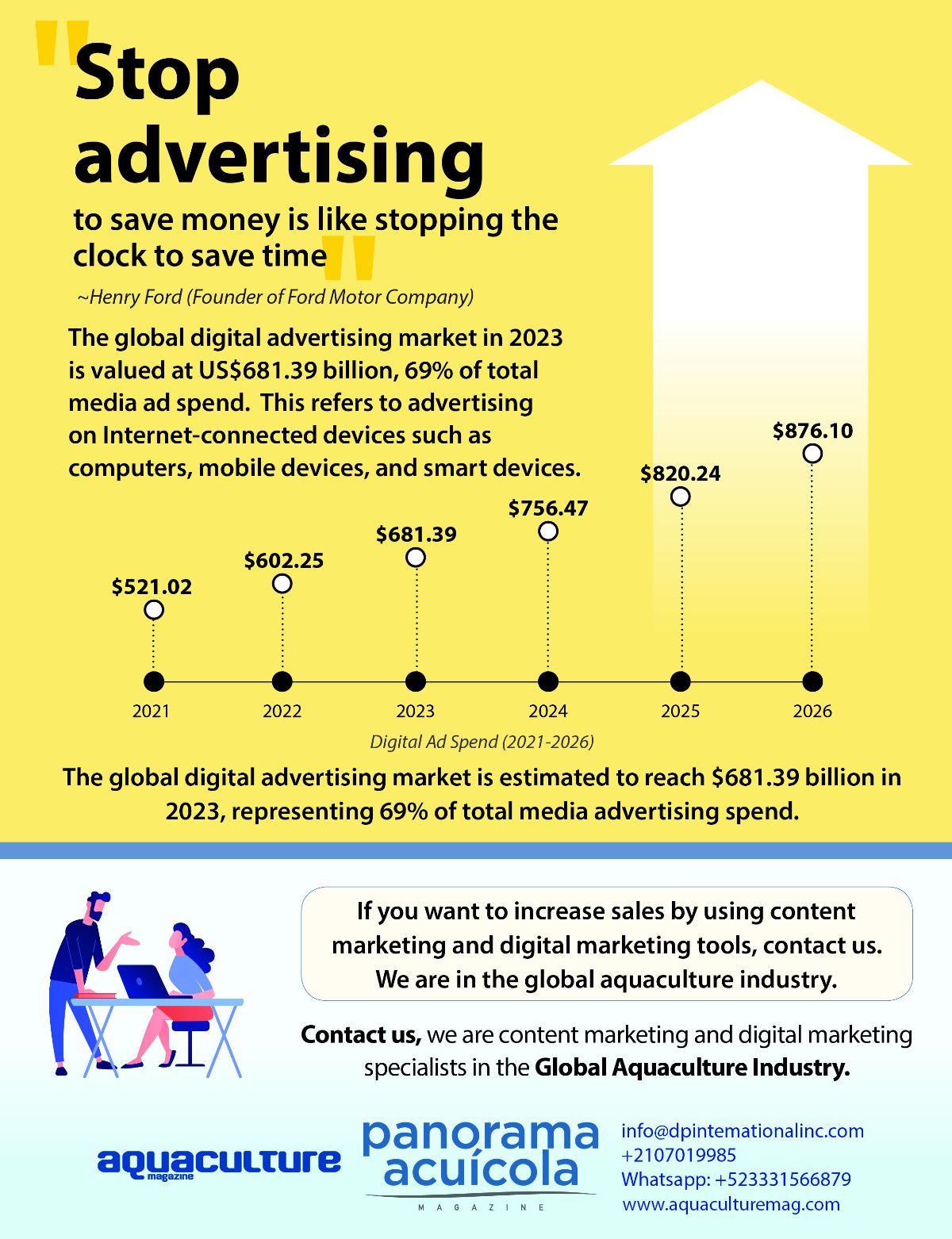

In 2021, the Brazilian Ministry of Agriculture published a booklet with the main characteristics and production costs of several tilapia intensive rearing systems, such as BFT, bio-RAS, ponds and cages from the States of Sao Paulo and Paraná (subtropical climate). The authors stressed that the comparison between technologies should go beyond the observation of the production costs per ton of tilapia. It is very important to evaluate the Capital Expenditure/Operational Expenditure (CAPEX/OPEX), and especially the increasing land costs (not considered in the study, thus favoring the more extensive systems

» 15 APRIL - MAY 2023

such as IPRS and SP), as well as water volumes and the annual production potential of each technology. This last feature altered the financial result and may favor one or another technology. This is the case of BFT and bio-RAS, which could perform 2.6–3.0 cycles per year, with the financial differential of low water requirement production technologies, where management efficiency should reach high levels for the systems to be viable, as well as the appeal of beingenvironmentally sound. This study was later published in more detail with a short economic analysis, and it is summarized together with other references characterizing the systems in Table 1.

Conclusions

Tilapia culture will evolve along with the trends in food production that are increasingly urban, ‘on the roofs of

supermarkets’ and in urban industry facilities, where aquaponics and water saving/ recirculation systems will be the producers of these new forms of Circular Economy. During the COVID-19 years and more recently the war in Ukraine, it is clear that the increasing disruptions of the centralized extractive industries that today sustain the global economy in the five main sectors (materials, energy, information, transport and food/ health), are evolving into a more local model. It is suggested that production and process costs could decrease by an order of magnitude of 10 times by 2030, that is, we will use 90% less natural resources and produce 10 times less waste.

Modern tilapia culture systems with resources flowing in a circular economy will reduce the use of increasingly scarce resources such as water, energy, labor and especially feed

ingredients, minimizing waste production. Novel pre-digested doughlike feeds (FermentAqua®), produced from inexpensive by-products or diet ingredients are replacing traditional diets with low costs and improvements in productivity. The convergence of precision fermentation and water circularity is enabling rapidly falling costs. The recirculation systems characterized in this review include: BFT, RAS, bio-RAS, PAS with SPs and IPRS and IMTA.

Each system has different characteristics in terms of production costs, carrying capacities, FCR, cycles per year, CAPEX/OPEX, financial characteristics, water requirements, production technologies and can be chosen based on specific situations such as land prices, market demands/ distance, water availability and several other parameters.

This is a summarized version developed by the editorial team of Aquaculture Magazine based on the review article titled “THE FUTURE OF INTENSIVE TILAPIA PRODUCTION AND THE CIRCULAR BIOECONOMY WITHOUT EFFLUENTS: BIOFLOC TECHNOLOGY, RECIRCULATION AQUACULTURE SYSTEMS, BIO-RAS, PARTITIONED AQUACULTURE SYSTEMS AND INTEGRATED MULTITROPHIC AQUACULTURE.” developed by: Sergio Zimmermann - R&D, Zimmermann Aqua Solutions, Sunndalsøra, Norway; Anders Kiessling - Department of Animal Nutrition and Management, Swedish University of Agricultural Sciences and Jiasong Zhang- South China Sea Fisheries Research Institute, Chinese Academy of Fishery Sciences. The original article, including tables and figures, was published on SEPTEMBER, 2022 through REVIEWS IN AQUACULTURE. The full version can be accessed online through this link: DOI: 10.1111/raq.12744

» 16 APRIL - MAY 2023 GREENHOUSES AND POND LINERS

This article is sponsored by: REEF INDUSTRIES INC.

Indonesia towards a world aquaculture giant

By: By: Angkasa Putra, B.App.Fish., IPP., CPGAM.*

By: By: Angkasa Putra, B.App.Fish., IPP., CPGAM.*

The Indonesian fishing industry consistently and continuously experiences improvement and progress. This is accompanied by an increasing population, and increasing number of consumers, and the higher technology applied in the field. The next fact that we cannot deny and should be the subject of reflection and devotion is that this country we love, Indonesia, has been named the largest maritime-based archipelagic country in the world. In addition, it has the longest coastline that occupies the second position below Canada. The country, which was once thick with the name ‘Nusantara’, seems to have a hunk of paradise, especially in the marine and fisheries sector. With the area of these waters and different levels of depth, of course, Indonesia has a variety of superior potentials, with a varied, unique, and superior ecosystem of marine fishery resources.

On the one hand, we know the term maritime and marine economic potential, which is closely related to coastal narratives and aims to strengthen, develop, and build the Indonesian economy. As for what is included in Indonesia’s maritime and marine economic sector, it consists of 11 points: capture fisheries, aquaculture, fisheries, and marine products processing industry, marine biotechnology industry, energy and mineral resources, marine tourism, marine transportation, forestry,

The Indonesian fishing industry consistently and continuously experiences improvement and progress. This is accompanied by an increasing population, an increasing number of consumers, and the higher technology applied in the field.

small islands area resources, maritime industry and services, and unconventional natural resources. Referring to Media Investor data, the potential economic value of the 11 sectors reach US $ 1.5 trillion per year, and the newly utilized ones are around 25%.

The 11 sectors above can be developed according to their respective goals, and of course, have one common path, namely advancing and prospering the Indonesian nation. However, other than these 11 sectors, it is the aquaculture sector that can be a ‘caretaker’ or ‘savior’ and has the potential to be developed in order to increase Indonesia’s economic value with a noble goal for progress and prosperity. The reason is, as a strategic geographical country, Indonesia’s aquaculture production potential is also the largest in the world and has the opportunity to continue to be developed throughout the year optimally. In 2016, the total world fishery production 2014 reached 158 million tons, 44.1% of which was produced in the aquaculture sector. Almost 60% of these aquaculture activities are carried out in freshwater cultivation, and 88% of all aquaculture production comes from Asia. Indonesia produces about 17.22 million tons of fresh, brackish, and marine water.

Furthermore, based on data from the Ministry of Marine Affairs and Fisheries of the Republic of In -

Source: MMAF-RI

» 18 APRIL - MAY 2023 ARTICLE

donesia (KKP RI) for 2021, in 2010 aquaculture production exceeded the production of capture fisheries. Until 2019 aquaculture has contributed around 68.40% of Indonesia’s total fishery production, with an average growth of 16% per year during 2000-2019. In the previous data, aquaculture production increased from 994,962 tons (2000) to 1.4 million tons (2004), or an increase of 10.36% per year (Central Research Institute for Aquaculture). In 2018 Indonesia’s aquaculture production

included seaweed of 16,114,991 tons contributed by the top nine species: tilapia (25.84%), pangasius (11.18%), catfish (17.29%), carp (9.93%), goramy (2.96%), snapper (0.14%), grouper (0.39%), milkfish (10.08%), and shrimp (14.19%).

In 2022, KKP RI re-released the latest data related to the total potential area of aquaculture land of 17.91 million hectares consisting of freshwater aquaculture potential of 2.83 million hectares (15.80%), brackish water of 2.96 million hect -

In 2018 Indonesia’s aquaculture production included seaweed of 16,114,991 tons contributed by the top nine species.

» 19 APRIL - MAY 2023

ares (16.50%), and marine of 12.12 million hectares (67.70%), and is estimated to have an economic value of USD 250 billion per year. The targets in 2022: fish: 7.35 million tons, shrimp: 1.34 million tons, ornamental fish: 2.1 million fish, seaweed: 11.85 million tons, and Fish Farmer Exchange Index: 103. On the one hand, coronation was the 2nd largest aquaculture producer in the world has been from 2009, as well as in 2019 according to FAO 2021, where it ranks in the top 10 Global Aquaculture Producers with a value of 15,893,400 tons; 13.23%, after China which came in first (68,423,859 tons; 56.97%), and India in 3rd place (7,800,300 tons; 6.49%).

Recently, KKP RI conveyed to the public that now Indonesia through KKP RI has built the largest modern shrimp pond in Indonesia and international standards. This shrimp farming pond located in Kebumen, Central Java is designed with an area-approach. This shrimp pond is a pioneer in the development of environmentally sound aquaculture, increasing production value in the economy, and a place for work for local residents. In terms of numbers, the area is 60 hectares and the plan is to continue to increase to 100 hectares, 149 plots/ponds, and 125-250 shrimp/ m 2 which is projected to be able to produce 40 tons/hectare in a year, as well as absorb about 300 workers. For additional information, shrimp is one of the leading commodities in the global market besides lobster, crab, and seaweed.

On the other hand, I once wrote an article with the title Great Opportunity for Indonesia to Become a Major Player in the Shrimp World (2022). The narrative is based on the volume of shrimp exports with a significant pattern of increase. It is known that the contribution of shrimp export value to the value of fishery exports reached 36.27%

(2012-2018) while for 2015-2019 the export trend experienced an increase in the volume of 4.21%. Volume shrimp exports were around 162,256 tons (2015), 197,430 tons (USD 1.74 billion) in 2018, and 517,397 tons (production value USD 2.47 billion) in 2019. Data Research & Markets 2021, the international shrimp market is valued at USD 39.24 million (2019) which is projected to grow 1.50% per year with a volume of 4.2 million MT in

2019 and is targeted to continue to grow with an estimated 1.40% per year. The dunia market is estimated to require 13-15 million tons of shrimp supply per year with a supply that has been met based on 2017 data of 8.77 million tons and dominated by the aquaculture sector of 6.09 million tons.

Furthermore, citing data from the International Trade Center 2019, the contribution of the export value of Indonesian shrimp products in

» 20 APRIL - MAY 2023

ARTICLE

2018 to the total value of the world shrimp exports reached 6.84% and occupied the 5th largest position in the world after India (18.63%), Ecuador (12.96%), Vietnam (12.75%), and China (9.01%). With the area of newly utilized aquaculture land still low, and the world’s demand for shrimp being very large, Indonesia has the potential to become the world’s main supplier of shrimp. In addition, the development of science through the path of scien -

tific research/studies, and the world of education must continue to be echgoing (consistent and continuous). KKP RI also has a big target in increasing shrimp production by 250% by 2024 (1,290,000 tons with a production value of USD 6.15 billion). Based on several scientific sources and literature reviews that have been previously mentioned and as a person who has an aquaculture background, the author draws a conclusion that Indonesia has now

Indonesia has the potential to become the world’s main supplier of shrimp.

blazed a path to the world’s aquaculture giants. Large, potential, environmentally friendly, and sustainable aquaculture refers to the concept of a blue economy. So that the mindset and implementation on the ground must be appropriate and in line, so that the narratives are related to the giant who is napping can disappear with the positive progress that continues to be echoed now. Of course, elements of the government, researchers, academia, practitioners, society, and related elements must work together to realize this glorious dream.

» 21 APRIL - MAY 2023

Angkasa Putra, B.App.Fish., IPP., CPGAM. M.Sc Student at College of Fisheries Science, Pukyong National University, Busan, Republic of Korea Telp. (WA): +62 813-6883-2718

From a cell model to a fish trial:

Immunomodulatory effects of heat-killed Lactiplantibacillus plantarum as a functional ingredient in aquafeeds for salmonids

By: Aquaculture Magazine Editorial Team*

Paraprobiotics (dead/inactivated probiotics) are promising candidates in functional feeds to promote growth performance, and modulate intestinal microbiota and enhance the immune response of fish. These benefits were studied at in vivo and in vitro levels in Salmonids, here we present the results.

The rapid development of aquaculture in recent decades can significantly contribute to meeting global demand for animal-derived protein. However, the aquaculture industry faces considerable economic losses during the grow-out period due to smolts of low quality combined with exposure to multi-stressor conditions such as stress due to handling, sea water transportation, delousing, poor water quality and exposure to pathogens, leading to diseases and high mortality. A costeffective way to prevent such losses is the use of functional feeds with immunomodulatory properties during the freshwater phase to promote a more resilient fish. The intestine is an interesting target for this type of approach, since the mucosa associated lymphoid

tissue (MALT) in this organ (GALT) can coordinate both local and systemic immune responses (e.g., inflammation, antigen presentation process, T cell polarization, production of effector molecules and cytokines), which modulate the fish’s response to a challenge. In addition, intestinal microbiota, due to its modulatory capacity, could be the link between diet, immune system and host health.

HK L-137 (Lactiplantibacillus plantarum), has a large potential for functional feeds. Its use has been associated with increased growth performance or immunomodulation in aquaculture species like giant freshwater prawns (Macrobrachium rosenbergii), sea cucumber (Apostichopus japonicus), Red Sea bream (Pagrus major) and Nile tilapia (Oreochromis niloticus).

The research presented in this article evaluates the effect of the paraprobiotic HK L-137 as a bioactive component in functional feed for Atlantic salmon. To study the possible immunomodulating effects of HK L-137, an in vitro trial was performed using a rainbow troutderived intestinal epithelium cell line (RTgutGC) exposed to different concentrations of pre-digested HK L-137 to mimic in vivo gastrointestinal digestion. Following the in vitro trial, an in vivo salmon feeding trial was performed with increasing doses of HK L137.

Materials and methods

The heat-killed strain of L. plantarum (HK L-137) was produced and provided by House Wellness Foods

» 22 APRIL - MAY 2023 ARTICLE

Corporation (Itami, Japan) in the commercial name Feed LP20™. L. plantarum was heat-killed at 70° C for 10 minutes, with a final concentration in the dry product of 2×1011 CFU g-1. As an in vitro model, RTgutGC cells line derived from rainbow trout (Oncorhynchus mykiss) intestinal cells were used.

To mimic in vivo gastro-intestinal digestion, Feed LP20™ was pre-digested before exposing to cells in a two-step in vitro system. To 2 g of Feed LP20™, 9.6 mL pepsin-solution (pepsin 416.7 U mL-1 in 0.084 mM HCl, 35 mM NaCl, pH 2.0) and 0.4 mL chloramphenicol solution (0.1% w v-1) were added in a 50 mL screw cap tube. The solution was incubated in a shaking water bath at 37°C for 2 hours.

After incubation, 675 µL 1 M NaOH was added to inactivate pepsin activity and pH were adjusted to 7.8 by adding 10 mM phosphate buffered saline (PBS). The solution went through another incubation in a shaking water bath at 37°C for 1 hour to stabilize the temperature again. Later, 0.6 mL of an intestinal enzyme cocktail (trypsin 2100 U mL-1, chymotrypsin 100 U mL-1 and elastase 0.2 U mL-1 in 10 mM PBS pH 7.8), was added and incubated in the shaking water bath at 37°C for 6 hours. After digestion, the solution was immediately kept in boiling water for 5 minutes to deactivate the enzymes and the total solution was freeze-dried.

A stock solution was made with a resuspension in PBS at 20 mg mL-1

for later in vitro assays. All compounds and enzymes were supplied by SigmaAldrich, Germany.

The fish trial was conducted at the Center of Sustainable Aquaculture at the Norwegian University of Life Science (NMBU), Ås, Norway. A total of 825 Atlantic salmon (AquaGen Atlantic QLT-innOva SHIELD) were randomly distributed into 15 fiberglass tanks (300 L) with an average biomass per tank of 1,500 ± 2.7 g (55 fish per tank with an average individual weight of 27.3 g). Fish were kept under continuous light in recirculated fresh water with a water supply of 8 L min-1 and average water temperature of 14.9°C. Dissolved oxygen levels were kept above 7.0 mg L-1 in the water outlet. Each experimental diet was supplied in triplicate tanks over a period

» 23 APRIL - MAY 2023

of 61 days. Fish were fed ad libitum with 10% excess by electrically driven belt feeders once a day for 6h. The amount of feed in the feeders was adjusted daily based on the expected fish biomass in the tanks and the uneaten feed in each tank. Uneaten pellets were collected within one hour after feeding from the outlet water settling on a screen for each tank, according to a method described previously. Feed intake, biomass gain and feed conversion ratio and specific growth rate were calculated.

Results

In vitro trial

After exposing RTgutGC cells to different doses of Feed LP20™ for 24 hours, no difference in cell viability was observed even, at the higher exposure levels. RTgutGC monolayer showed no changes in the transepithelial electrical resistance (TEER) after 6- and 24-hours exposure to HK L-137. Nevertheless, a significantly decreased (p-value = 0.002) paracellular permeability was detected after 6-hours exposure to HK L-137.

The detection of immune biomarkers showed that IL-1b production by RTgutGC was higher in cells exposed to HK L137 after 6 (p-value = 0.011) and 24 hours (p-value = 0.021). At the same time, Anxa1 production was significantly lower, but only at the 24-hour time point (pvalue = 0.031). Production of E-cad did not change significantly after HK L-137 exposure at any time point.

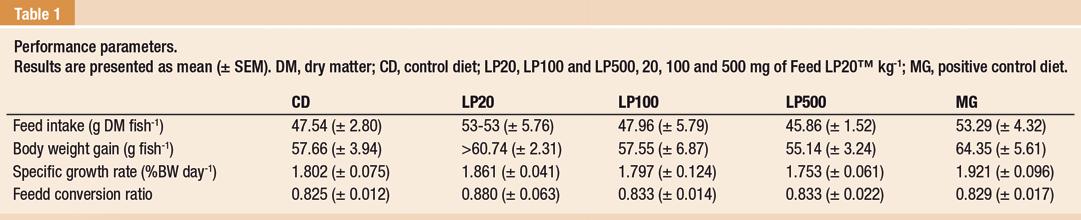

In vivo experiment

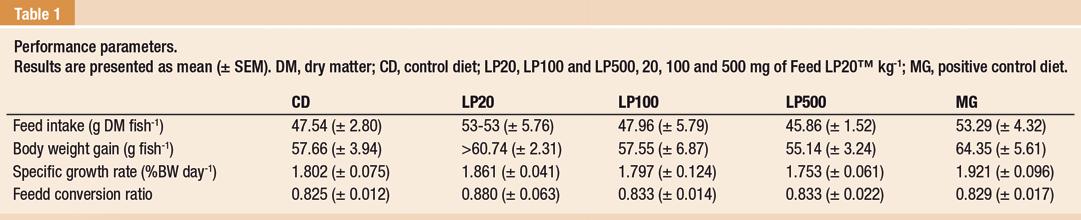

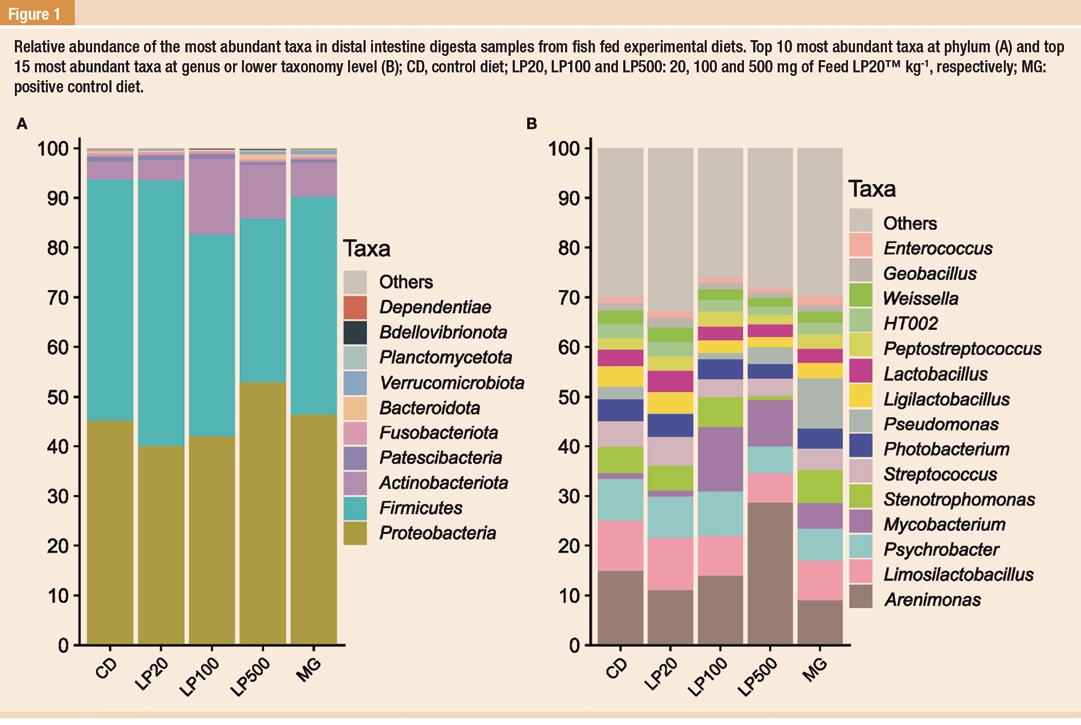

No significant difference was found between dietary groups regarding feed intake, body weight

gain, and specific growth rate and feed conversion ratio, as presented in Table 1.

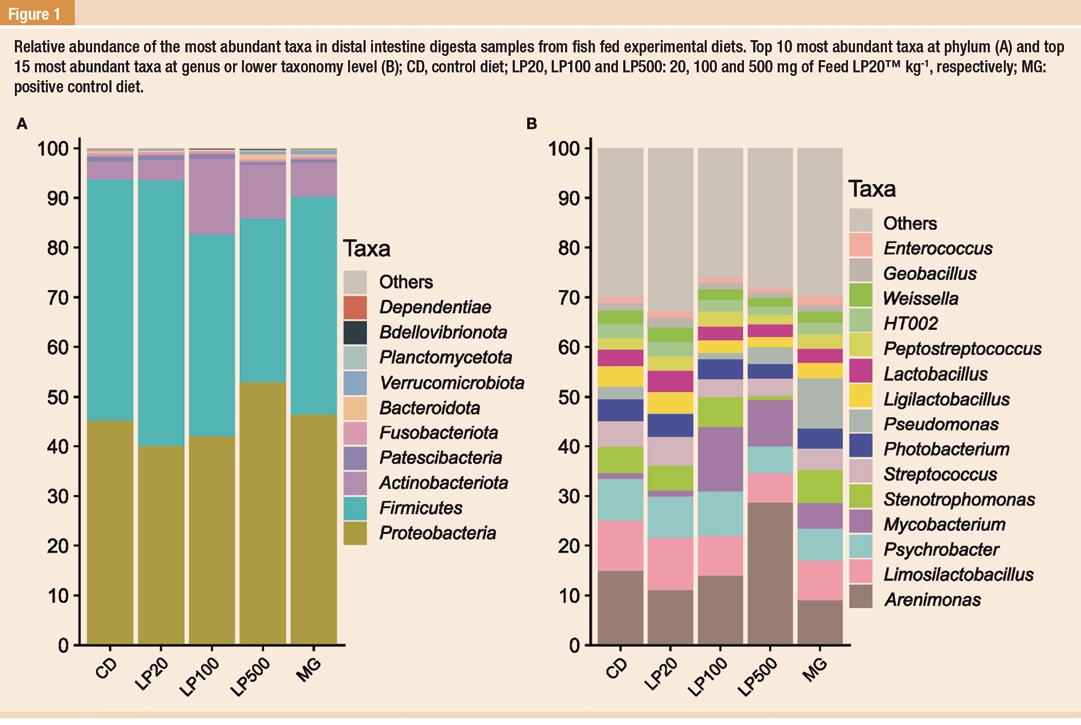

Regarding digesta samples, more than 95% of all bacteria in digesta belong to the phyla Proteobacteria, Firmicutes and Actinobacteriota (Figure 1A). Proteobacteria and Firmicutes relative abundances did not differ from the control group, while Actinobacteriota abundance was significantly increased by the highest inclusion levels of HK L-137 (p-value < 0.0001 and p-value = 0.021, respectively). At the lower taxonomic level, Arenimonas, Limosilactobacillus, Psychrobacter and Mycobacterium were the most abundant genera (Figures 1B).

The relative abundance of Mycobacterium was significantly different from the CD group (except in the LP20 group), while the higher inclusion of HK L-137 led to a lower relative abundance of the genera Stenotrophomonas and Ligilactobacillus .

With a prevalence threshold of 80%, 53 ASVs were identified as core microbiota, with 28 of those shared by all experimental groups. Three ASVs, two classified as Limosilactobacillus and one as HT002, were identified as core ASVs in all the digesta samples.

When studying microbial diversity, alpha-diversity analysis showed that the control diet group (CD) was only significantly different from the positive control (MG) at the observed number of AVSs (p-value = 0.015), indicating increased richness.

Histological analyses showed no significant difference in single fold height between groups or any signs of inflammation in the distal intestinal samples.

The transcriptomic analysis showed that increasing the inclusion level of HK L-137 in the diets induced an increase in differentially expressed genes in the distal intestine. Moreover, DEGs from each diet comparison were used for enriched pathway analysis. LP20 diet induced a down-regulation of 2 terms related to oocyte meiosis and tight junction, but also up-regulated other 5 terms related to ECM-receptor interaction, focal adhesion, vascular smooth muscle contraction, regulation of the actin cytoskeleton and the TGF-beta signaling pathway.

Regarding protein detection, the results showed modulation of biomarkers related to the immune response. The levels of Anxa1 were decreased in the distal intestine of fish fed LP500 (p-value = 0.0335). The same group also had a significant increase in total IgM production in plasma (p-value = 0.0378) compared to the control diet.

Protein levels of IL-1 β and Ecad in distal intestine did not differ between experimental diet groups or in positive control MG. Moreover, when measuring the production of specific IgM against HK L-137, there was no significant difference between groups.

Discussion

Immunonutrition is a promising cost-effective strategy to prevent considerable economic losses during fish production. The effects of fish diseases, and subsequent mortality, are aggravated by several unavoidable stress factors such as handling, seawater transfer and pathogens. By providing functional feeds, the im -

» 24 APRIL - MAY 2023 ARTICLE

mune response of fish can be enhanced, leading to a more robust and healthy fish, able to cope better with such challenges. With this, stress, susceptibility to diseases and mortality can be mitigated leading to improved animal welfare and more sustainable aquaculture production.

At the in vitro level, after exposure to HK L-137, the lack of differences in TEER analysis confirmed the similar integrity of the monolayer in both the control and experimental groups due to the proper development of tight-junctions between adjacent cells. When intestinal integrity is impaired, there is a reduction of digestive function and fish growth and fish become more vulnerable to bacterial infection. Moreover, when Lucifer yellow was added apically, cells treated with HK L-137 reduced the passage of it, indicating a strengthened barrier function of the monolayer.

Interestingly, after 24 hours’ treatment, there was a significant lower production of Anxa1, which supports the previous idea of activation of pro-inflammatory pathways, since Anxa1 has anti-inflammatory properties.

To characterize potential benefits for Atlantic salmon, an in vivo experiment was designed. After 61 days of feeding, no mortality was observed as were no differences in fish performance between groups. Also, there were no signs of inflammation, and the villi height did not change among the groups. Together, these results suggest that HK L-137, at the current inclusion levels, is safe to feed to Atlantic salmon without any deleterious effects.

When studying the intestinal microbiota of Atlantic salmon in this experiment, at the phylum level, there was an increase on the relative abundance of Actinobacteriota in

A cost-effective way to prevent considerable economic losses in aquaculture is the use of functional feeds with immunomodulatory properties during freshwater phase to promote a more resilient fish.

» 25 APRIL - MAY 2023

the LP100 and LP500 groups due to the presence of Mycobacterium genus. Members of the genus Mycobacterium are found in wild and captive fish, and several species are considered pathogens. The route of infection is the oral-intestinal pathway and when infected, fish develop skin ulcers which lead to infection and increased mortality. However, none of these symptoms were observed in this experiment.

Moreover, not all the fish reared in the same tank harbored this genus nor was it identified as top abundant genera in feed and water samples. Interestingly, fish fed MG also presented a relative higher abundance of the genus Mycobacterium compared to the CD group. There was no indication of any consequences of the presence of this genus in the

current study and no reports of Atlantic salmon were found.

Overall, the modulation of the microbiota in the digesta of the distal intestine was minor, which was demonstrated by the lack of significant differences in diversity between the CD and the remaining groups. At the same time, such an observation is not so surprising because we used paraprobiotic HK L-137 in small inclusion levels, ranging from 20, 100 and 500 mg of Feed LP20™ kg-1 feed, (which means 5, 20 and 100 mg HK L-137 kg-1 feed). Because the bacterium was heat-killed, there was no obvious colonization, as was also observed in previous studies. Therefore, there was no competition for space and nutrients with commensal bacteria. Instead, the observed effects of the paraprobiotic on the

HK L-137 (Lactiplantibacillus plantarum), has a large potential in functional feeds. Its use has been associated with increased growth performance or immunomodulation in aquaculture species.

» 26 APRIL - MAY 2023 ARTICLE

modulation of the microbiota would need to act through other pathways, such as epithelial cell metabolism and the immune response, which in turn could modulate the microbiota.

The intestinal epithelium regulates nutrient uptake and represents a crucial barrier function to the extrinsic environment, which when disrupted, is commonly associated with an inflammatory response. In fish fed LP100 and LP500 diets, other terms related to immune response and barrier function were also upregulated, such as phagosome term, MAPK signaling pathways, tight junctions, gap junctions and cell adhesion molecules.

Finally, the current study was performed on healthy fish, while future studies should combine HK L-137 with multi-stressor conditions or pathogen challenges to create an environment closer to commercial fish production.

Conclusion

In the current study, we investigated the potential of HK L-137 at the in vitro level, by exposing a rainbow trout-derived intestinal epithelial cell line (RTgutGC) to HK L-137, and at in vivo level, with different inclusion levels of HK L-137 in pre-smolt feed. This approach was used to improve the experimental design when evaluating novel additives using an immunonutrition approach to promote animal health and welfare.

In both levels, evidence of immunostimulant properties was observed in HK L-137 by modulating cytokines and effector molecules, suggesting its potential in functional feeds for salmonids without compromising fish performance and gut microbiota. This approach creates a baseline for future work involving HK L-137 and other pro and paraprobiotics, both in vitro and in vivo.

This is a summarized version developed by the editorial team of Aquaculture Magazine based on the review article titled “FROM A CELL MODEL TO A FISH TRIAL: IMMUNOMODULATORY EFFECTS OF HEAT-KILLED LACTIPLANTIBACILLUS PLANTARUM AS A FUNCTIONAL INGREDIENT IN AQUAFEEDS FOR SALMONIDS” developed by: Sérgio Domingos

Peng Lei,Byron Morales-Lange, Liv Torunn Mydland and Margareth Øverland - Norwegian University of Life Sciences, Ås, Norway. The original article, including tables and figures, was published on MARCH, 2023 through FRONTIERS. The full version can be accessed online through this link: DOI 10.3389/fimmu.2023.1125702.

» 27 APRIL - MAY 2023

Cardoso Rocha,

A bioeconomic model for the evaluation of a backyard aquaculture system for tilapia (Oreochromis niloticus)

By: Aquaculture Magazine Editorial Team*

Backyard systems are considered agroecosystems in which domestic groups produce various species of animals and plants in a homemade way for food self-sufficiency and economic savings. These promote social and family coexistence and integration to improve food security and contribute to poverty reduction. Labor and land cost savings are the key elements for backyard systems’ economic viability.

Aquaculture is a productive activity, with a growth rate of 46.8% in 10 years (2010-2019). From all aquaculture species, the group of tilapia ranked second among the finfish species, highlighting the production of Nile tilapia (Oreochromis niloticus), which, in 2018, was the third most produced species in the world (FAO, 2020).

Tilapia tolerates very poor water quality conditions and will survive oxygen depletions that would kill most other fish, so they could be stocked in very small ponds at high densities and still thrive. Tilapia will produce acceptable weight gains on various inexpensive, low-quality feeds, reducing pro-

Tilapia could be stocked in very small ponds at high densities and still thrive. Backyard aquaculture systems (BAS) are gaining importance as a source of food and economic input for rural families in Mexico. Here is presented a bioeconomic model of BAS developed for tilapia production at a low scale in rural areas of Mexico.

duction costs. In 2019, the demand for tilapia in Mexico was nearly 300,000 t, of which 168,000 t were produced locally, and the rest (127,981 t) were imported from Asia. Apart from being Mexico the second importer of tilapia in the world after the USA, local demand is growing at an annual rate of 9%; therefore, aquaculture production needs to be increased.

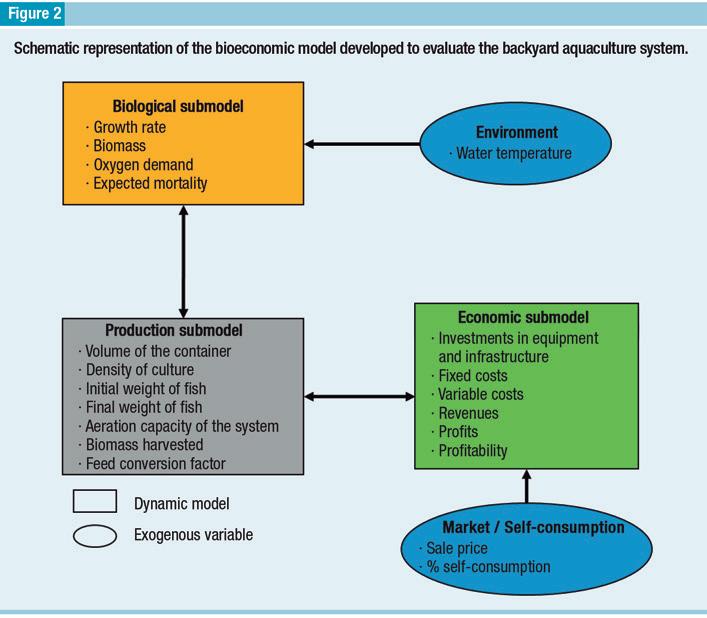

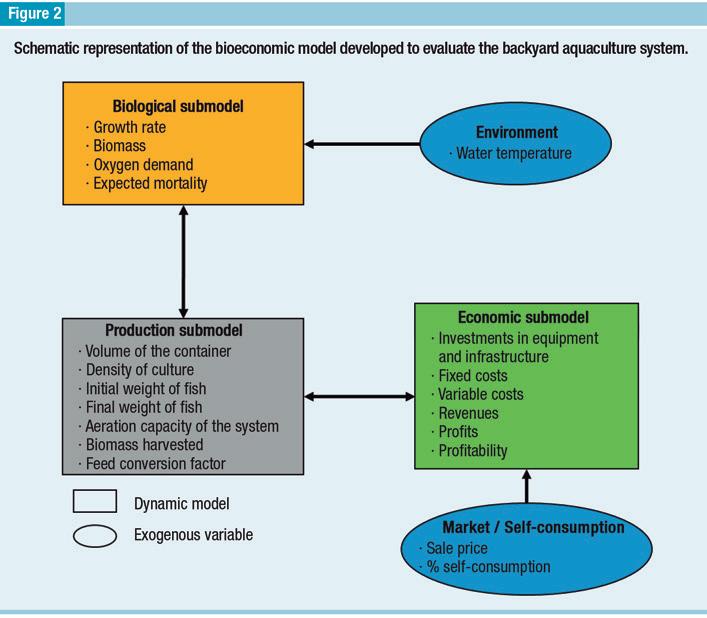

The profitability of backyard aquaculture in different scenarios has yet to be determined. Bioeconomic models are made up of a biological, a production, and an economic sub model, which evaluate the behavior of a system in which the development of a living organism is integrated with certain exogenous and endogenous variables typical of the production system and the market.

In this work, a bioeconomic model composed of a biological, production, and economic sub-model was developed to evaluate the low-cost backyard aquaculture system (BAS) appropriate for rural communities in Mexico, at different sale prices, at certain water temperature conditions, and at self-consumption levels.

» 28 ARTICLE

Materials and Methods

The Backyard Aquaculture System (BAS) was designed as a closed-flow system that was easy to operate, to which partial water exchanges were done depending on the ammonium concentrations. It consists of a 2,800 L plastic water tank (1.86 m diameter × 1.18 m height) to which venture type submersible pumps of 0.046 hp are fitted to recirculate the water at 1,400 L h-1 and oxygenate the water at a rate of 1.2-2.4 kg O2 kW h-1 (Figure 1).

For the model, the biological and culture parameters were those that, in practice, have been demonstrated to be appropriate for tilapia O. niloticus cultivation.

After stocking, the daily activities include temperature checking with a digital thermometer, ammonium concentration determinations using an Ammonia Test Kit (Salicylate), and chlorine (if municipal water is employed) with a free chlorine test kit. Production will depend on the fish’s final weight, which the model will calculate. The sale price was USD 3.62 kg-1 = USD 1.64 lb-1 at an exchange rate of 1 USD = 20 MXN.

The bioeconomic model was composed of three sub-models (i.e. biological, production, and economic) (Figure 2).

The biological sub-model comprised the dependent and independent variables directly influencing growth: biomass, oxygen requirements, temperature, and expected mortality.

Results

The temperature growth coefficient (TGC) was 0.02400, allowed us to build the growth rate curve of Figure 3, and find the final weight of 614 g in the 25 week-cycle. Considering this individual weight and 10% mortality, 186 kg yr-1 of fresh tilapia will be harvested. Five kilograms of initiation, 89 kg of intermediate, and 129 kg of finalization feeds will be employed, giving 223 kg of balanced feed per year, resulting in a 1:1.2 feed conversion factor.

» 29

Considering the oxygen transfer capacity of 1.2 kg O2 kW h-1 of the venturi pump, two pumps will be required to meet the O2 demand until the end of the culture.

Considering the final weight of the fish, the quantity of feed required, and the number of pumps, the total investment required to build and operate the BAS for one year will be USD 1,200 (Table 1), including USD 775 of investment (equipment) and USD 425 of production costs. The equipment list includes scales for biometrics, nets for handling the fish, cleaning tools, a digital thermometer, and a spare venture pump. The operation costs include fry, feed, cleaning reagents, electricity, ammonium and chlorine kits, water, and maintenance.

Total costs per year will be USD 425.26, giving a cost per kg of USD 2.29, considering an annual production of 186 kg. Selling the fish at USD 3.62 kg-1, the gross income (GI) will vary from USD 673 to 503 at 0% and 25% self-consumption, resulting in positive net profit (NP) and net profit margin (NPM), which indicate breakeven values at 25% self-consumption since above this percentage, NP becomes negative. However, profitability indicators at 25% selfconsumption are negative because of the deduction of the discount rate of 8.3% per year. With these indicators, the payback period (PP) will be three and four years for 0% and 10% selfconsumption and longer than five years for 25% self-consumption.

Different scenarios of profitability indicators: cost benefit, net present value (NPV) and internal rate of return (IRR) at different self-consumption percentages and different prices and temperatures were calculated. It is evident that indicators are higher at 0% self-consumption, at the highest temperature tested (32°C) and at the higher sale price.

The annual production of tilapia in terms of the number of fish and weight harvested available for selfconsumption and sales at different

self-consumption percentages demonstrated that at 0% self-consumption, 303 fish and 186 kg will be available for sale.

However, if 10% of production is destined for self-consumption, 31 fish of 614 g and 19 kg will be available to feed the family and will generate revenues of USD 605 by selling 272 fish and 167 kg. At 25% self-consumption, 75 fish and 46 kg

will be available for feeding the family, equivalent to 1.4 fish and 0.88 kg per week. Financial self-sustainability will be reached at this level of selfconsumption since the revenues will be enough to cover the production costs.

Discussion

In this work, evaluating the BAS with the bioeconomic model resulted in

» 30 APRIL - MAY 2023 ARTICLE

a viable, self-sustainable alternative for tilapia production at a low scale in rural areas of Mexico and other Latin American countries. With a low investment of USD 1,200, the BAS could produce high quality food, contributing to food security and poverty reduction, providing extra income for the family.

Regardless of the low-scale production system, BAS is profitable because labor and land have no cost.

At 10% self-consumption, a family of five members could consume 3.8 kg of fish yr-1, a figure that is above the average per capita apparent tilapia consumption in Mexico (3.08 kg ind-1) and in the world (0.9 kg ind-1). At this percentage, there will be a NP of USD 117, which could contribute to the family’s economy. The harvest of fish for self-consumption or sales could be anticipated several weeks before reaching week 25 since not all fish attain the same size simultaneously. So, partial harvests of the larger fish could be done, bringing the advantage of gradually reducing the culture density and availability of food and revenues for the family.

There are several requirements for the successful application of the BAS. This system is suitable for warm areas of Mexico and Latin America,

where average water temperatures above 28°C are registered. Water and electricity supply are also indispensable requirements for the operation of the BAS. Among the project’s risks is the occurrence of diseases caused by bacteria, fungi, and ectoparasites. However, as pointed out before, tilapia is a highly resistant species to diseases, and its susceptibility diminishes with age and size.

The results of the project could be enhanced with several actions. The same family could expand its production capacity by reinvesting their profits to increase the number of tanks. They may also increase revenues by selling the fish live since this finished product presentation is highly valued and getting more popular. The major challenge to overcome is adopting this new activity into the family’s daily routine. The routine includes feeding the fish according to the feeding tables, which indicate the quantity and type of feed to be employed according to the fish size, which implies weighing the fish and selecting the correct feed for the developmental stage. It also includes monitoring water temperature, ammonia, and chlorine (if municipal water is employed) and making water changes if needed. The correct

administration of funds will be important to pay for supplies and save funds for the next cycle. Qualified extensionists could tackle these cultural aspects with appropriate training and supervision. Although the culture parameters of this work were carefully selected, it would be convenient to corroborate results in an experiment in different locations with different temperature regimes. With this experiment, it would be possible to make the necessary adjustments to the model, if needed, for later use as a tool for evaluating existing projects and planning future projects.

In this work, the model selected for growth prediction considered the stages of development and the effect of temperature using the thermal growth coefficient since it was imperative to quantify with high precision the feeding rate and food requirement.

In conclusion, the evaluated BAS proved to be a viable, self-sustainable alternative for tilapia production at a low scale in rural areas of Mexico and other Latin American countries. A specially designed government program is required to promote and finance this activity. Mexico has to try to increase its tilapia production since it has a deficit of nearly 128,000 t yr-1 imported from Asia, the second largest international market for tilapia products. The BAS system could contribute to diminishing the deficit if families in rural areas of Mexico massively adopt it.

This is a summarized version developed by the editorial team of Aquaculture Magazine based on the review article titled “BIOECONOMIC MODEL FOR THE EVALUATION OF A BACKYARD AQUACULTURE SYSTEM FOR TILAPIA (OREOCHROMIS NILOTICUS) developed by: JUAN CARLOS R. DORANTES-DE-LA-O & ALFONSO N. MAEDAMARTÍNEZ - Unidad Nayarit del Centro de Investigaciones Biológicas del Noroeste S.C., Tepic, Nayarit, México. The original article, including tables and figures, was published on DECEMBER, 2022 through LATIN AMERICAN JOURNAL OF AQUATIC RESEARCH. The full version can be accessed online through this link: DOI: 10.3856/vol51-issue2-fulltext-2999

» 31 APRIL - MAY 2023

Half of my professional life working for FAO